Flexible package aluminum-plastic membrane applied to lithium ion battery

A lithium-ion battery and aluminum-plastic film technology, which is applied to battery pack components, battery boxes/covers, battery boxes/cover materials, etc., can solve the problem of damage, easy delamination between layers, and adhesive layer that is susceptible to organic solvents damage and other problems, to prolong the service life and solve the effect of interlayer delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

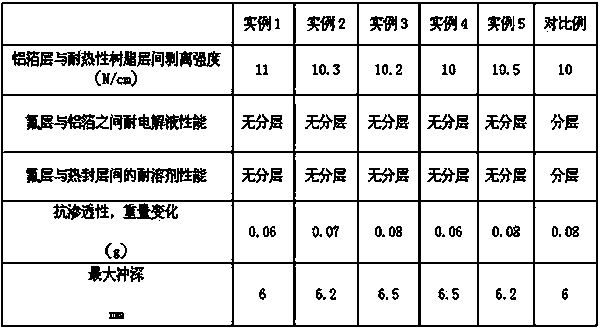

Examples

example 1

[0024] 25 μm double-sided stretched PET film, corona treatment on the surface, and then coated with polyurethane adhesive with a dry thickness of 4 μm, combined with 30 μm aluminum foil treated with silane coupling agent and titanate coupling agent on both sides, and heated on the other surface of the aluminum foil While extruding 20 μm acid-modified polyethylene resin, compound 20 μm corona-treated PVDF fluorine film, while hot-extruding 20 μm acid-modified polyethylene resin on the other surface of the fluorine film, compound 20 μm CPP film. Curing at 44°C to 80°C for 1 to 4 days to obtain an aluminum-plastic film.

example 2

[0026] 30μm double-sided stretched PA / PET composite film, surface corona treatment, then coated with 4μm dry polyurethane adhesive, dry composite 40μm aluminum foil with chrome treatment on both sides, hot extruded 30μm chlorine on the other surface of the aluminum foil At the same time as the polypropylene resin is melted, a 30 μm corona-treated PVDF fluorine film is compounded, and a 20 μm polyethylene and acrylic acid copolymer is thermally extruded on the other surface of the fluorine film, and an 80 μm CPP film is compounded. Curing at 44°C to 80°C for 1 to 4 days to obtain an aluminum-plastic film.

example 3

[0028] 20μm double-sided stretched PA film, corona treatment on the surface, then coated with epoxy resin adhesive with a dry thickness of 4μm, dry lamination of 50μm aluminum foil with chrome treatment on both sides, and hot extrusion of 50μm metal ions on the other surface of the aluminum foil At the same time as polyethylene resin, 25μm corona-treated PVF fluorine film is compounded, while 50μm chlorinated polypropylene resin is thermally extruded on the other surface of the fluorine film, and 50μm triethylene propylene rubber / copolymerized PP co-extruded CPP is compounded film. Curing at 44°C to 80°C for 1 to 4 days to obtain an aluminum-plastic film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com