Electrode material, method for manufacturing electrode material, and secondary battery

A technology of electrode materials and raw materials, applied in non-aqueous electrolyte batteries, lithium batteries, battery electrodes, etc., can solve problems such as poor charge-discharge cycle characteristics, low sulfur utilization rate, and failure to reach cut-off voltage, and achieve improved utilization and utilization. rate improvement, high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] Example 1 relates to the electrode material, the method of manufacturing the electrode material, and the secondary battery according to the first embodiment and the second embodiment of the present disclosure.

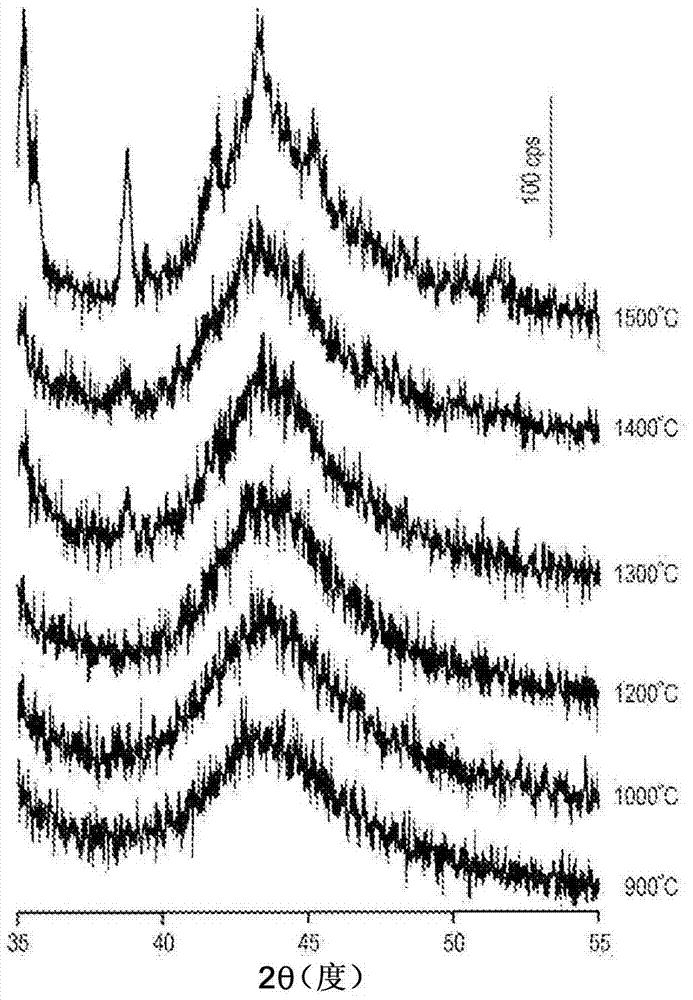

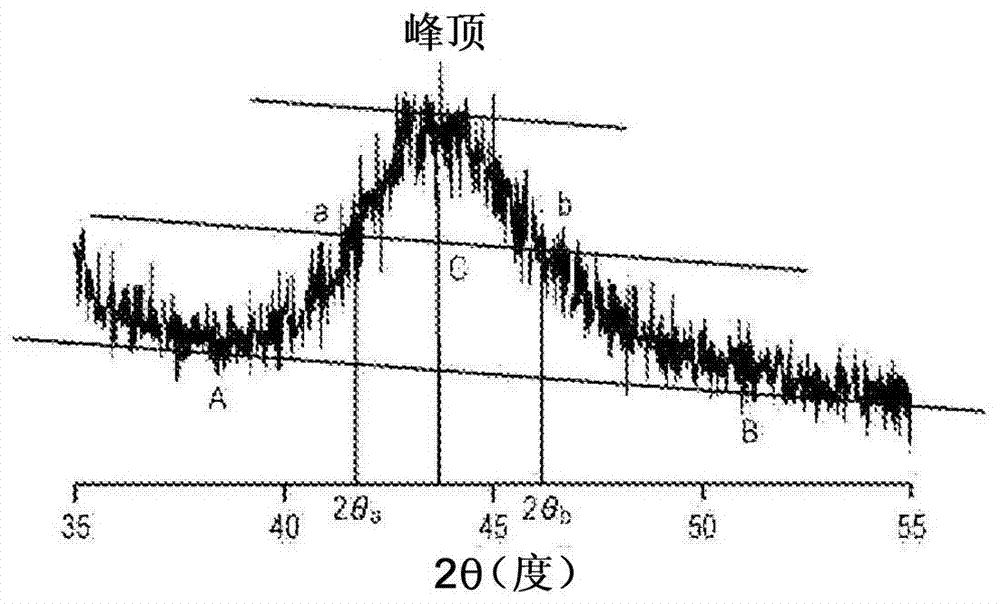

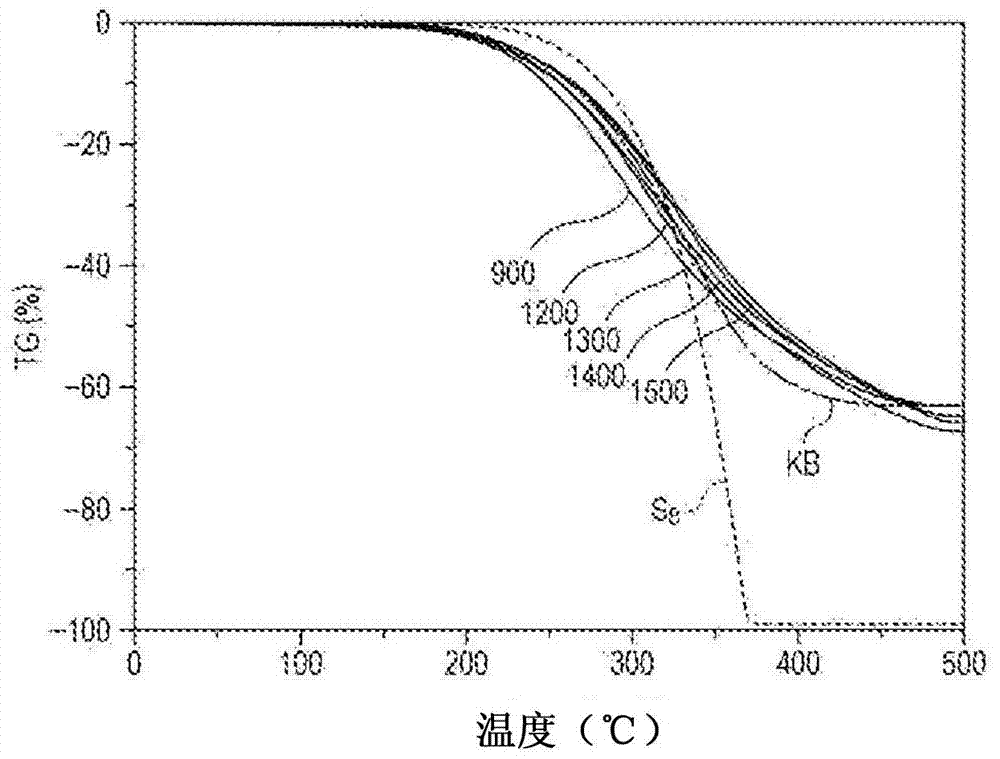

[0102] The electrode material for the secondary battery of Example 1 is made of a porous carbon material exhibiting a (100) plane or (101 ) half-width of the diffraction intensity peak of the plane. Alternatively, the electrode material used in the secondary battery of Example 1 is made of porous carbon material, wherein, when the porous carbon material and S 8 The absolute value of the differential value of the mass (absolute value of -dW / dt) obtained when a mixture of sulfur is subjected to thermal analysis (temperature is used as a parameter) exhibits a value greater than 0 at 450°C and 1.9 or more at 400°C value (preferably, 2.0 or greater).

[0103] The secondary battery of Example 1 includes an electrode made of a porous carbon material exhibiting a (100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com