Biodegradable Polyurethane with Gradient Elastic Modulus and Its Fabricated Tissue Engineering Fibrous Scaffold

A technology of elastic modulus and fiber scaffold, which is applied in the field of biodegradable polyurethane with gradient elastic modulus and the tissue engineering fiber scaffold prepared by it, which can solve the differences in cell types, matrix composition and mechanical properties, and the mechanical properties of bionic fibrous annulus Can not achieve mechanical properties, complex microstructure and other problems, to achieve the effect of good biodegradability, excellent mechanical properties, good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

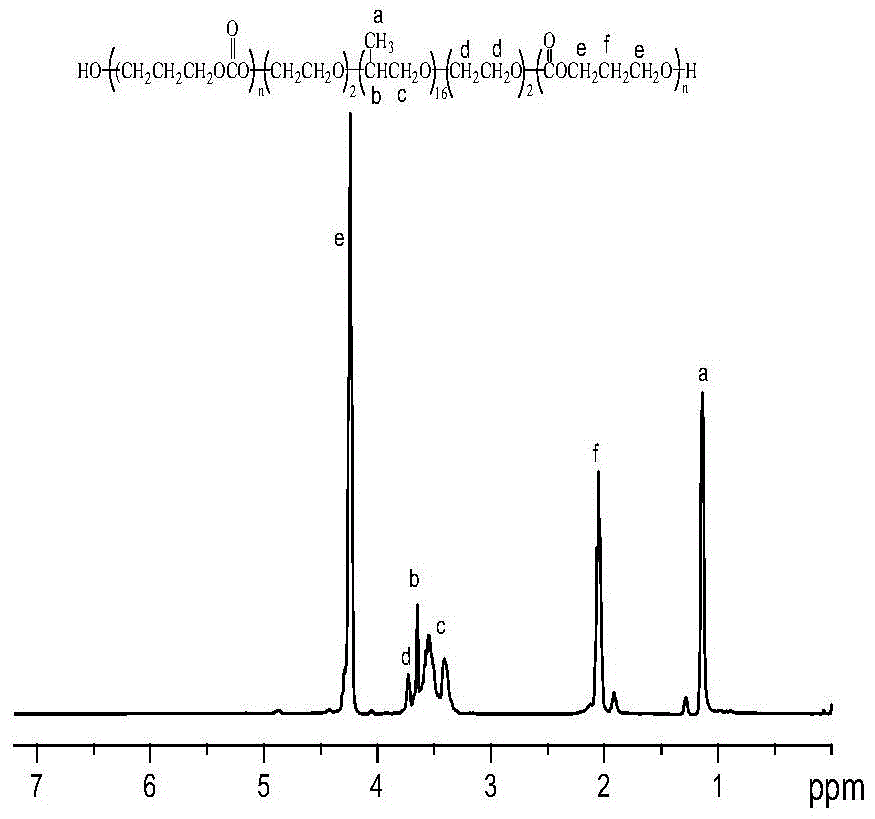

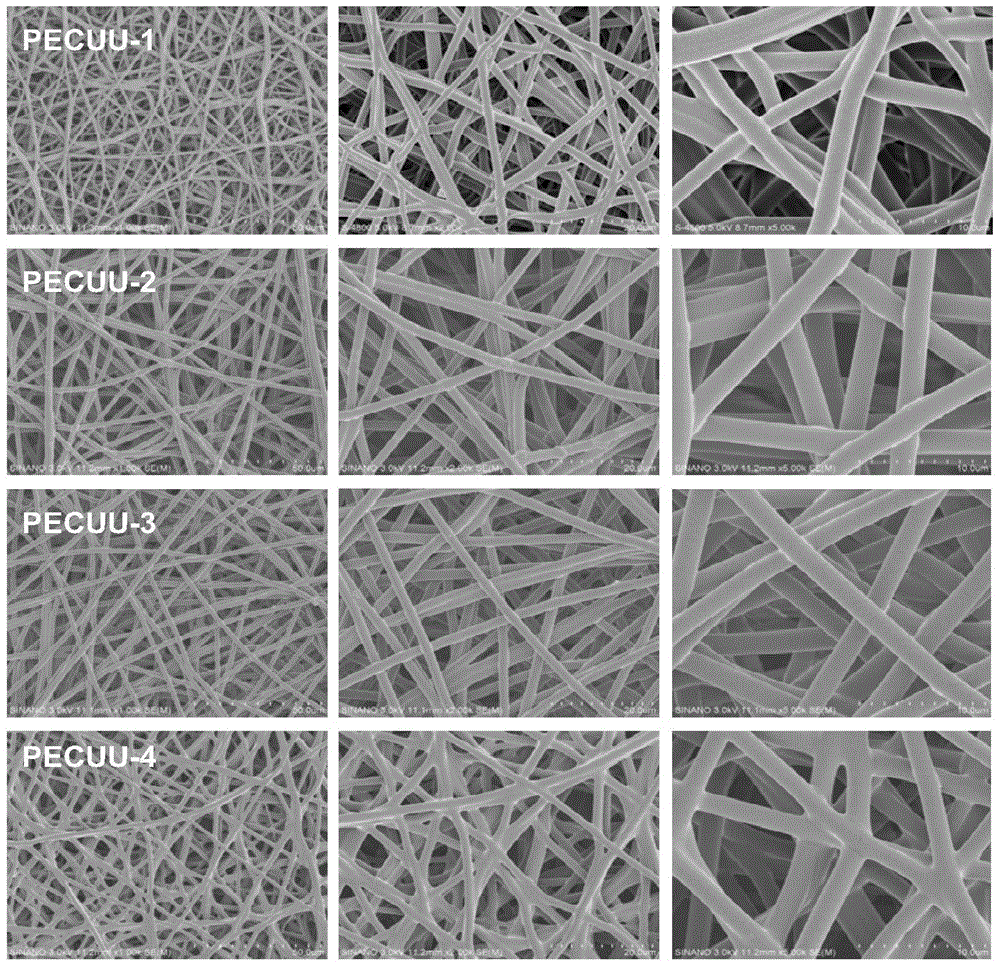

[0037] Embodiment one, elastic modulus is the synthesis of PECUU1 of 13.4MPa

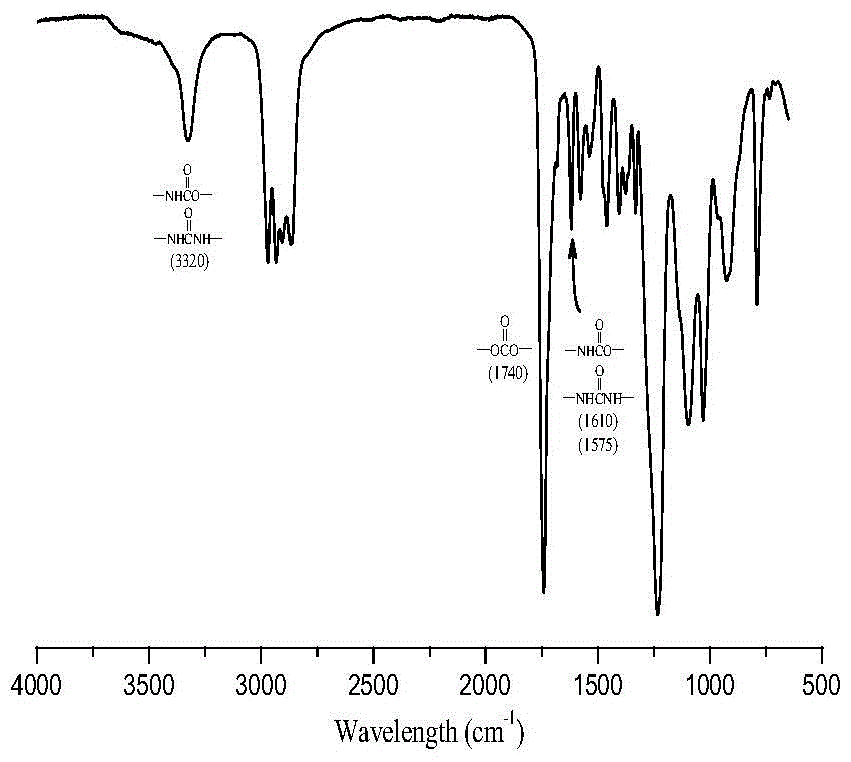

[0038] Under the protection of argon, 10 g of dried PEO-PPO-PEO (1100 Da) was dissolved in toluene (15% by mass fraction), and then a toluene solution of 1,6-diisocyanate (3.05gHDI, mass fraction 15%), after adding 40 mg of the catalyst stannous octoate, react in an oil bath at 75° C. for 4 hours. Then, cool in an ice bath, add dropwise a DMF solution (1% by mass fraction) containing 1.60 g of butanediamine, and keep stirring to keep the solution clear. After reacting overnight, the precipitate was washed twice in a mixed solvent of ethanol / water (v / v, 30 / 70) and dried in vacuo. The FT-IR characterization shows that its structure is polyether polyurethane, and the mechanical tensile test is performed after casting into a film, and its elastic modulus is 13.4MPa.

Embodiment 2

[0039] Embodiment two, elastic modulus is the synthesis of PECUU2 of 6.4MPa

[0040] Under the protection of argon, dissolve 6.5g of dried PEO-PPO-PEO (1100Da) in 85mL of toluene, then add 9.65g of trimethylene carbonate monomer, add 0.48g of stannous octoate catalyst, and polymerize at 110°C React for 24 hours. After cooling down to room temperature, a toluene solution of 1,6-diisocyanate (1.98 g HDI, 15% by mass) was added under stirring conditions, and the temperature was raised to 75° C. for 4 hours. After cooling in an ice bath, a DMF solution (1% by mass fraction) containing 1.04 g of butanediamine was added dropwise, and kept stirring to keep the solution clear. After reacting overnight, the precipitate was washed twice in a mixed solvent of ethanol / water (v / v, 30 / 70) and dried in vacuo. The FT-IR characterization shows that its structure is polycarbonate polyurethane PECUU, and the mechanical tensile test is performed after casting into a film, and its elastic modulu...

Embodiment 3

[0041] Embodiment three, elastic modulus is the synthesis of PECUU3 of 5.1MPa

[0042] Under the protection of argon, dissolve 5.0 g of dried PEO-PPO-PEO (1100 Da) in 100 mL of toluene, then add 14.84 g of trimethylene carbonate monomer, add 0.37 g of stannous octoate catalyst, and polymerize at 110°C React for 24 hours. After cooling to room temperature, a toluene solution of 1,6-diisocyanate (1.53 g HDI, 15% by mass) was added under stirring conditions, and the temperature was raised to 75° C. for 4 hours. After cooling in an ice bath, a DMF solution containing 0.8 g of butanediamine (1% by mass fraction) was added dropwise, and kept stirring to keep the solution clear. After reacting overnight, the precipitate was washed twice in a mixed solvent of ethanol / water (v / v, 30 / 70) and dried in vacuo. The FT-IR characterization shows that its structure is polycarbonate polyurethane PECUU, and the mechanical tensile test is performed after casting into a film, and its elastic mod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com