Hydrogenated butadiene-acrylonitrile rubber vulcanized rubber with high strength, high pressure resistance and hydrogen sulfide corrosion resistance

A hydrogenated nitrile rubber, hydrogen sulfide-resistant technology, applied in the field of high-strength, high-pressure, high-pressure, hydrogen sulfide-resistant hydrogenated nitrile rubber vulcanizates, can solve the problem of accelerated aging of seals, accelerated aging of rubber materials, and seal materials that cannot withstand high pressure and other problems, to achieve the effect of high pressure resistance and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

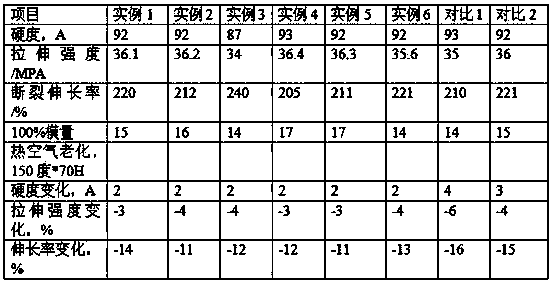

Examples

preparation example Construction

[0029] The preparation method of the vulcanized rubber of the present invention is a conventional method in the art, for example, it only needs to be mixed, re-milled, and vulcanized.

[0030] In the HNBR used in the examples of the present invention, the acrylonitrile content is between 33% and 40%, and the residual double bond content is 0.9% to 10%.

Embodiment 1

[0033] A high-strength, high-pressure, high-pressure, and hydrogen sulfide-resistant hydrogenated nitrile rubber vulcanizate, the formulation of which is as follows:

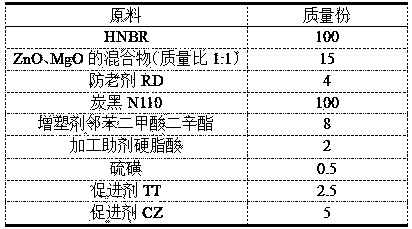

[0034] Table 1:

[0035]

Embodiment 2

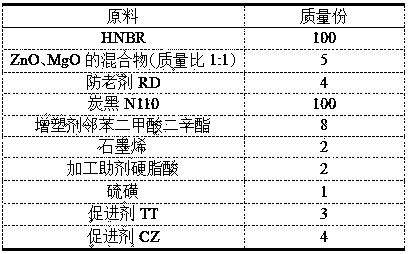

[0037] A high-strength, high-pressure, high-pressure, and hydrogen sulfide-resistant hydrogenated nitrile rubber vulcanizate, the formulation of which is as follows:

[0038] Table 2:

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com