Process for preparing fly larva albumen powder by enzymatic hydrolysis of fly larvae

A technology of protein powder and enzymatic hydrolysis, applied in the direction of protein food components, protein components of waste, protein composition of microorganisms, etc., can solve the problems of large nutritional loss of protein, complex products, complex protein raw materials, etc., and achieve the goal of increasing the degree of hydrolysis Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Get fresh fly maggot, add and be equivalent to its weight 10 times of water refining, adjust its pH to be 6.5, then add the enzyme composition that is equivalent to fresh fly maggot weight 3% (the weight ratio of composite protease, neutral protease and flavor protease is 1:1:0.5), heat up to 50°C and keep enzymatic hydrolysis for 5 hours, inactivate the enzyme, filter, collect the filtrate (the degree of hydrolysis is 61%), concentrate under reduced pressure, and spray dry to obtain the fly maggot protein powder.

[0014] The obtained fly maggot protein powder is added with water to form a solution with a mass concentration of 5%, which has no bitter taste and a little fishy smell.

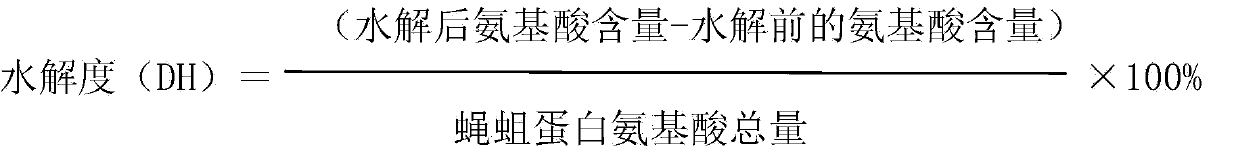

[0015] The detection method of the degree of hydrolysis of the sample in this embodiment is: take 5 mL of the filtrate collected by filtration after inactivating the enzyme and set the volume to 100 mL, and use the ninhydrin method to measure its amino acid content, and the degree of incomp...

Embodiment 2

[0018] Get fresh fly maggot, add and be equivalent to its weight 5 times of water refining, adjust its pH to be 7.0, then add the enzyme composition that is equivalent to fresh fly maggot weight 5% (the weight ratio of compound protease, neutral protease and flavor protease is 1:1.5:1), heat up to 45°C and keep enzymatic hydrolysis for 4 hours, inactivate the enzyme, filter, collect the filtrate (the degree of hydrolysis is 58%, the detection method is the same as in Example 1), concentrate under reduced pressure, and spray dry to obtain the fly maggot protein pink.

[0019] The obtained fly maggot protein powder is added with water to form a solution with a mass concentration of 5%, which has no bitter taste and a little fishy smell.

Embodiment 3

[0021] Get fresh fly maggot, add and be equivalent to its weight 8 times of water refining, adjust its pH to be 6.0, then add the enzyme composition that is equivalent to fresh fly maggot weight 2% (the weight ratio of composite protease, neutral protease and flavor protease is 1:1.5:0.8), heat up to 55°C and heat for 7 hours, inactivate the enzyme, filter, collect the filtrate (the degree of hydrolysis is 62%, the detection method is the same as in Example 1), concentrate under reduced pressure, and spray dry to obtain the fly maggot protein pink.

[0022] The obtained fly maggot protein powder is added with water to form a solution with a mass concentration of 5%, which has no bitter taste and a little fishy smell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com