Microstrip antenna organic composite substrate material and preparation method thereof

A composite substrate and microstrip antenna technology, which is applied in the field of inorganic/organic composite magnetic dielectric substrate materials and their preparation, can solve the problems of unusable antenna substrates, low cut-off frequency, poor flexibility, etc., so as to shorten preparation time, reduce weight and Good volume and mechanical impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] An organic composite substrate material for a microstrip antenna, which is composed of a main phase material and an auxiliary phase material in a mass percentage ratio of 100:100. The main phase material is Co 2 Z-type hexagonal ferrite, its formula molecular formula is (Ba 0.5 Sr 0.5 ) 3 co 2 Fe 24 o 41 ; The auxiliary phase material is polytetrafluoroethylene resin.

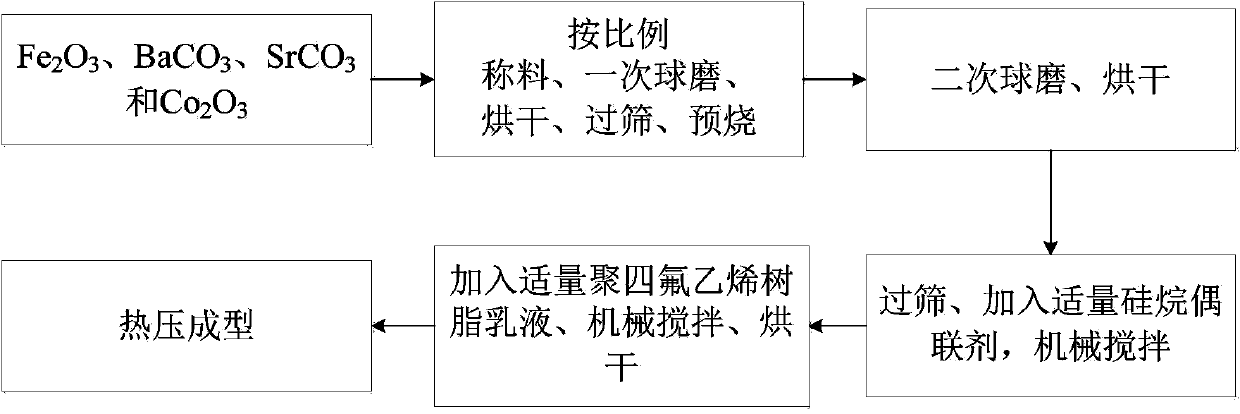

[0026] The preparation method of the above-mentioned microstrip antenna organic composite substrate material is as follows:

[0027] Step 1: Fe 2 o 3 、BaCO 3 , SrCO 3 and Co 2 o 3 As a raw material, according to the above ferrite formula molecular formula (Ba 0.5 Sr 0.5 ) 3 co 2 Fe 24 o 41 The proportion of metal elements in the mixture is converted to the mass percentage of various oxides. After accurate weighing, it is ball milled in a planetary ball mill for 6 hours at a time. After ball milling, the material is dried in an oven at a temperature of 100°C.

[0028] Step 2: After siev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com