Bismuth oxyiodide/bismuth molybdate composite photocatalyst and preparation method thereof

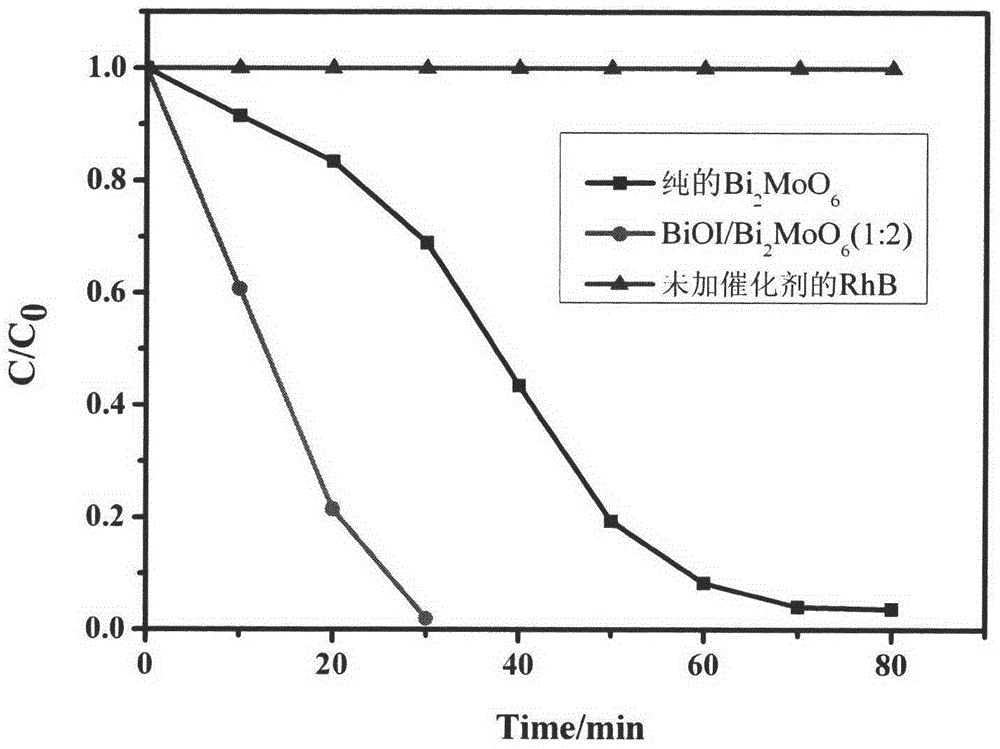

A technology of bismuth oxyiodide and compound light, which is applied in the field of photocatalysis, can solve the problems that limit the large-scale application of bismuth molybdate and the easy recombination of photogenerated electrons and holes, and achieve high-efficiency visible light catalytic activity, easy operation, and accelerated migration rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

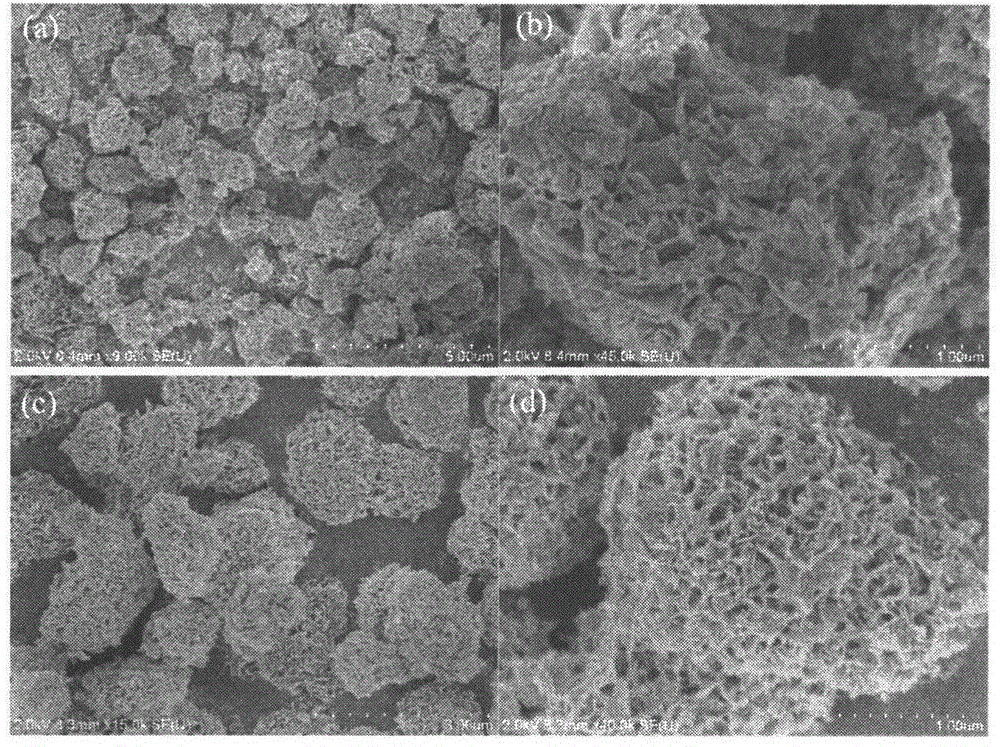

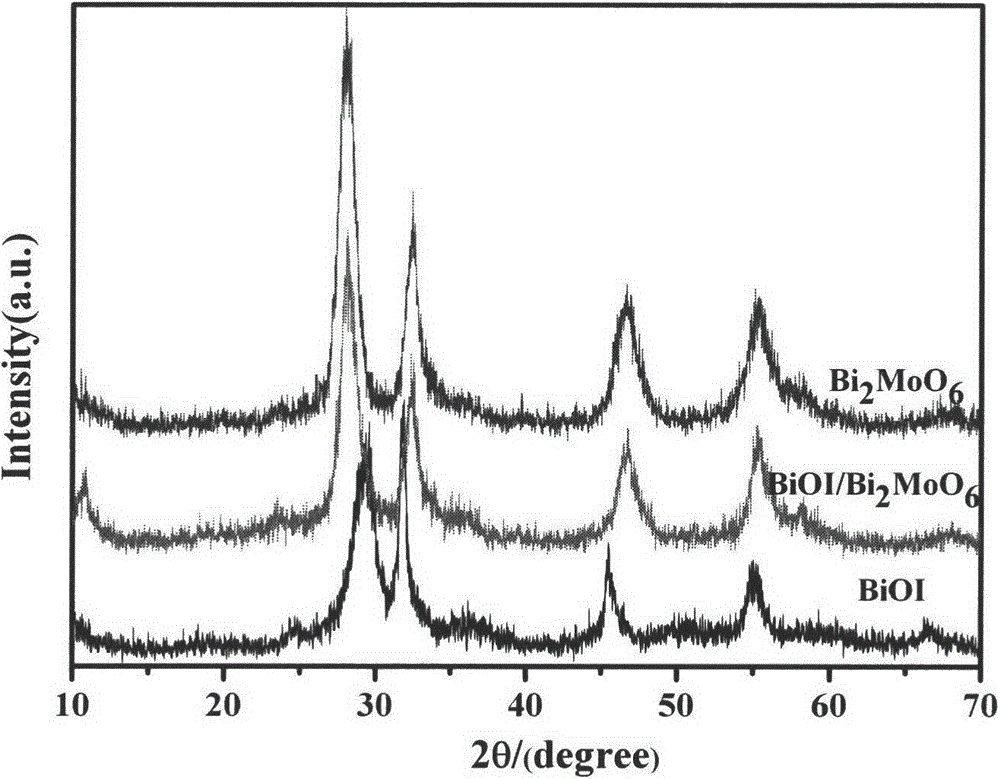

[0015] A kind of preparation method of bismuth oxyiodide / bismuth molybdate composite photocatalyst of the present invention comprises the following steps:

[0016] (1) Preparation of bismuth oxyiodide: first dissolve the bismuth salt in a certain volume of alcohol solution, then dissolve the measured iodide in the alcohol solution, slowly add the latter to the former, stir for 0.5-1h, and then transfer to 50mL In a stainless steel autoclave with polytetrafluoroethylene lining, react at 100-180°C for 10-30 hours, centrifuge the obtained product, and dry it in vacuum at 50-80°C to obtain a bismuth oxyiodide sample;

[0017] (2) Preparation of bismuth oxyiodide / bismuth molybdate composite photocatalyst: Take 0.1-1.0 g of the bismuth oxyiodide sample prepared in step (1) and add it into alcohol solution for ultrasonic dispersion for 0.5-1 h, take a certain amount of molybdate and dissolve it in alcohol solution, then slowly add it into the dispersed bismuth oxyiodide alcohol solut...

Embodiment example 1

[0019] Embodiment example 1: the preparation method of a kind of bismuth oxyiodide / bismuth molybdate composite photocatalyst of the present invention comprises the following steps:

[0020] (1) Preparation of bismuth oxyiodide: first dissolve bismuth nitrate in a certain volume of ethylene glycol solution, then dissolve the metered ratio of sodium iodide in ethylene glycol solution, slowly add the latter to the former, stir for 0.5h, Then transfer it to a 50mL stainless steel autoclave lined with polytetrafluoroethylene, react at 160°C for 15h, centrifuge the obtained product, and dry it in vacuum at 50°C to obtain a bismuth oxyiodide sample;

[0021] (2) Preparation of bismuth oxyiodide / bismuth molybdate composite photocatalyst: Take 0.5 g of the bismuth oxyiodide sample prepared in step (1) and add it into ethylene glycol solution for ultrasonic dispersion for 0.5 h, and dissolve 0.15 g of sodium molybdate in ethylene glycol solution Then slowly add it into the dispersed bis...

Embodiment 2

[0023] Implementation example 2: the preparation method of a kind of bismuth oxyiodide / bismuth molybdate composite photocatalyst of the present invention comprises the following steps:

[0024] (1) Preparation of bismuth oxyiodide: first dissolve bismuth chloride in a certain volume of ethylene glycol solution, then dissolve the metered ratio of sodium iodide in ethylene glycol solution, slowly add the latter to the former, and stir for 0.5h , and then transferred to a 50mL stainless steel autoclave lined with polytetrafluoroethylene, reacted at 160°C for 15h, centrifuged the resulting product, and dried it in vacuum at 50°C to obtain a bismuth oxyiodide sample;

[0025] (2) Preparation of bismuth oxyiodide / bismuth molybdate composite photocatalyst: Take 0.5 g of the bismuth oxyiodide sample prepared in step (1) and add it into ethylene glycol solution for ultrasonic dispersion for 0.5 h, and dissolve 0.11 g of sodium molybdate in ethylene glycol solution Then slowly add it in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com