A kind of environment-friendly wear-resistant epdm material and preparation method thereof

An environmentally friendly and rubber-based technology, applied in the field of rubber materials, can solve the problems of complex preparation methods and non-latex rubber preparation technology not mentioned, and achieve the effects of excellent wear resistance, increased strength, and good tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

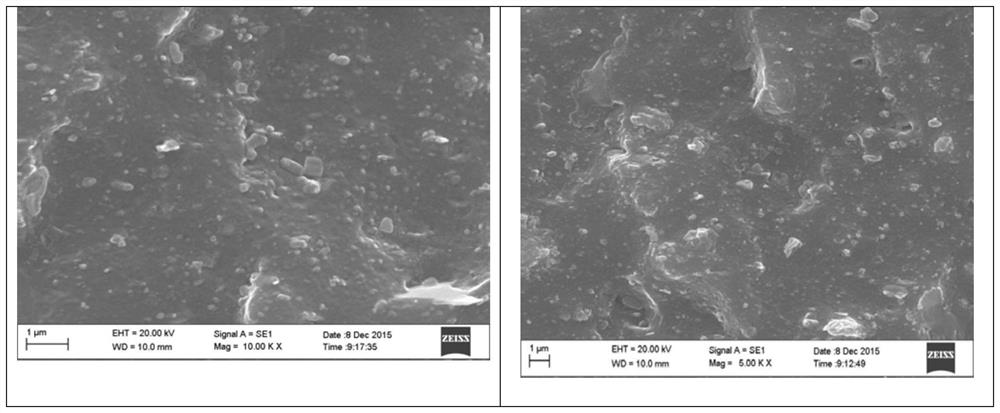

Image

Examples

Embodiment 1

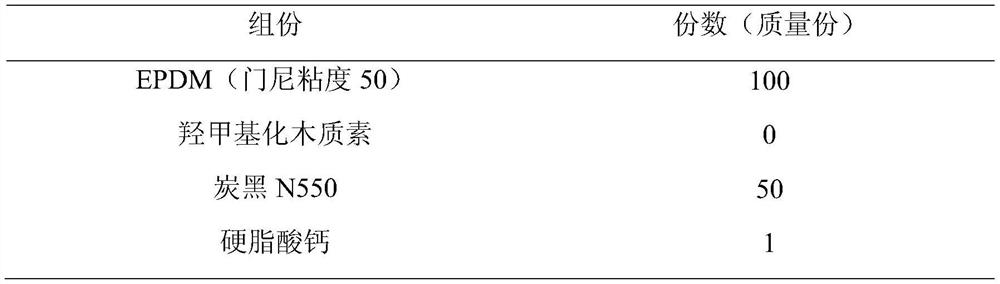

[0036] An environment-friendly and wear-resistant EPDM material in this embodiment, the mixing ratio is shown in Table 2.

[0037] Table 2

[0038]

[0039]

[0040] The mixing process of the environmental protection wear-resistant EPDM material of this embodiment:

[0041] A. One-stage mixing: adjust the roll temperature of the open mill to room temperature, circulate the cooling roll temperature, adjust the roll speed ratio to 1:1.6, and then mix EPDM rubber, calcium stearate, zinc oxide, and TAIC evenly on the open mill ;

[0042] B. Two-stage mixing: set the rotor speed of the internal mixer to 20rpm, and the pressure of the pressure bar to 0.5MPa, put a section of mixed rubber into the internal mixer, mix for 3min, and divide the hydroxymethylated wood into four times Put into the internal mixer and mix for 5 minutes each time, adjust the temperature of the internal mixer to 60°C, add modifier and mix for 30 minutes;

[0043] C. Three-stage mixing: set the intern...

Embodiment 2

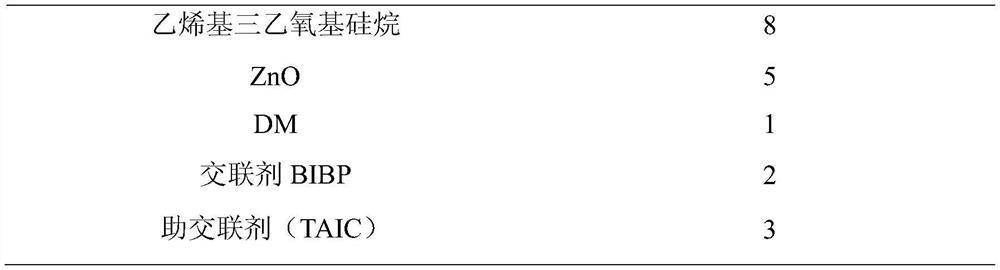

[0046] An environment-friendly and wear-resistant EPDM material in this embodiment, the mixing ratio is shown in Table 3.

[0047] table 3

[0048]

[0049]

[0050] The mixing process of the environmental protection wear-resistant EPDM material of this embodiment:

[0051] A. One-stage mixing: adjust the roll temperature of the open mill to room temperature, circulate the cooling roll temperature, adjust the roll speed ratio to 1:1.6, and then mix EPDM rubber, calcium stearate, zinc oxide, and TAIC evenly on the open mill ;

[0052] B. Two-stage mixing: set the rotor speed of the internal mixer to 30rpm, and the pressure of the pressure rod to 0.5MPa, put a section of the mixed rubber into the internal mixer, and mix for 5min, divide the hydroxymethylated wood into four times Put into the internal mixer and mix for 7 minutes each time, adjust the temperature of the internal mixer to 70°C, add modifier and mix for 30 minutes;

[0053] C. Three-stage mixing: set the in...

Embodiment 3

[0056] An environmentally friendly and wear-resistant EPDM material in this embodiment, the mixing ratio is shown in Table 4.

[0057] Table 4

[0058]

[0059] The mixing process of the environmental protection wear-resistant EPDM material of this embodiment:

[0060]A. One-stage mixing: adjust the roll temperature of the open mill to room temperature, circulate the cooling roll temperature, adjust the roll speed ratio to 1:1.6, and then mix EPDM rubber, calcium stearate, zinc oxide, and TAIC evenly on the open mill ;

[0061] B. Two-stage mixing: set the rotor speed of the internal mixer to 30rpm, and the pressure of the pressure rod to 0.5MPa, put a section of the mixed rubber into the internal mixer, and mix for 5min, divide the hydroxymethylated wood into four times Put into the internal mixer and mix for 7 minutes each time, adjust the temperature of the internal mixer to 80°C, add modifier and mix for 30 minutes;

[0062] C. Three-stage mixing: set the internal mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com