A kind of engineering bacteria producing γ-aminobutyric acid and its construction and application

A technology of GABA and GABA transaminase, which is applied in the field of bioengineering, can solve the problems of waste of resources, safety, and reduction of protein expression in the later stage, and achieve the effects of low cost, avoiding decomposition, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

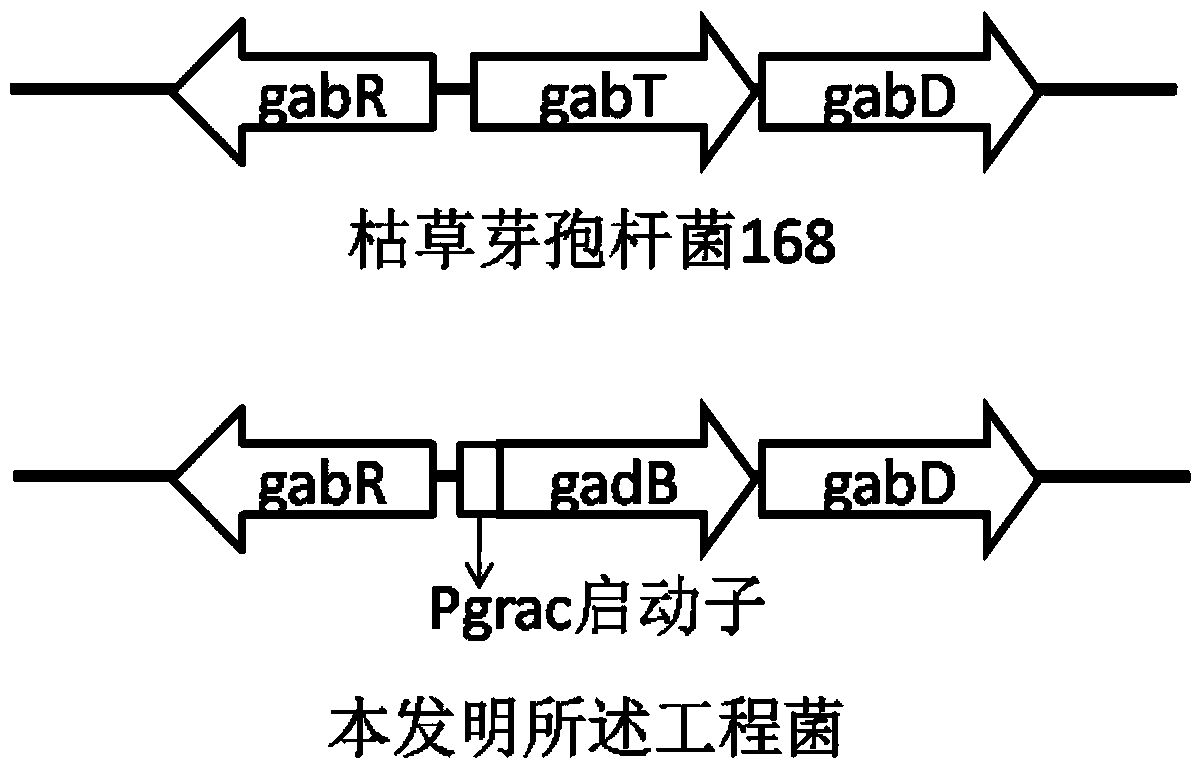

[0038] Example 1 Construction of L-glutamic acid decarboxylase Bacillus subtilis expression vector pHT01-gadB

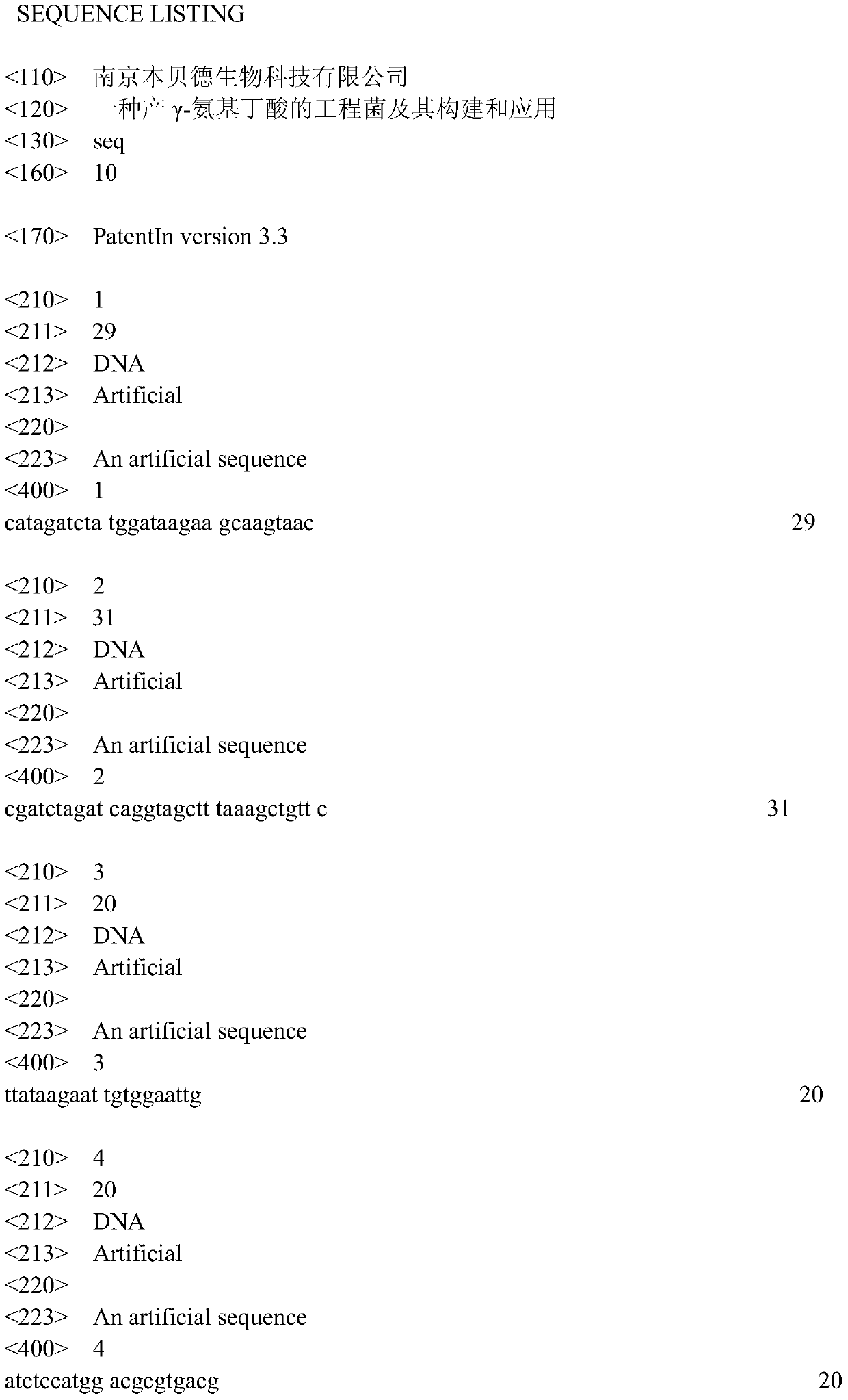

[0039] 1. Design primers according to Escherichia coli gadB gene sequence GenBank No: M84025.1, F-gadB-BglII: CAT AGATCT ATGGATAAGAAGCAAGTAAC (shown in SEQ ID NO.1) and R-gadB-XbaI: CGA TCTAGA TCAGGTAGCTTTAAAGCTGTTC (shown in SEQ ID NO.2) has BglII and XbaI sites added to both ends of the primer;

[0040] 2. Using the total DNA of Escherichia coli DH5α strain as a template, the gadB gene fragment was amplified by PCR with the above primers (shown in SEQ ID NO.1-2). The reaction system included: template 1 μL DNA, 1 μL dNTP (10mmol / L) , 2μmol / L MgCl 2 , 0.5 μmol / L primers, 5 μL 10×PCR buffer, 2.5 U KOD DNA polymerase (TOYOBO company). The PCR reaction conditions include: pre-denaturation at 94°C for 4 min; denaturation at 94°C for 30 s, annealing at 53°C for 30 s, extension at 68°C for 2 min, a total of 30 cycles; 10 min at 72°C. The amplified fragment was subje...

Embodiment 2

[0046] Embodiment 2 Construction of integrated knockout vector

[0047] 1. According to the sequence of Bacillus subtilis 168 bacterial strain genome (Genbank No.NC_000964), design primers: upstream primer F-gabTup-BamHI: GCGGGATCCATGACATTTTGAAAACGGTCGAGG (shown in SEQ ID NO.5) and downstream primer R-01gabTup: GATTATGTTACAATAGCTGGTACCGTGAATATCCCCCCTGTCGGTA (SEQ ID NO .6). Using the genomic DNA of the Bacillus subtilis 168 strain as a template, the upstream 1000 bp fragment of the gabT gene cluster was amplified by PCR, and the PCR conditions were the same as those in Example 1 for amplifying the gabT gene fragment.

[0048] 2. Design primers according to the sequence of the vector pHT01-gadB constructed in Example 1, upstream primer F-gabTup01: TACCGACAGGGGGATATTCACGGTACCAGCTATTGTAACATAATC (shown in SEQ ID NO.7) and downstream primer F-01gabTdn: GTCACGCGTCCATGGAGATCTTTCATTGGAAAGAAAATGGCCG (shown in SEQ ID NO.8) . Using pHT01-gadB as a template, a DNA fragment containing the...

Embodiment 3

[0052] Example 3 Integration of L-glutamic acid decarboxylase into the Bacillus subtilis genome

[0053] 1. Transform the pMAD-ΔgabT::gadB plasmid into Bacillus subtilis 168 strain, and coat with X-gal (5-bromo-4-chloro-3-indole-β-D-galactoside) containing 50 μg / mL and erythromycin plate, cultivated overnight at 30 degrees;

[0054] 2. Pick the blue transformants, culture them overnight at 30°C, spread on a plate containing X-gal and erythromycin, and culture them overnight at 42°C;

[0055] 3. Pick a single blue colony and incubate in LB medium at 42°C for 3 hours, spread on a non-resistant LB plate containing X-gal, and culture overnight at 42°C;

[0056] 4. Pick a single colony with white spots and culture it overnight in erythromycin and non-antibiotic LB medium, select a single colony without erythromycin resistance for colony PCR verification, and select F-gabTup-BamHI (SEQ ID NO. 5) and R-gabTdn-XhoI (shown in SEQ ID NO.10), a colony with a size of 3.7 kb can be ampli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com