Method for performing lossless identification on brands of steel structure fireproof paints by applying near infrared spectroscopy

A technology of near-infrared spectroscopy and fire-resistant coatings, which is applied in the field of steel structure fire-resistant coatings quality inspection, can solve the problems of no on-site judgment method and judgment basis, large-scale detection equipment, and unsuitable rapid detection, etc., to achieve simple operation and accurate results , analyze the effect quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

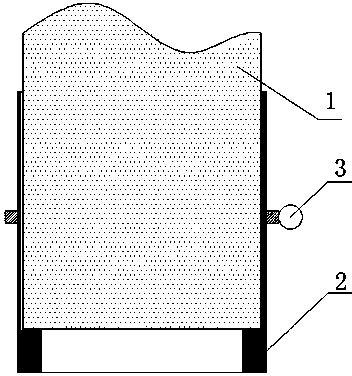

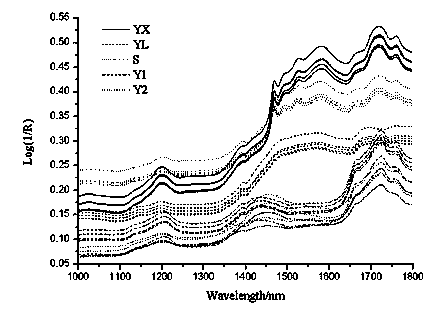

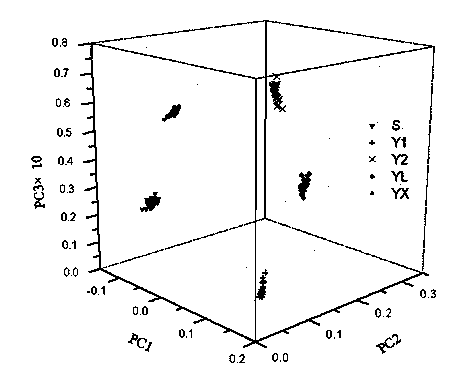

[0017] And below in conjunction with embodiment and accompanying drawing, the present invention is described in further detail. Such as figure 1 , 2 , 3, using SupNIR1520 optical fiber diffuse reflection near-infrared spectroscopy equipment and self-made fiber optic diffuse reflection probe fixing bracket, the fiber optic diffuse reflection probe fixing bracket includes fixing bracket 2 and clamp 3, before collecting Install the fixed bracket 2 on the optical fiber diffuse reflection probe 1, so that the optical fiber diffuse reflection probe 1 is placed on the inner bottom end surface of the fixed bracket 2, and the optical fiber diffuse reflection probe 1 is locked on the fixed bracket 2 through the clamp 3, and fixed in the process of collecting spectra. The bottom of the bracket 2 is in close contact with the surface of the fireproof coating to ensure the consistency of the optical path during each acquisition process. The identification steps are as follows:

[0018] 1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com