Black solar heat reflective cooling coating and preparation method thereof

A solar heat and black technology, applied in the direction of reflection/signal paint, coating, etc., can solve the problems of complex formula of cooling paint, short outdoor service life, poor anti-aging performance, etc., to improve solar heat reflectivity and cooling effect, Excellent light stability and weather resistance, good effect of anti-aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A black solar heat reflection cooling paint, characterized in that: its components and weight ratio are:

[0043] Acrylic emulsion 40 parts;

[0044] 1 part black functional pigment;

[0045] 0.1 part of decolorizing pigment;

[0046] Body pigment 10 parts;

[0047] 1 part of auxiliary agent;

[0048] 1 part of water;

[0049] The components and parts by weight ratio of the extender pigment are:

[0050]5 parts of talcum powder;

[0051] 1 part of heavy calcium carbonate;

[0053] 3 parts of silicon dioxide;

[0054] Components and parts by weight of the auxiliary agent are:

[0055] Dispersant 0.1 part;

[0056] Wetting agent 0.1 part;

[0057] 0.3 part of defoamer;

[0058] Leveling agent 0.3 parts;

[0059] 0.2 parts of film-forming aids.

[0060]

Embodiment 2

[0062] A black solar heat reflection cooling paint, characterized in that: its components and weight ratio are:

[0063] Acrylic emulsion 50 parts;

[0064] 5 parts of black functional pigment;

[0065] 1 part of decolorizing pigment;

[0066] Body pigment 30 parts;

[0067] 5 parts of auxiliary agent;

[0068] 10 parts of water;

[0069] The components and parts by weight ratio of the extender pigment are:

[0070] 15 parts of talcum powder;

[0071] 2 parts of heavy calcium carbonate;

[0072] 3 parts of barium sulfate;

[0073] 10 parts of silicon dioxide;

[0074] Components and parts by weight of the auxiliary agent are:

[0075] Dispersant 0.9 parts;

[0076] 1.1 parts of wetting agent;

[0077] 1.2 parts of defoamer;

[0078] Leveling agent 0.8 parts

[0079] 1 part of film-forming aid.

[0080]

Embodiment 3

[0082] A kind of black solar heat reflection cooling paint is characterized in that: it is prepared from the following raw materials according to weight percentage:

[0083] Acrylic emulsion 45 parts;

[0084] 3 parts of black functional pigment;

[0085] 0.5 part of decolorizing pigment;

[0086] Body pigment 20 parts;

[0087] 3 parts of auxiliary agent;

[0088] 5 parts of water.

[0089] The components and parts by weight ratio of the extender pigment are:

[0090] 11 parts of talcum powder;

[0091] 1.5 parts of heavy calcium carbonate;

[0092] 1.5 parts of barium sulfate;

[0093] 6 parts of silicon dioxide;

[0094] Components and parts by weight of the auxiliary agent are:

[0095] 0.5 parts of dispersant;

[0096] 0.7 parts of wetting agent;

[0097] 0.6 part of defoamer;

[0098] Leveling agent 0.7 parts;

[0099] 0.5 parts of film-forming aids.

[0100] Among them, in the three embodiments, the proportions of the various additive components can be fle...

PUM

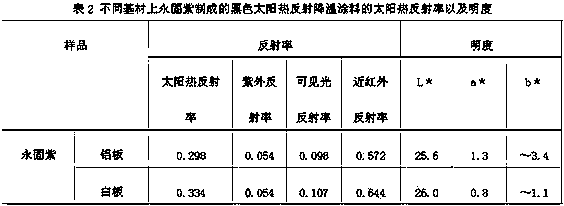

| Property | Measurement | Unit |

|---|---|---|

| minimum film forming temperature | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com