Material tracking system and method based on hot backup redundancy detection technology

A detection technology and tracking system technology, applied in the field of material tracking system for roller hearth heat treatment furnaces, can solve problems such as limitations in exploration results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

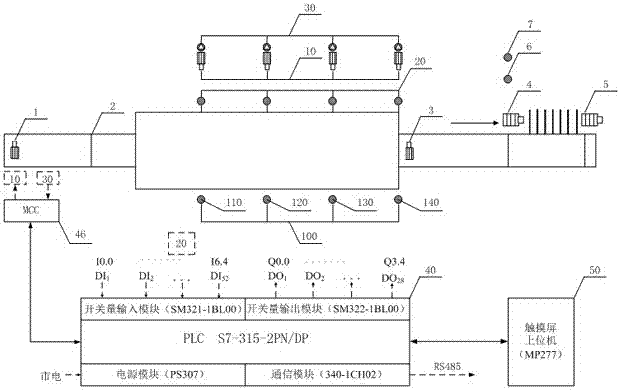

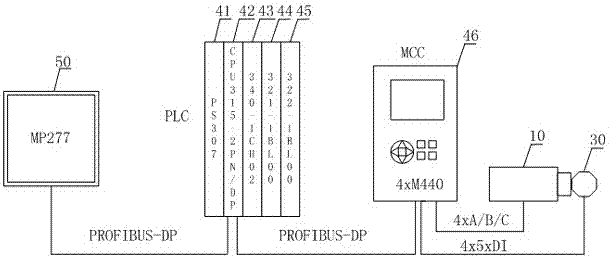

[0045] Such as figure 1 As shown, a material tracking system based on hot backup redundant detection technology includes a transmission detection system and a control system for a roller hearth heat treatment furnace;

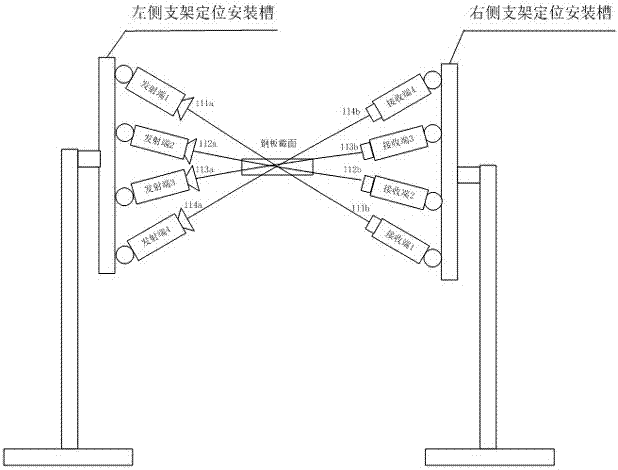

[0046] The transmission detection system of the roller-hearth heat treatment furnace is divided into three subsystems: feeding, furnace and discharge according to the direction of material movement: the feeding subsystem includes a feeding motor 1 and a proximity switch 2, and the furnace subsystem includes 4 in-furnace frequency conversion drives Motor 10, 4 sets of broken link detection devices 20, 4 sets of encoders 30, 4 sets of "3+1" structure laser beamer group 100, and the discharging subsystem includes discharging motor 3, lifting motor 4, and traverse unloading Motor 5, ascending limiter 6 and descending limiter 7; the control system includes the motor control center MCC cabinet 46, the layered PLC lower computer 40 and the touch screen upper computer 50 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com