Bamboo-fibril-reinforced modified vegetable oil-base unsaturated polyester composite material

A polyester composite material and modified vegetable oil technology, which is applied in the field of natural plant fiber reinforced resin composite materials, can solve the problems of air pollution, large amount of styrene, etc., and achieve the effect of high impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

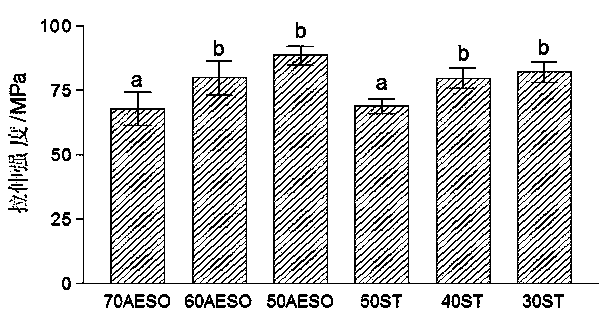

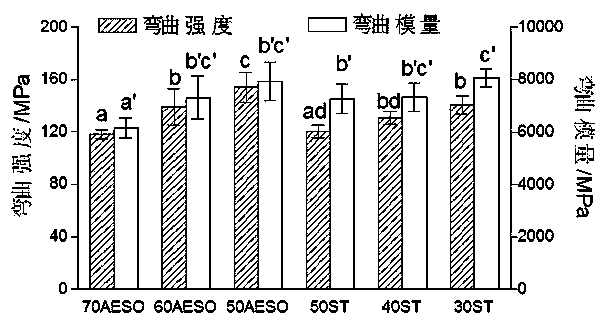

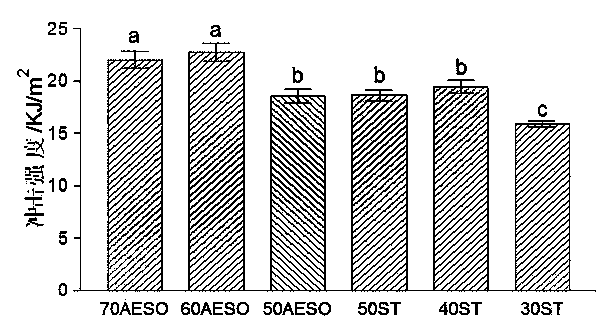

[0016] Raw materials: bamboo fiber (average length 22.81mm, average width 150μm) provided by Fujian Haibosi Chemical Technology Co., Ltd.; solid unsaturated polyester (UPE) resin is phthalic acid type unsaturated polyester resin without styrene (Model: PG-ISO Plastic 2, containing 4000ppm monomethyl ether-hydroquinone polymerization inhibitor), purchased from Ashland Chemical Company of the United States; Acrylated epoxy soybean oil (AESO) purchased from Sigma-Aldrich Company of the United States ; The initiator was tert-butyl peroxybenzoate (TBPB), which was purchased from Sigma-Aldrich, USA.

[0017] Bamboo fiber reinforced modified vegetable oil-based UPE composite material:

[0018] The solid UPE resin, modified vegetable oil and initiator are mixed according to a certain mass ratio to obtain a modified vegetable oil-based UPE resin mixed solution. The mixed solution of bamboo fiber and modified vegetable oil-based UPE resin is formed by hot pressing to obtain bamboo fibe...

Embodiment 2

[0022] Raw materials: bamboo fiber (average length 22.81mm, average width 150μm) provided by Fujian Haibosi Chemical Technology Co., Ltd.; solid unsaturated polyester (UPE) resin is phthalic acid type unsaturated polyester resin without styrene (Model: PG-ISO Plastic 2, containing 4000ppm monomethyl ether-hydroquinone polymerization inhibitor), purchased from Ashland Chemical Company of the United States; Acrylated epoxy soybean oil (AESO) purchased from Sigma-Aldrich Company of the United States ; The initiator was tert-butyl peroxybenzoate (TBPB), which was purchased from Sigma-Aldrich, USA.

[0023] Bamboo fiber reinforced modified vegetable oil-based UPE composite material:

[0024] The solid UPE resin, modified vegetable oil and initiator are mixed according to a certain mass ratio to obtain a modified vegetable oil-based UPE resin mixed solution. The mixed solution of bamboo fiber and modified vegetable oil-based UPE resin is formed by hot pressing to obtain bamboo fibe...

Embodiment 3

[0028] Raw material: bamboo fiber (average length 22.81mm, average width 150μm) provided by Fujian Haibosi Chemical Technology Co., Ltd.; solid unsaturated polyester (UPE) resin is phthalic acid type unsaturated polyester resin (model: PG- ISO Plastic 2, containing 4000ppm monomethyl ether-hydroquinone polymerization inhibitor), was purchased from Ashland Chemical Company, U.S.; Acrylated epoxy soybean oil (AESO) was purchased from Sigma-Aldrich Company, U.S.; Tert-butyl benzoate (TBPB) was purchased from Sigma-Aldrich, USA.

[0029] Bamboo fiber reinforced modified vegetable oil-based UPE composite material:

[0030] The solid UPE resin, modified vegetable oil and initiator are mixed according to a certain mass ratio to obtain a modified vegetable oil-based UPE resin mixed solution. The mixed solution of bamboo fiber and modified vegetable oil-based UPE resin is formed by hot pressing to obtain bamboo fiber-reinforced modified vegetable oil-based UPE resin composite material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com