Method of slime control in paper pulp manufacturing process

A control method and process technology, which is applied in the addition of pulp control agent, chemical instruments and methods, papermaking, etc., can solve problems such as reduced effect, and achieve the effect of inhibiting decomposition and high addition amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

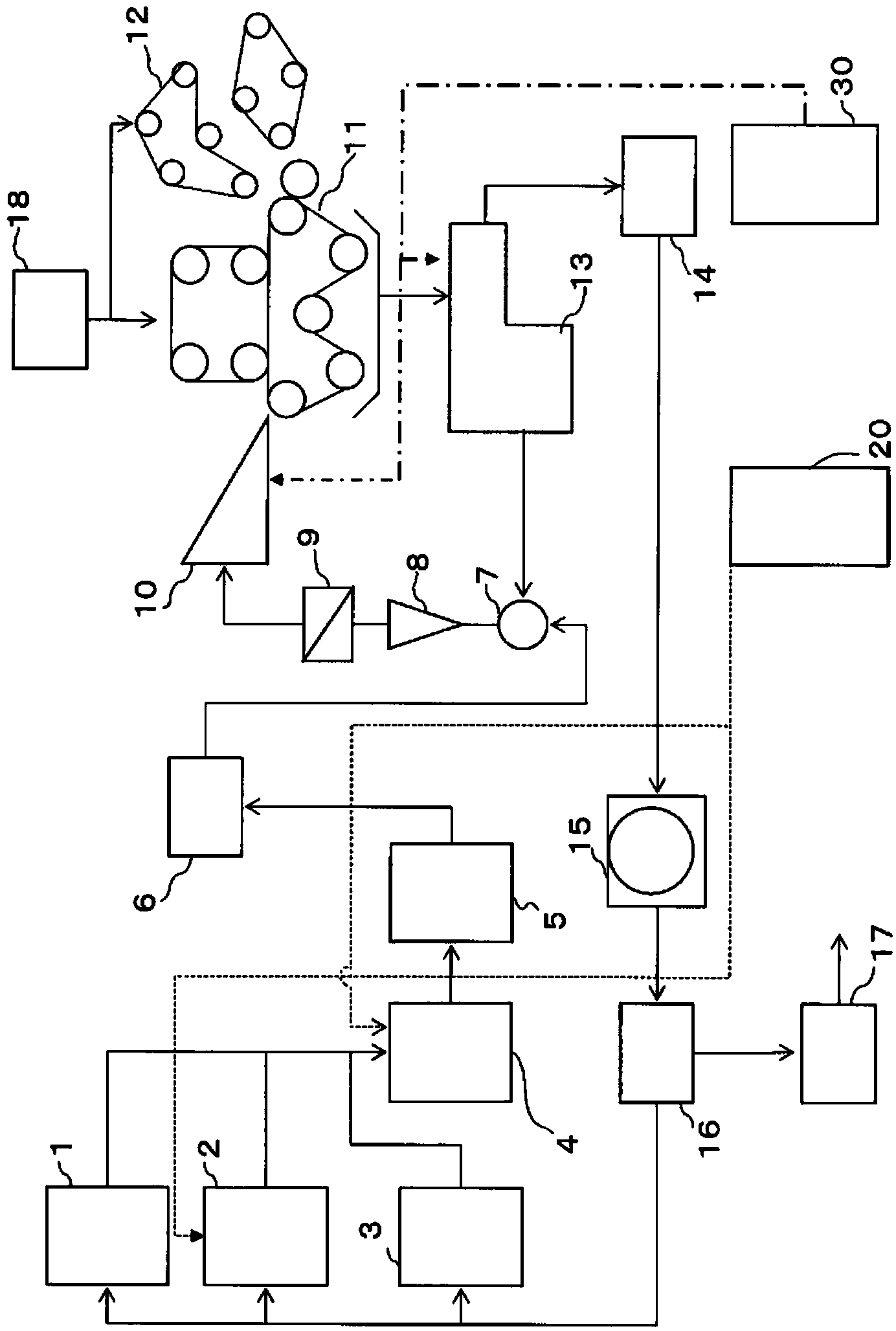

Method used

Image

Examples

Embodiment

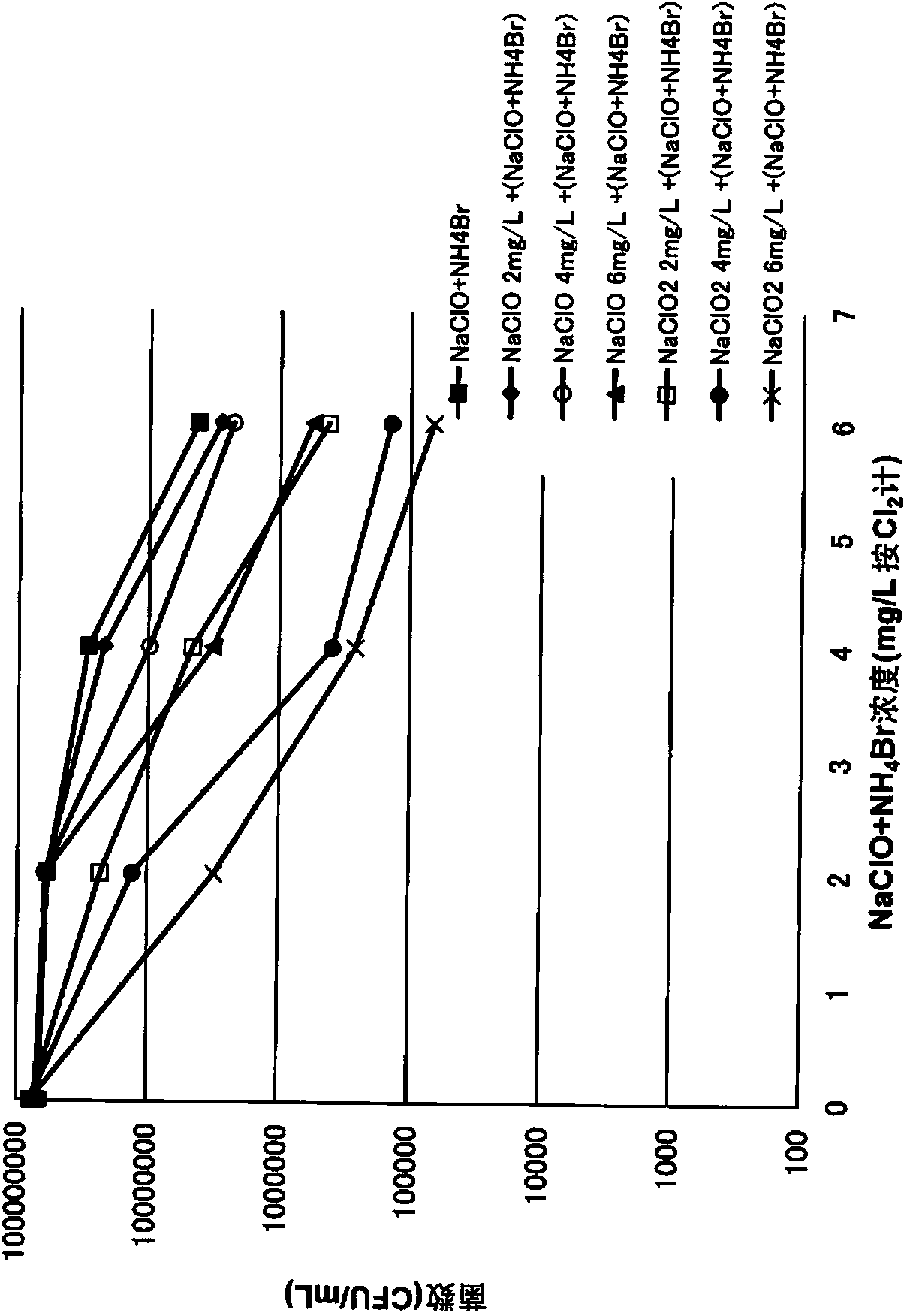

[0047] Hereinafter, experimental examples corresponding to examples of the present invention or comparative examples are listed, and the present invention will be more specifically described.

[0048] It should be noted that the reagent used in the following experimental examples is sodium chlorite (NaClO 2 ), sodium hypochlorite (NaClO) and inorganic fungicides (mixed product of NaClO and ammonium bromide, NaClO:NH 4 Br=1:1 (molar ratio of Cl to N)).

[0049] In addition, in the measurement of the residual chlorine concentration, three of the DPD method (total chlorine), the DPD method (free chlorine), and the iodine titration method (JIS K0101) are implemented.

[0050] In the DPD method (total chlorine), the determination of NaClO and (NaClO+NH 4 Br) Both, NaClO not determined 2 .

[0051] In the DPD method (free chlorine), only NaClO is measured, and inorganic fungicides (NaClO+NH 4 Br) and NaClO 2 .

[0052] In the iodine titration method (JISK0101), determination ...

experiment example 1

[0061] [Experimental Example 1 (Example of the present invention)]

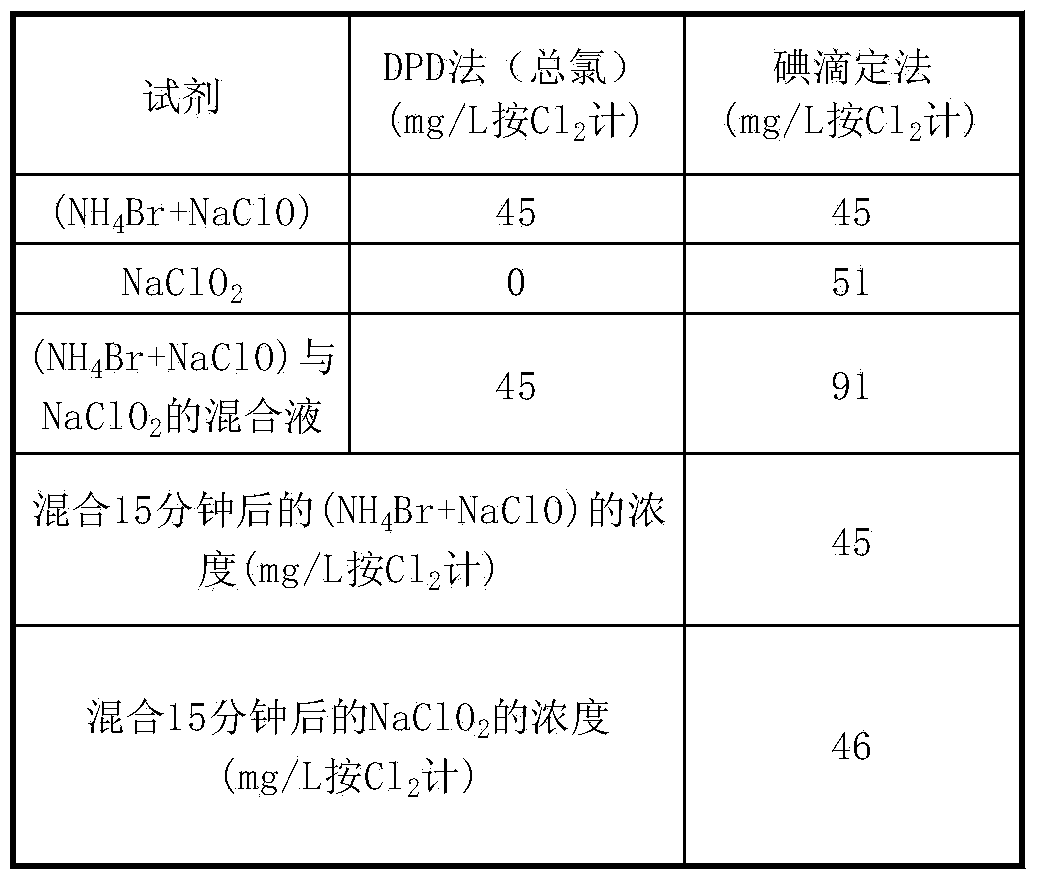

[0062] NaClO 2 With inorganic fungicides (NaClO+NH 4 Br) were diluted to Cl 2 Calculate about 50mg / L and mix in equal amounts. After mixing, the residual chlorine concentration was measured 15 minutes later, and the results are shown in Table 1.

experiment example 2

[0063] [Experimental example 2 (comparative example)]

[0064] Use NaClO instead of NaClO 2 , except that it was mixed in the same manner as in Experimental Example 1, and the residual chlorine concentration was measured. The results are shown in Table 2.

[0065] Table 1

[0066] Table 1. NaClO 2 with (NH 4 Chlorine concentration when Br+NaClO) mixed

[0067]

[0068] Table 2

[0069] Table 2.NaClO and (NH 4 Chlorine concentration when Br+NaClO) mixed

[0070]

[0071] As shown by the results of Experimental Example 1 and Experimental Example 2, NaClO and inorganic fungicides (NaClO+NH 4 In the experimental example 2 of Br), the two reagents were clearly decomposed, on the other hand, mixed with NaClO 2 With inorganic fungicides (NaClO+NH 4 In Experimental Example 1 of Br), the decomposition of the two reagents was not confirmed, and it can be seen that by adding chlorite (salt) instead of hypochlorite to the water system in the pulp manufacturing process, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com