Method for preparing beta-alanine through enzymatically catalyzing hydrolysis of high-concentration beta-aminopropionitrile

An aminopropionitrile, high-concentration technology, applied in fermentation and other directions, can solve the problems of low substrate concentration and difficulty in industrialization, and achieve the effect of reducing ammonia emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

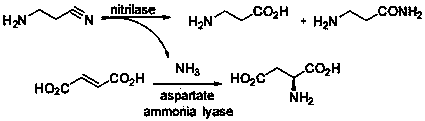

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: the acquisition of highly expressed genetically engineered bacteria

[0019] Design upstream primer (5'-3') TCGCATATGATGGATAGCAACCGACCG, downstream primer (5'-3') TTTGGATCCTCAATTGCGCGCGCGAACG, from Bradyrhizobium japonicum Amplify the blr3397 gene in USDA110, construct the PTXB1 (restriction site Nde I, BamH I) plasmid, introduce the recombinant plasmid into the host bacteria, and ferment and cultivate the engineering bacteria to realize the efficient heterologous expression of nitrilase. Escherichia coli BL21, Rosetta or Origami were selected to screen genetically engineered bacteria with soluble nitrilase in the bacteria, among which the target protein expression of the recombinant bacteria with Escherichia coli Rosetta (DE3) as the host bacteria was relatively good. The engineering bacteria whose expression level of the target protein is not less than 20% shall be used as the engineering bacteria strains for production, and shall be preserved in the...

Embodiment 3

[0022] Implementation example 3 Utilize resting cell blr3397 to catalyze the single hydrolysis of β-aminopropionitrile

[0023] Take 3.5 g of blr3397 resting cells and resuspend them in 30 mL of aqueous solution (6.0 g, 2.5 M) adjusted to pH 7.5 with 6.0 g of β-aminopropionitrile (6.0 g, 2.5 M) after adding 6.0 g of β-aminopropionitrile. After reacting for 5 hours, HPLC detection showed that the reaction was complete (FDAA derivative, mobile phase triethylamine: acetonitrile: 62.5:37.5), the product was purified into a strong cation exchange resin, and 1 M hydrochloric acid was used to slowly flow through the resin, and the dosage was about 2% of the resin volume. -3 times, 1.5 times the bed volume per hour; rinse with water and the pH of the water is about 4.0; use 1 M NaOH to flow through the resin, the dosage and flow rate are the same as 1; wash with water until the pH of the water is about 10.0; use 1M hydrochloric acid to Resin to H + Type, the dosage is 3-5 times the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com