Automatic brake device and automatic brake method of automobile capstan

An automatic brake and winch technology, applied in the direction of hoisting device, etc., can solve the problems of high operation failure, complex structure, short life, etc., and achieve the effect of high braking reliability, large cone surface area and small vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

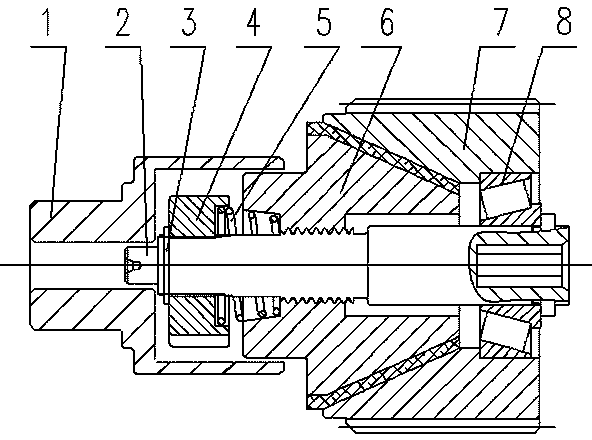

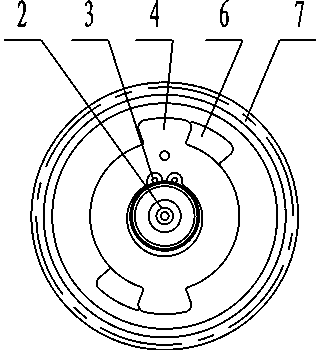

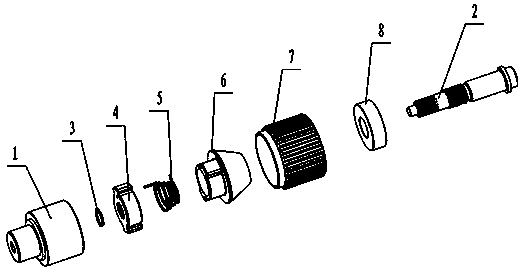

[0018] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0019] The vehicle winch automatic brake device of the present invention mainly consists of a shaft cover 1, a brake shaft 2, a circlip 3 for the shaft, a lug plate 4, a torsion spring 5, a cone brake part 6, a brake cone sleeve 7, a single-row conical roller The sub-bearing 8 is composed of the brake taper sleeve 7 and the spline engagement of the outer cable disc. The brake shaft 2, the lug disc 4, the torsion spring 5, and the cone brake parts 6 form a screw clutch mechanism, and the brake shaft 2 drives the screw clutch mechanism. The clutch mechanism realizes separation. One end of the brake shaft 2 extends into the shaft cover 1, and the brake shaft 2 extends into the screw clutch mechanism provided on one end of the shaft cover 1. The screw clutch mechanism includes a cone brake part 6, a torsion spring 5 and lugs. The disc 4 and the cone brake part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com