Carbonyl sulfide hydrolysis catalyst, preparation method and application thereof

A technology of hydrolysis catalyst and carbonyl sulfide, which is applied in the field of carbonyl sulfide hydrolysis catalyst and its preparation, which can solve the problems of short catalyst life, difficulty in industrial promotion, and low treatment concentration, and achieve uniform distribution of active components, low requirements for preparation conditions, and preparation The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Al(NO 3 ) 3 9H 2 0, Ce (NO 3 ) 3 ·6H 2 0 and Mg (NO 3 ) 2 ·6H 2 0 dissolved in deionized water at a molar ratio of Mg 2+ / (Al 3+ 、Ce 3+ ) 1.3:1, Al 3+ with Ce 3+ Molar ratio 14:1, made into solution A;

[0027] (2) Combine NaOH and Na 2 CO 3 Dissolved in deionized water, NaOH and Na 2 CO 3 The molar ratio of is 1.2:1, is dubbed solution B;

[0028] (3) Add solution B dropwise to solution A at a rate of 0.5ml / s, adjust the pH to 7.5, continue to stir to obtain a suspension, and then place the suspension in water at a temperature of 140°C for 10 hours;

[0029] (4) Filter and wash the precipitate in step (3) until the filtrate pH=7, and dry the obtained filter cake at 60°C for 8 hours;

[0030] (5) Calcinate the product obtained in step (4) for 3 hours under air condition at a temperature of 200°C, press into tablets and sieve, and take 40-60 meshes to obtain the catalyst.

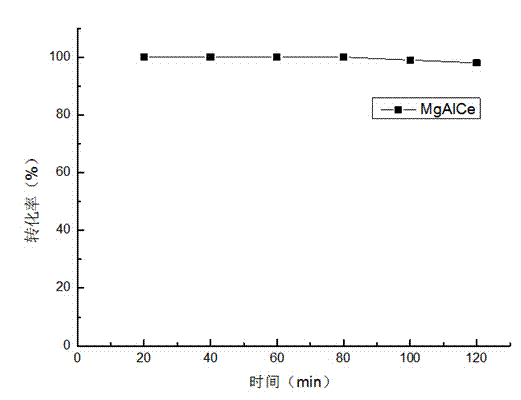

[0031] When using the catalyst prepared in this example to remove COS, the ...

Embodiment 2

[0033] (1) Al(NO 3 ) 3 9H 2 0, Ce (NO 3 ) 3 ·6H 2 0 and Mg (NO 3 ) 2 ·6H 2 0 dissolved in deionized water at a molar ratio of Mg 2+ / (Al 3+ 、Ce 3+ ) 1.7:1, Al 3+ with Ce 3+ Molar ratio 18:1, made into solution A;

[0034] (2) Combine NaOH and Na 2 CO 3 Dissolved in deionized water, NaOH and Na 2 CO 3 The molar ratio of is 2:1, is dubbed solution B;

[0035] (3) Add solution B dropwise to solution A at a rate of 1ml / s, adjust the pH to 8, continue to stir to obtain a suspension, and then place the suspension in water at a temperature of 140°C for 12 hours;

[0036] (4) Filter and wash the precipitate in step (3) until the filtrate pH=7, and dry the obtained filter cake at 100°C for 12 hours;

[0037] (5) Calcinate the product obtained in step (4) for 3 hours under air condition at a temperature of 500°C, press into tablets and sieve, and take 40-60 meshes to obtain the catalyst.

[0038]When using the catalyst prepared in this example to remove COS, the catal...

Embodiment 3

[0040] (1) Al(NO 3 ) 3 9H 2 0, Ce (NO 3 ) 3 ·6H 2 0 and Mg (NO 3 ) 2 ·6H 2 0 dissolved in deionized water at a molar ratio of Mg 2+ / (Al 3+ 、Ce 3+ ) 1.5:1, Al 3+ with Ce 3+ Molar ratio 16:1, made into solution A;

[0041] (2) Combine NaOH and Na 2 CO 3 Dissolved in deionized water, NaOH and Na 2 CO 3 The molar ratio of is 1.5:1, is dubbed solution B;

[0042] (3) Add solution B dropwise to solution A at a rate of 0.8ml / s, adjust the pH to 7.6, continue to stir to obtain a suspension, and then place the suspension in water at a temperature of 140°C for 11 hours;

[0043] (4) Filter and wash the precipitate in step (3) until the filtrate pH=7, and dry the obtained filter cake at 70°C for 9 hours;

[0044] (5) Calcinate the product obtained in step (4) for 3 hours under air condition at a temperature of 300°C, press into tablets and sieve, and take 40-60 meshes to obtain the catalyst.

[0045] When using the catalyst prepared in this example to remove COS, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com