Waste liquid inactivation device using flash steam

A flash steam and waste liquid technology, applied in the field of waste liquid inactivation devices, can solve the problems of complex control system, poor stability and reliability, and increased recycling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific embodiment the utility model is described further:

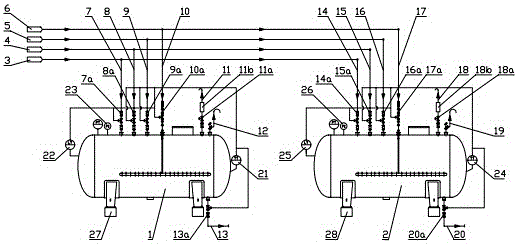

[0018] see figure 1, an embodiment of a waste liquid inactivation device using flash steam, the device includes two independent waste liquid inactivation tanks 1,2. The top of the first waste liquid inactivation tank 1 is respectively provided with a first liquid inlet port 7 communicated with the active waste liquid conveying pipe 3, a first flash steam inlet port 8 communicated with the flash steam conveying pipe 4, and a first flash steam inlet port 8 communicated with the tap water The first water inlet port 9 communicated with the conveying pipe 5, the first industrial steam inlet port 10 communicated with the industrial steam conveying pipe 6, the first exhaust port 11, the first safety valve 12, the first liquid inlet port 7 A first control valve 7a is provided on the first flash steam inlet port 8, a second control valve 8a is provided on the first f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com