Plant fiber reinforced composite material based on methacrylate crosslinked soybean oil-based resin and preparation method thereof

A soybean oil-based resin, methacrylate technology, applied in the direction of coating, can solve the problems of poor heat resistance, high viscosity, low cross-linking degree of epoxy soybean oil acrylate, etc., and achieve the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

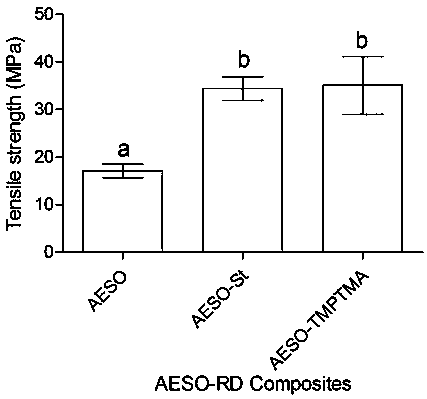

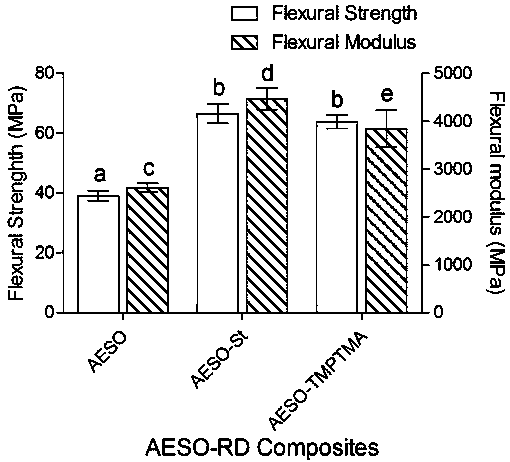

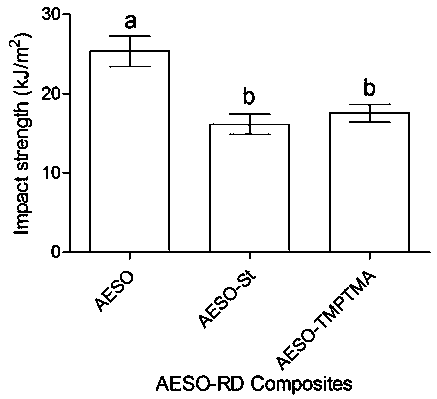

[0022] Vegetable Fiber / Methacrylate Soybean Oil-Based Resin Composites:

[0023] The preparation process of soybean oil-based resin is as follows: soybean oil derivatives (70g) and cross-linking agent (30g) are placed in a round bottom flask, and after stirring with a magnetic stirrer at room temperature for 20min, the soybean oil-based resin mixture is obtained; The soybean oil derivative is AESO; the cross-linking agent is TMPTMA; the initiator is TBPB.

[0024] Composite material preparation method: Weigh 76.4g of soybean oil-based resin mixture and 1.6g of TBPB, mix and stir for 1min with a glass rod. Take the dried plant fibers out of the oven, wrap them in plastic airtight bags, and when they are cooled to room temperature, stack 5-9 pieces of fiber mats (76.4g) in the orthogonal direction to form a fiber slab. Soybean oil-based resin and additives are evenly coated on both surfaces of the fiber slab, then moved to a steel mold and preheated for 5 minutes at 70°C and a ...

Embodiment 2

[0037] Vegetable Fiber / Methacrylate Soybean Oil-Based Resin Composites:

[0038] The preparation process of soybean oil-based resin is as follows: soybean oil derivatives (60g) and cross-linking agent (40g) are placed in a round bottom flask, and after stirring with a magnetic stirrer at room temperature for 30min, the soybean oil-based resin mixture is obtained; The soybean oil derivative is AESO; the cross-linking agent is TMPTMA; the initiator is TBPB.

[0039] Composite material preparation method: Weigh 80g of soybean oil-based resin mixture and 2.5g of TBPB, mix and stir for 1min with a glass rod. Take the dried plant fiber out of the oven, wrap it in a plastic airtight bag, and when it cools down to room temperature, stack 5-9 pieces of fiber mats (90g) in the orthogonal direction to form a fiber slab. Soybean oil-based resin and additives are evenly coated on both surfaces of the fiber slab, then moved to a steel mold and preheated at 70°C and 7MPa pressure for 4 minu...

Embodiment 3

[0041] Vegetable Fiber / Methacrylate Soybean Oil-Based Resin Composites:

[0042] The preparation process of soybean oil-based resin is as follows: soybean oil derivatives (80g) and cross-linking agent (20g) are placed in a round bottom flask, and after stirring with a magnetic stirrer at room temperature for 30min, the soybean oil-based resin mixture is obtained; The soybean oil derivative is AESO; the cross-linking agent is TMPTMA; the initiator is TBPB.

[0043] Composite material preparation method: Weigh 100g of soybean oil-based resin mixture and 3g of TBPB, mix and stir for 1min with a glass rod. Take the dried plant fiber out of the oven, wrap it in a plastic sealed bag, and when it cools down to room temperature, stack and arrange 5-9 pieces of fiber mats (80g) in the orthogonal direction to form a fiber slab. Soybean oil-based resin and additives are evenly coated on both surfaces of the fiber slab, then moved to a steel mold and preheated for 5 minutes at 70°C and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com