A Supporting Baffle Structure for Steam Generator with Efficient Heat Transfer Performance

A technology for steam generators and supporting partitions, which is applied in steam generation, steam boilers, steam boiler accessories, etc. It can solve the problems of support plate structure corrosion and uneven temperature of secondary side working fluid, etc., to reduce the damage of corrosion, Avoid thermal siphon and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

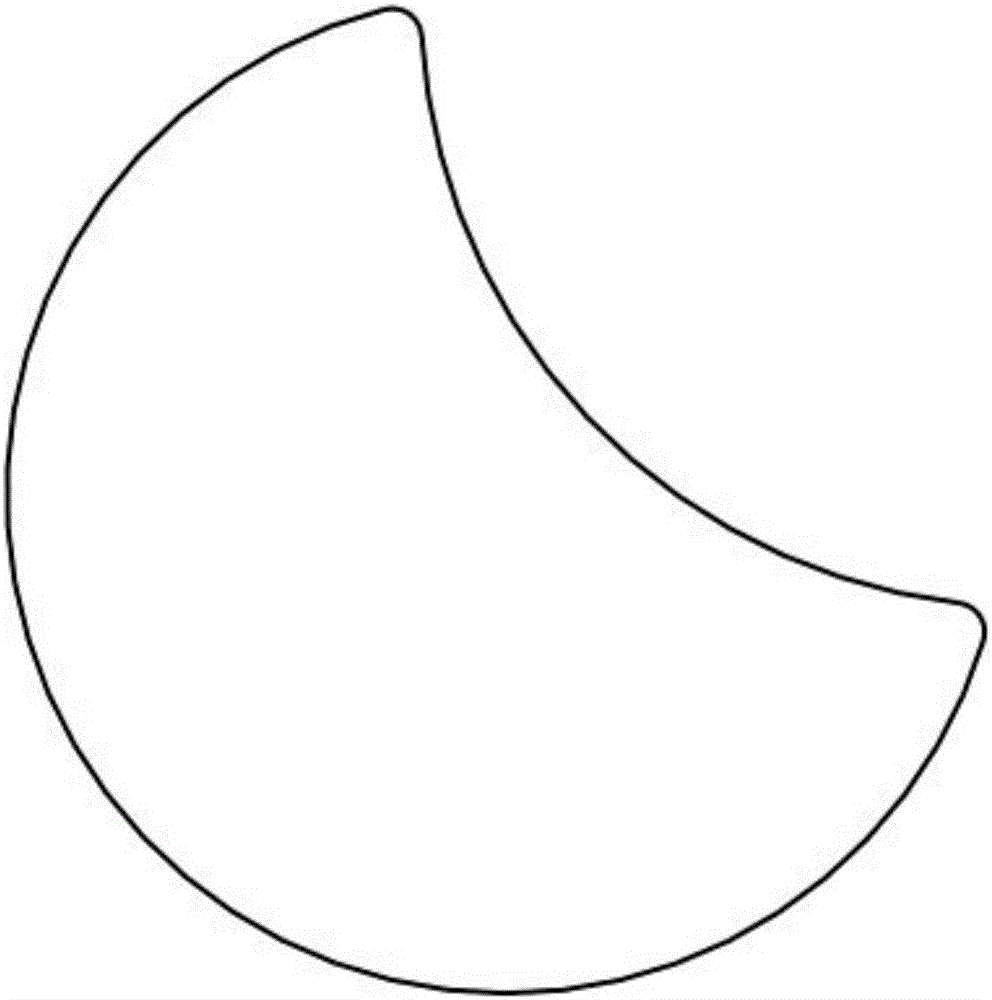

[0041] Such as figure 1 As shown, the shape of the notch of the support partition is a spindle shape formed by the intersection of two circles. The radius of the support partition is R, and a point that is 1.4R away from the center of the support partition is used as the center of the circle, and a circle is made with a radius of 1.2R. The intersection of the circle and the support partition is the shape of the notch; and the two points where the circle intersects with the support partition are rounded with a radius of 0.04R.

Embodiment 2

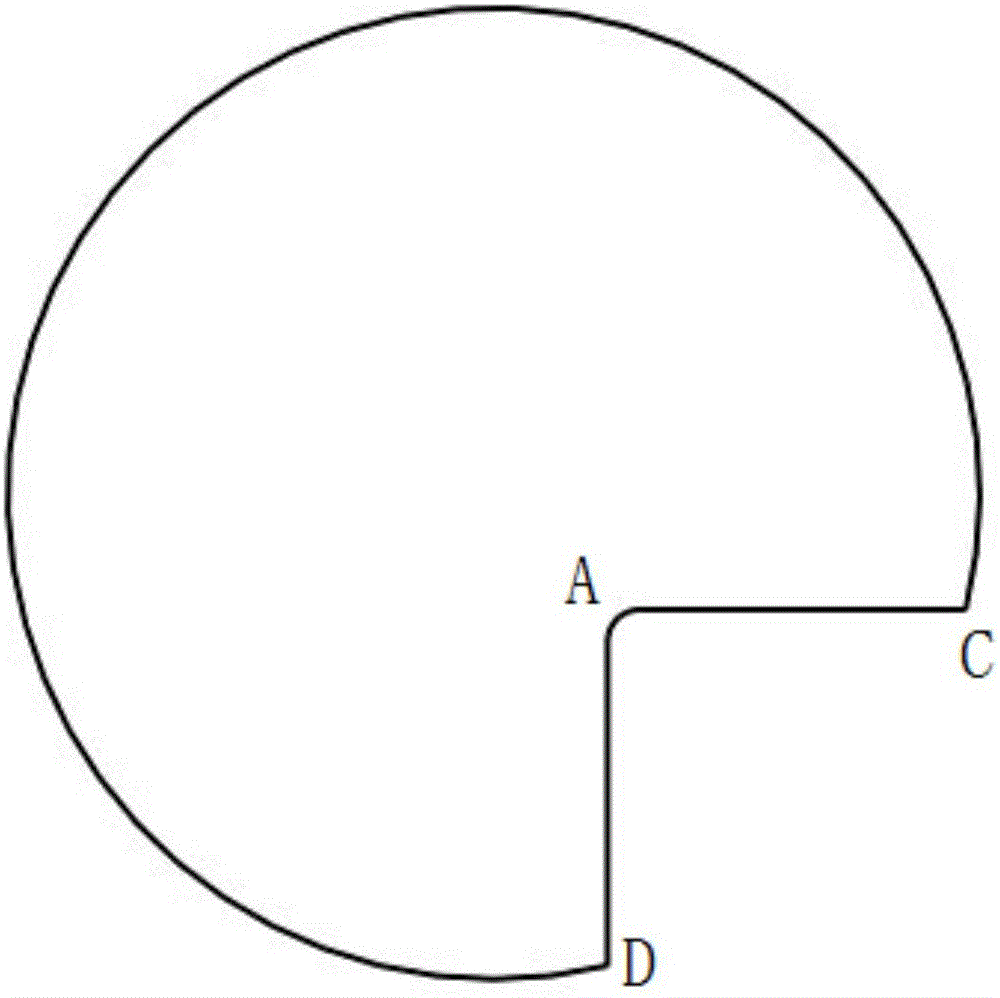

[0043] Such as figure 2 As shown, the shape of the gap of the supporting partition is a single sector, the radius of the supporting partition is R, and the center of the supporting partition is used as the origin to make a plane Cartesian coordinate system, and the point A whose coordinates are (0.1R, -0.1R) is taken, Use point A as the starting point to draw a straight line parallel to the x-axis and y-axis to the positive direction of the x-axis and the negative direction of the y-axis of the plane Cartesian coordinate system, intersect the circle where the supporting partition is located at point C and point D, and connect the line segments AC and Line segment AD, get a fan-shaped gap; and point A is chamfered with a radius of 0.1R, and points C and D are chamfered with a radius of 0.04R.

Embodiment 3

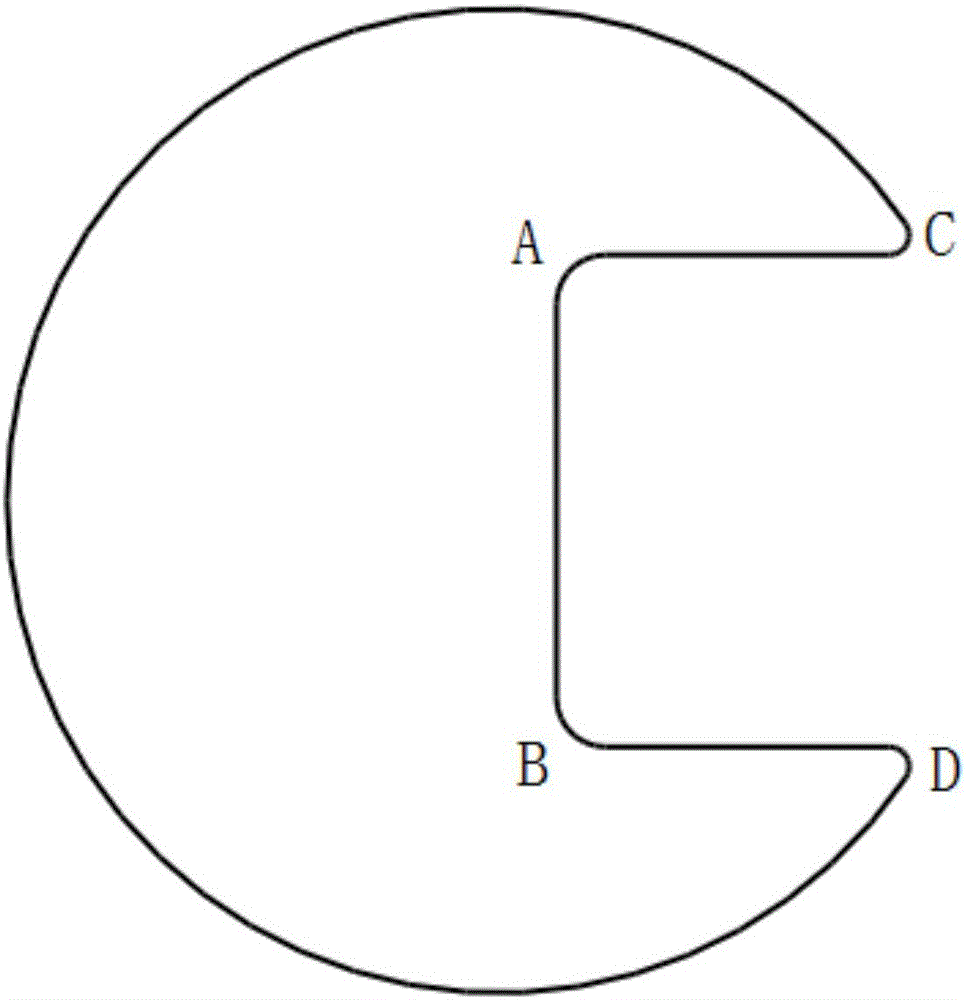

[0045] Such as image 3 As shown, the shape of the notch of the support partition is a square formed by the intersection of a circle and a rectangle, the radius of the support partition is R, and the center of the support partition is used as the origin to make a plane Cartesian coordinate system, and the coordinates are (0.12R, 0.45R ) point A and point B whose coordinates are (0.12R, -0.45R), connect point A and point B to obtain line segment AB, respectively start from point A and point B to the positive direction of the x-axis of the plane Cartesian coordinate system A straight line parallel to the x-axis intersects the circle of the supporting partition at point C and point D, and connects line segment AC and line segment BD to obtain a square gap; and a chamfer with a radius of 0.1R is made at point A and point B, and point C Make a chamfer with a radius of 0.04R at point D.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com