Method for producing hematite for iron production

一种制造方法、赤铁矿的技术,应用在氧化铁/氢氧化铁、氧化铁、工艺效率的提高等方向,能够解决很难有效的原料、不能忽视分级矿石成本和劳力、铁品位低等问题,达到废弃成本减少、实现环境风险、构筑容易的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

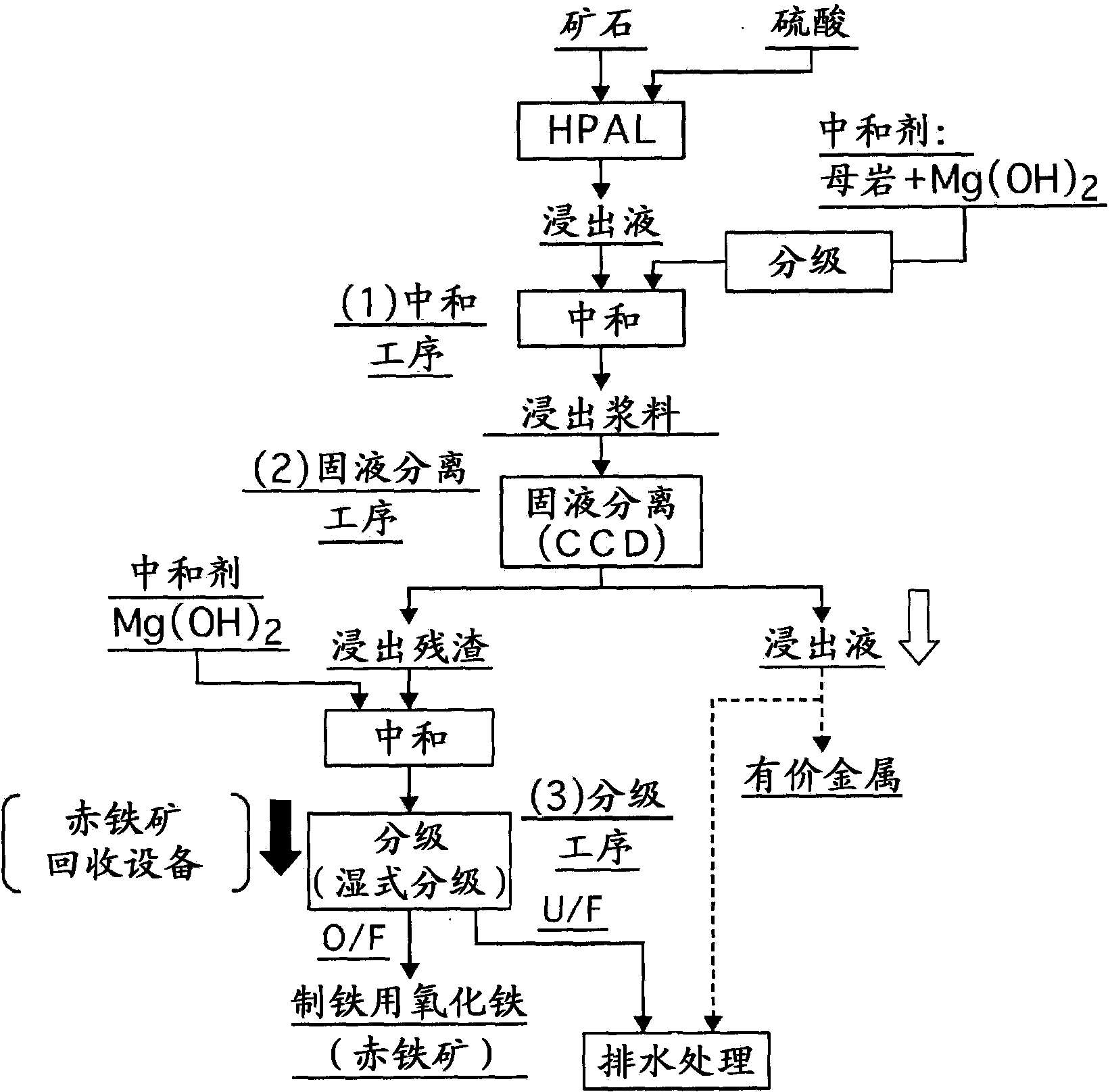

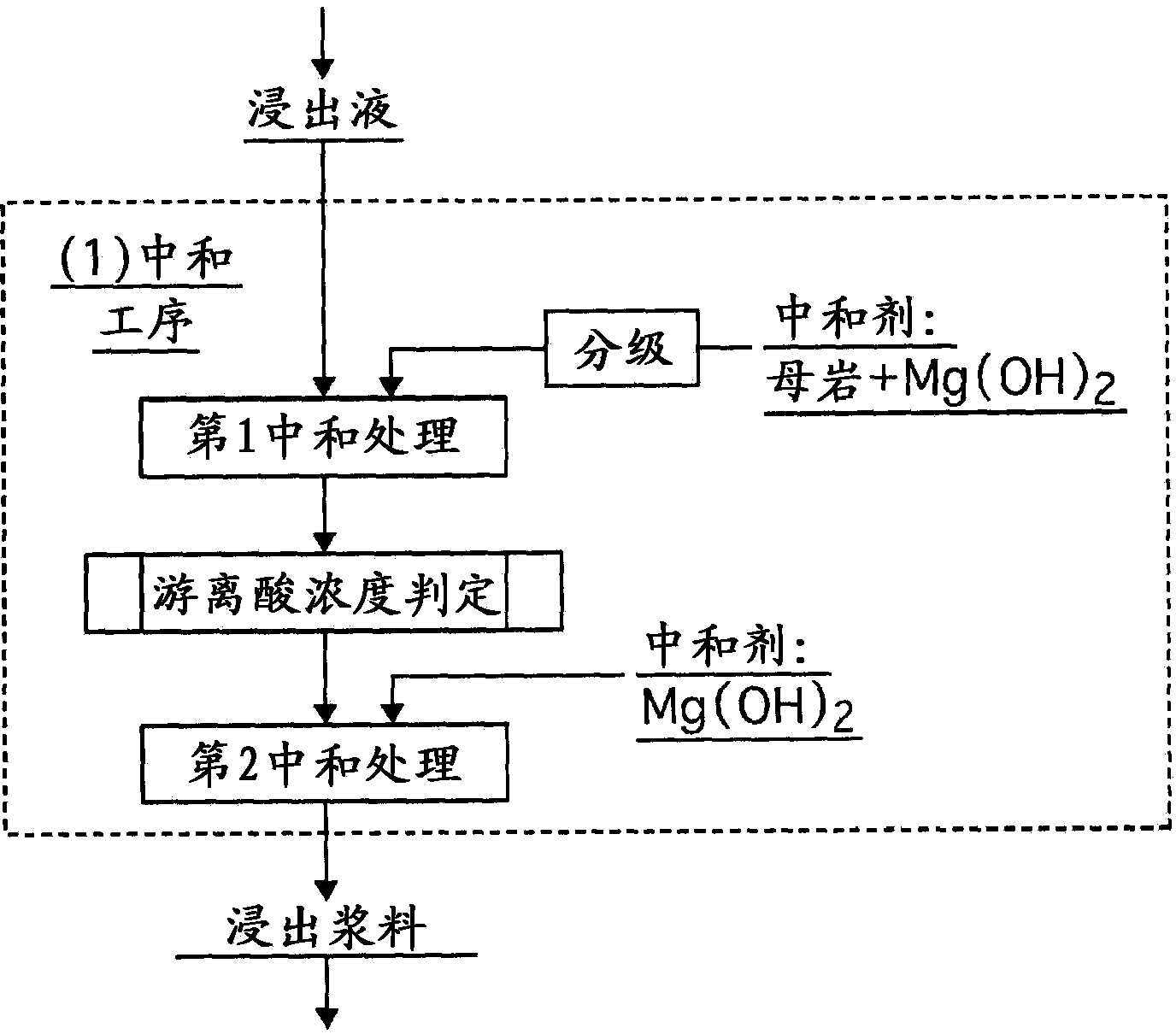

Method used

Image

Examples

Embodiment 1

[0079] After adjusting nickel oxide ore with a nickel grade of 1% and an iron grade of 46 to 48% into a slurry of 30 to 40% by weight, it is mixed with 98% by weight of sulfuric acid, and then the slurry is charged into a pressurizing device and heated to 240~250°C and maintain for 1 hour, leaching the nickel in the ore.

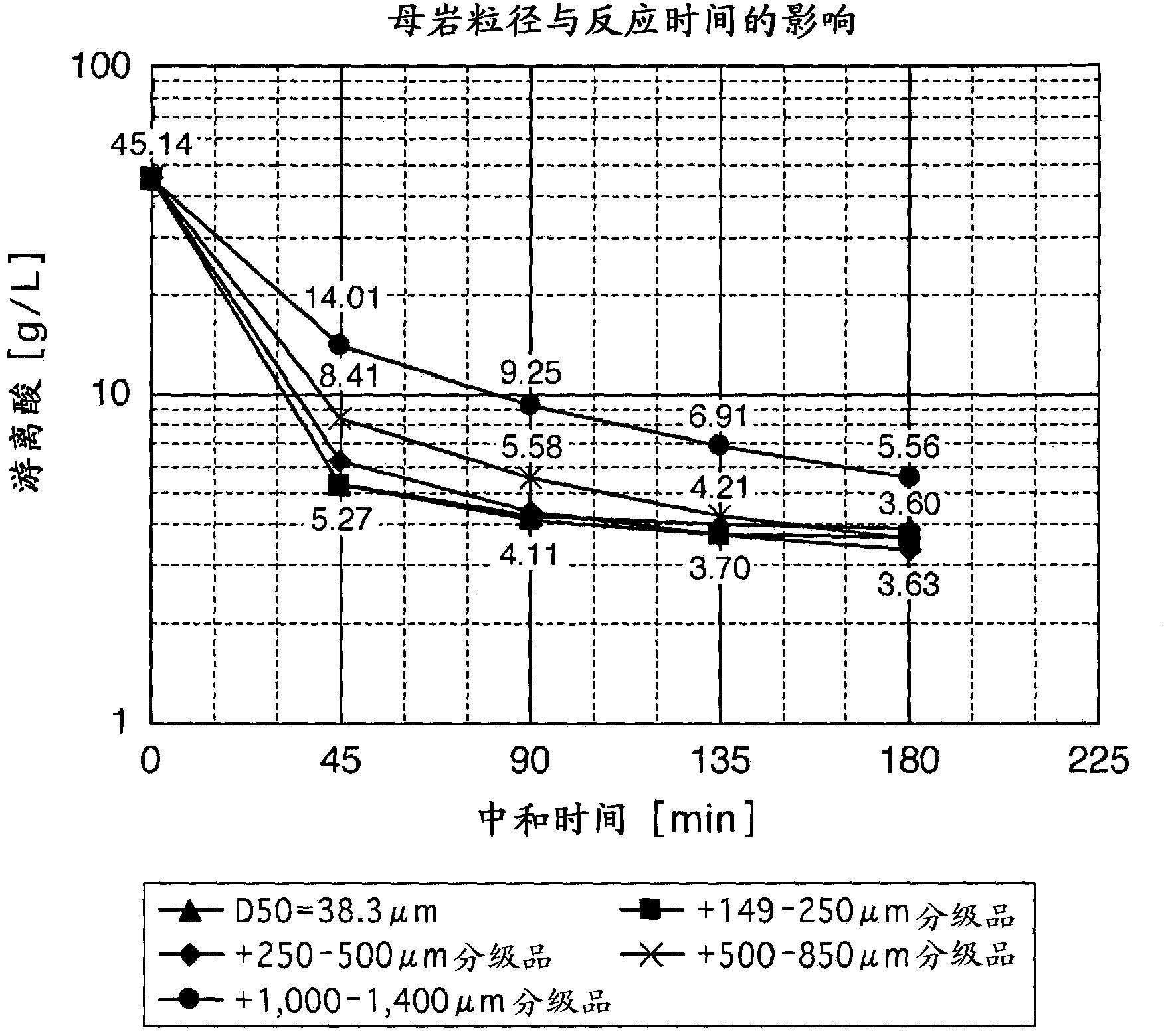

[0080] After leaching, cooling to about 70°C, the remaining acid was neutralized by adding parent rock of the composition shown in Table 1 excavated from the same mine.

[0081] Next, the slurry containing the neutralization residue after neutralizing the remaining acid was solid-liquid separated using a suction filter and a filter bottle, and separated into a leachate and a neutralization residue. The iron grade of the neutralized residue was 49.9% (71.4% in terms of hematite grade).

[0082] Next, the obtained neutralized residue was supplied to a wet cyclone and classified into underflow (U / F) and overflow (O / F).

[0083] Table 2 shows classification co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com