A method for treating environmental pollution of farmed chicken manure by using fermentation and brewing method

A technology of chicken manure and fermentation tank, which is applied in the field of environmental pollution control of chicken manure, and can solve problems such as chicken manure waste environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

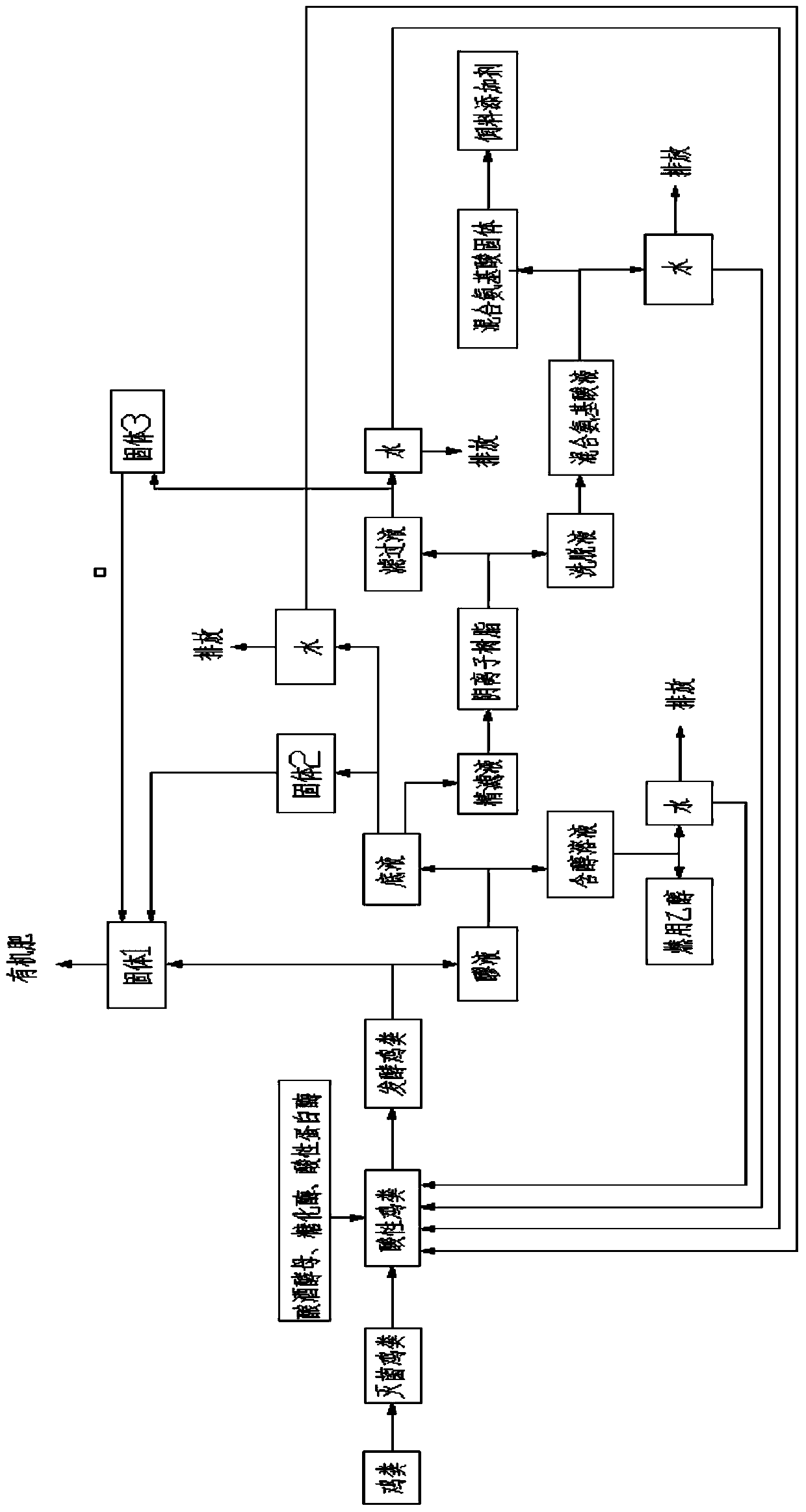

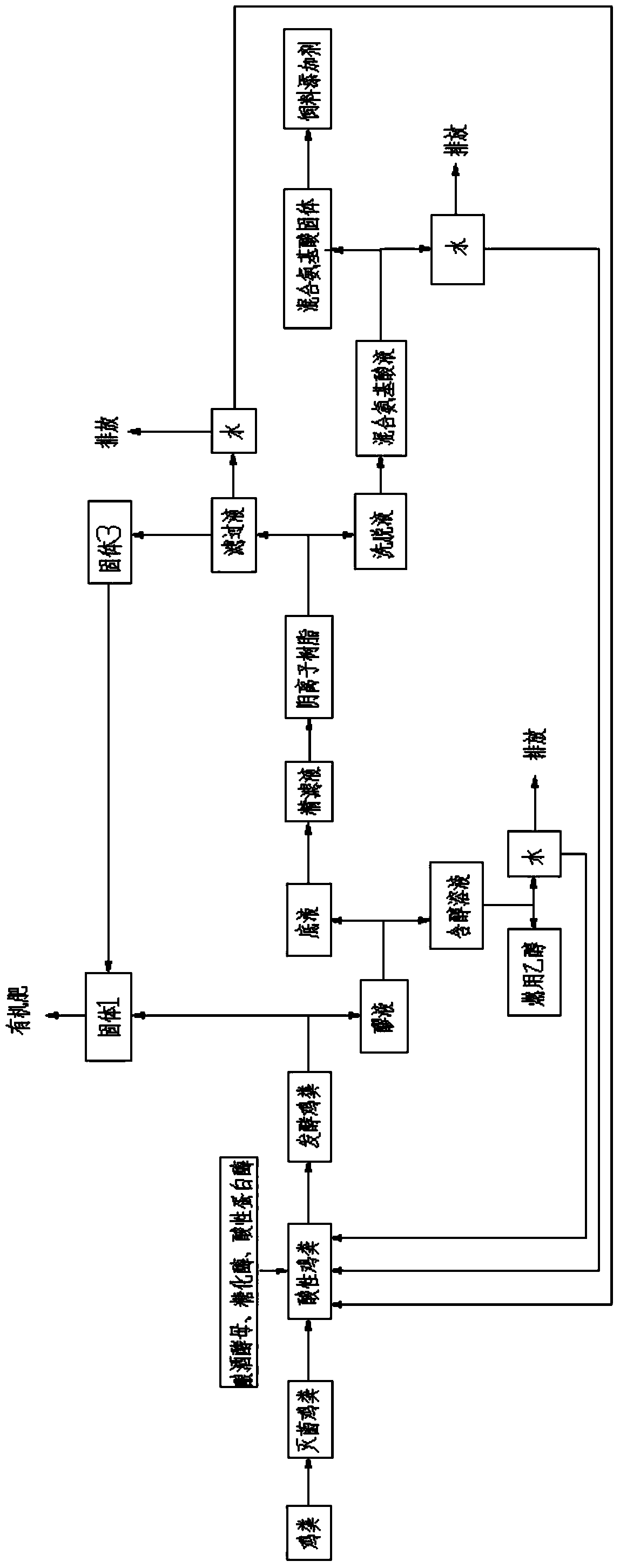

Method used

Image

Examples

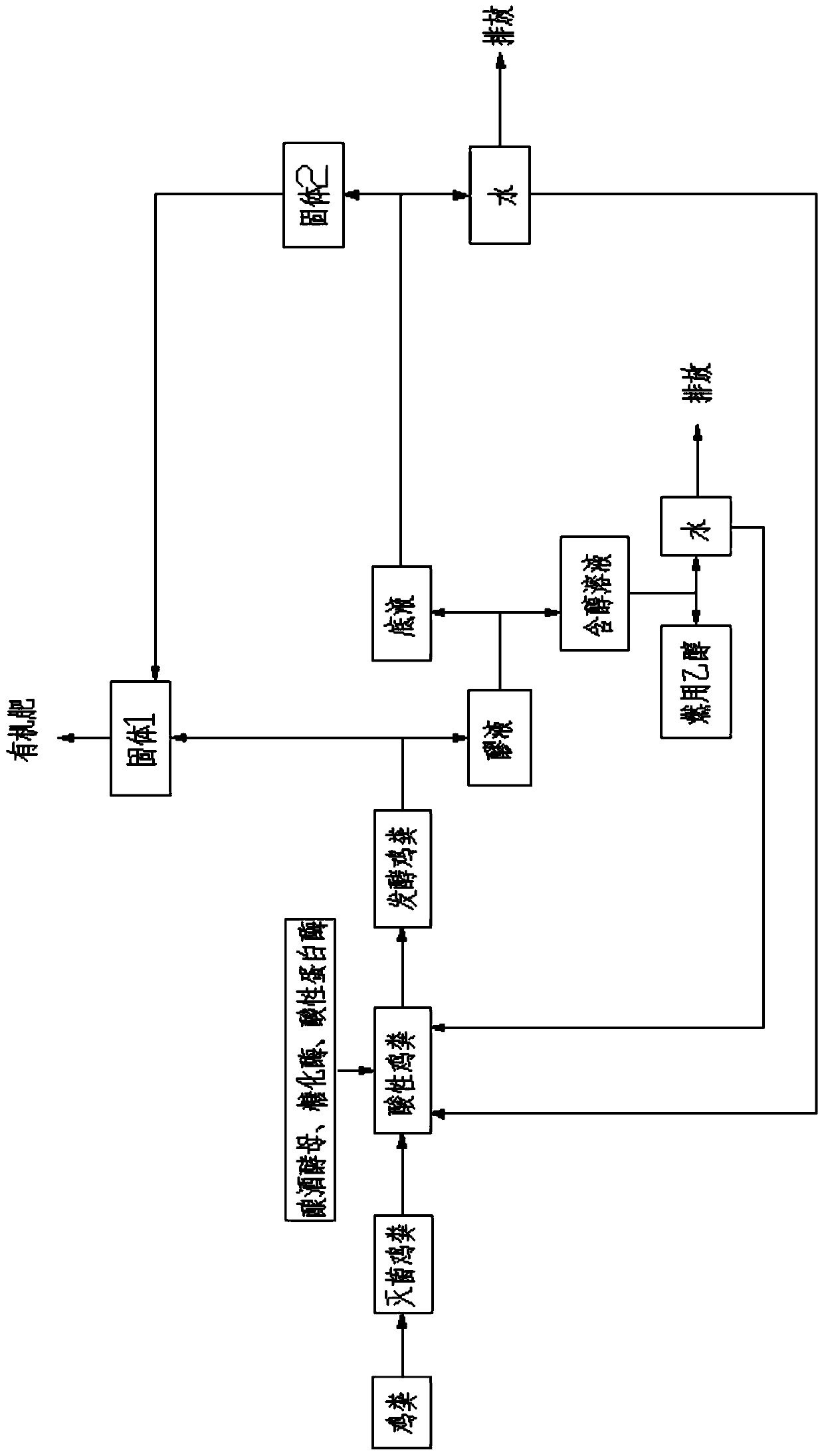

Embodiment 1

[0034] Take 5000Kg of fresh farmed chicken manure, put it in a container at 100-110°C, keep it warm for 60-70min, and the sterilization is completed; measure the solid weight contained in the sterilized chicken manure, and the quantitative standard for the solid content of chicken manure is the solid-liquid ratio: Water 1: solid matter 2.5~3, use H 2 SO 4 or H 3 PO 4 The pH value of the acidification is between 3.5 and 5.0, and the chicken manure is acidified and diluted with an aqueous solution, the solid-liquid ratio is 1:2.5, and then H 2 SO 4 or H 3 PO 4 Adjust the pH value to 3.5, and add 0.5% Saccharomyces cerevisiae, 0.2% glucoamylase and 0.4% acid protease to the diluted material at a temperature of 25°C according to the measured solid weight in the sterilized chicken manure, stir and mix Evenly, put it into a fermentation container, increase the temperature by 5°C based on the temperature when adding Saccharomyces cerevisiae, glucoamylase and acid protease in th...

Embodiment 2

[0036] Take 5000Kg of fresh farmed chicken manure, put it in a container at 100-105°C, keep it warm for 60-65min~, after the sterilization is completed, measure the solid weight contained in the sterilized chicken manure, and use H 2 SO 4 or H 3 PO 4 The pH value of the acidification is between 3.5 and 5.0, and the chicken manure is acidified and diluted with an aqueous solution, the solid-liquid ratio is 1:3.0, and then H 2 SO 4 or H 3 PO 4 Adjust the pH value to 4.0, and add 0.6% Saccharomyces cerevisiae, 0.4% glucoamylase and 0.5% acid protease according to the solid weight contained in the sterilized chicken manure to the diluted material at a temperature of 30°C, stir and mix Evenly, put it into a fermentation container, increase the temperature by 8°C based on the temperature when adding Saccharomyces cerevisiae, glucoamylase and acid protease in the early stage, and keep it warm at 35°C, through the synergistic effect of Saccharomyces cerevisiae, glucoamylase and a...

Embodiment 3

[0038] Take 5000Kg of fresh farmed chicken manure, put it in a heating container and raise the temperature to 100-103°C, keep it warm for 60-65min~, after the sterilization is completed, measure the solid weight contained in the sterilized chicken manure, use H 2 SO 4 or H 3 PO 4 The acidified pH value is between 3.5 and 5.0, and the aqueous solution is acidified and diluted, and the solid-to-liquid ratio is 1:3.5, and then H 2 SO 4 or H 3 PO 4 Adjust the pH value to 4.0, and add 0.6% Saccharomyces cerevisiae, 0.3% glucoamylase and 0.5% acid protease to the diluted material at a temperature of 30°C according to the measured solid weight in the sterilized chicken manure, and stir Mix evenly, put it into a fermentation container, increase the temperature by 5°C based on the temperature when adding Saccharomyces cerevisiae, glucoamylase and acid protease in the early stage, and keep it warm at 35°C, through the synergistic effect of Saccharomyces cerevisiae, glucoamylase and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com