Device and method for treatment of calcination tail gas

A technology of tail gas treatment and calcination, which is applied in the direction of combination device, separation method, chemical instrument and method, etc., to achieve good economic and social benefits, low overall production cost, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the invention will be further described in detail below in conjunction with specific implementation methods.

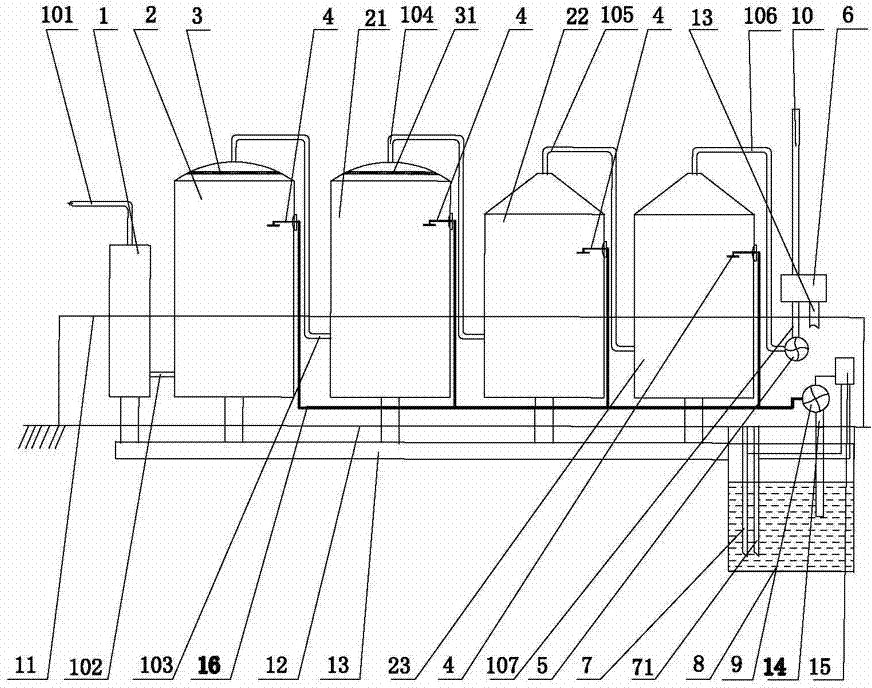

[0023] figure 1 It is a structural representation of the present invention. As shown in the figure, the device of the present invention includes a graphite condenser 1, a first-level spray tower 2, a second-level spray tower 21, a third-level spray tower 22, a fourth-level spray tower 23, a sprayer 4, and an exhaust fan 5 , Water-gas separation chamber 6, etc.

[0024] The high-temperature exhaust gas enters the graphite condenser 1 through the high-temperature exhaust gas inlet pipe 101, and the graphite condenser 1 is connected to the first-stage spray tower 2 through the condensation exhaust pipe 102; the first-stage spray tower 2 is provided with a first defoaming grid 3 , the upper end of the first-level spray tower 2 is provided with a plurality of showers 4 around the upper end, the first-level spray tower 2 is connected to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com