Reinforced medium reaction method and implementation equipment thereof

A medium strengthening and reaction technology, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physicochemical processes, etc., can solve problems such as poor controllability and insufficient control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

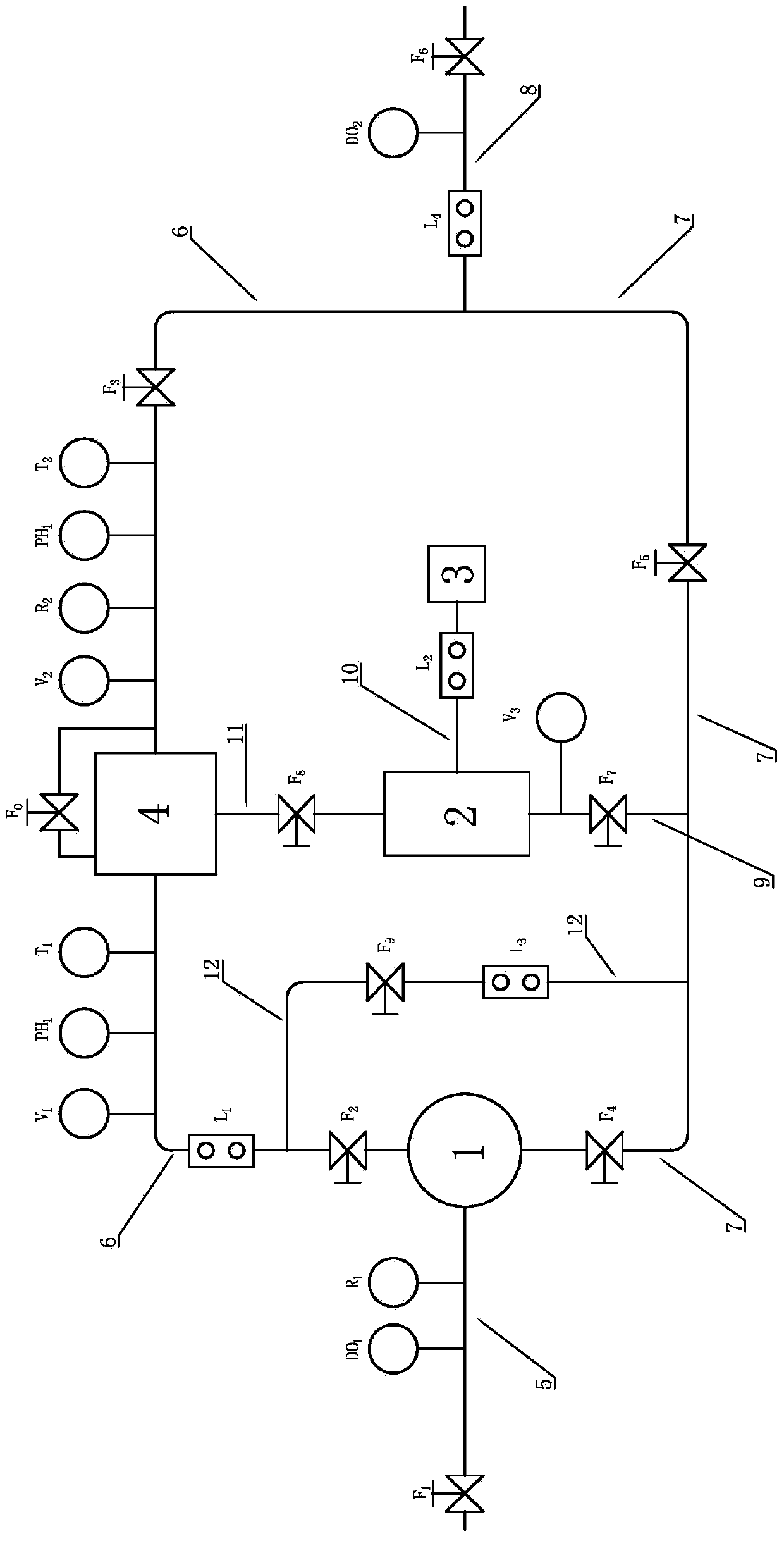

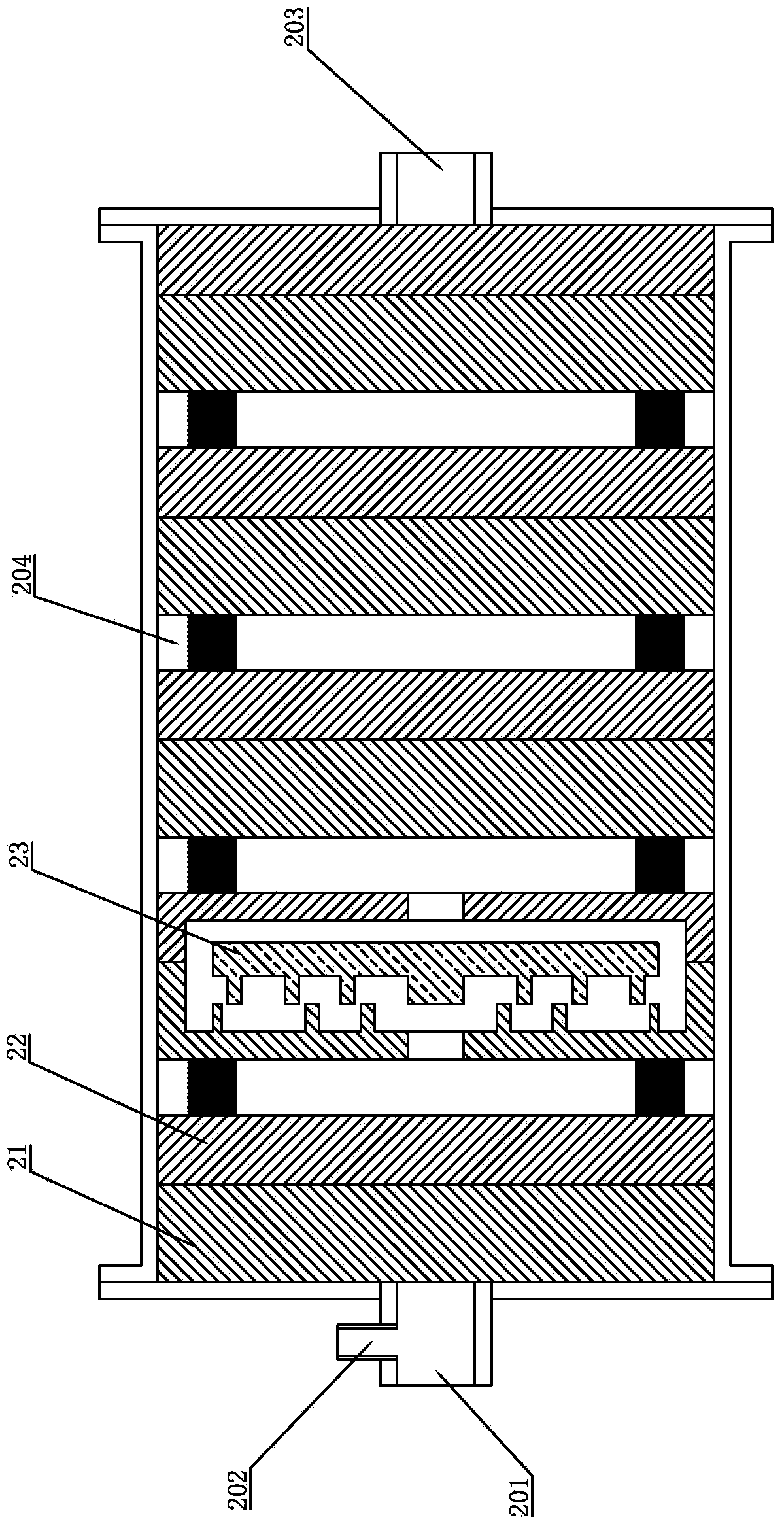

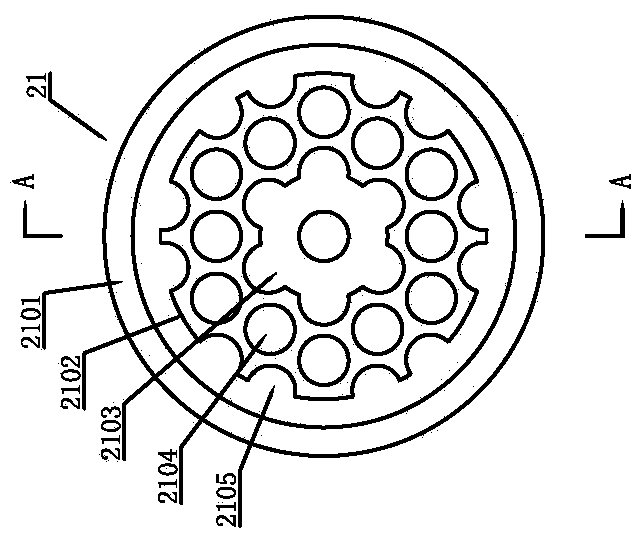

[0148] Quantized liquid is passed in the equipment of the present invention through hydraulic pump 1, dissolved oxygen DO 1 6.12mg / L, redox potential R 1 is 255.6mv; water temperature T 1 17.0°C; pH 1 The value is 6.8-7.0; the hydraulic pump 1 supplies the equipment with a supply pressure of 1.0Mpa, and the inlet pressure V of the cavitation generator 4 1 0.45Mpa; flow meter L 1 For 80 liters per minute, the flow meter L 3 For 20 liters per minute, the flow meter L 2 0.15-0.5 liters per minute, the inlet pressure V of microbubble generator 2 3 0.5-0.6Mpa, the outlet pressure V of cavitation generator 4 2 0.02Mpa; Oxidation-reduction potential R 2 282.5-382.5mv; water temperature T 1 72.0-77.0 ℃, water temperature difference T 2 -T 1 =55°C, pH 1 The value is 2.0-5.8, after the equipment operates normally, from the two-way passage valve F 5 Take a sample and collect the product containing nano-microbubbles, with a density of 1.2-1.4 billion microbubbles per millilite...

Embodiment 2

[0187] Liquid modification example when the liquid medium is pure water

[0188] Deionized water (equivalent to twice distilled water) with a pH value of 6.5-7.2 and a resistance value of 120 MΩ enters the system of the present invention through the hydraulic pump 1 . Dissolved oxygen (inolab Oxi Level2 dissolved oxygen meter, German WTW company) DO 1 It is 6.12mg / L; Oxidation-reduction potential (IIANNA211 acidity meter, Italy Hana company) R 1 is 255.6mv; water temperature T 1 is 17.0°C; pH1 is 6.8; the hydraulic pump 1 supplies the system with a system supply pressure of 1.0Mpa; the inlet pressure V of the cavitation generator 4 1 0.45Mpa (two-way passage valve F 0 is the best state fine-tuning valve for cavitation generator 4); flow meter (LRT-1, Shanghai Heji Automation Instrument Co., Ltd.) L 1 80 liters per minute; flow meter L 3 It is 20 liters per minute; the medium of the gas supply device 3 is air, and the flow meter L 2 It is 0.15 liters per minute; the micro...

Embodiment 3

[0190] Oxygen-enriched water system

[0191] Deionized water (equivalent to twice distilled water) with a pH value of 6.5-7.2 and a resistance value of 120 MΩ enters the system of the present invention through the hydraulic pump 1 . DO 1 6.12mg / L; redox potential R 1 is 255.6mv; water temperature T 1 17.0°C; pH 1 The value is 6.8; the hydraulic pump 1 supplies the system with a system supply pressure of 1.0Mpa; the inlet pressure V of the cavitation generator 4 1 0.45Mpa (two-way passage valve F 0 is the best condition trimmer valve for cavitation generator 4); flow meter L 1 80 liters per minute; flow meter L 3 It is 20 liters per minute; the medium of the gas supply device 3 is oxygen O2, and the flow meter L 2 is 0.20 liters per minute; the microbubble generator assembly 2 is eight groups; the inlet pressure V of the microbubble generator assembly 2 3 It is 0.6Mpa. After the device of the present invention operates normally, from the two-way passage valve F 5 Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com