Method for separating milk fat based on melting layer crystallizing technology

A technology of milk fat and molten layer, applied in the direction of producing fat, fat oil/fat separation, etc., can solve the problems of difficult solid-liquid separation operation, prolonged oil production cycle, difficult temperature control, etc., to improve separation efficiency and avoid solid-liquid separation. Centrifugation and filtration operation, the effect of short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for separating milk fat based on melting layer crystallization technology, including the following steps:

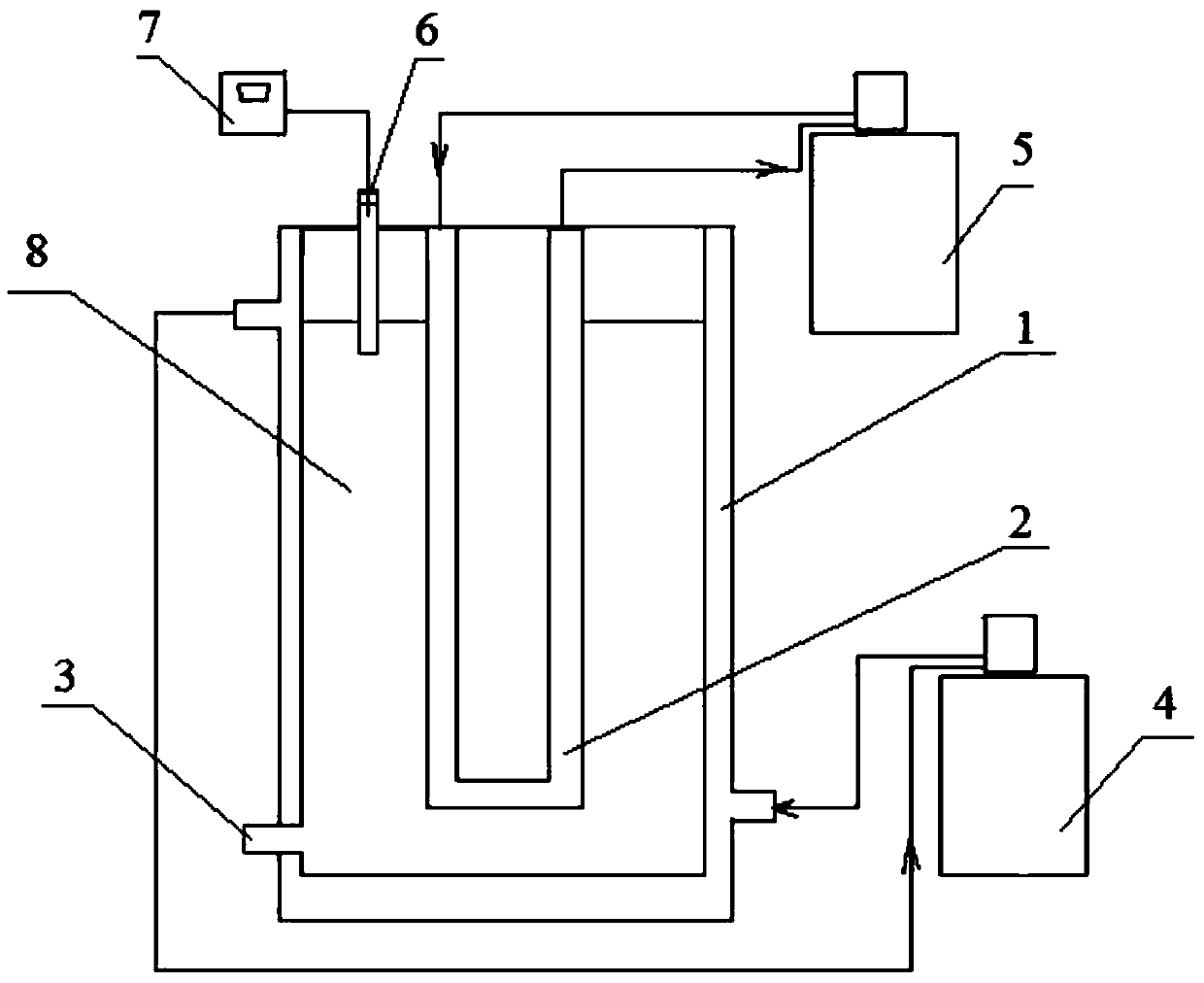

[0031] (1) Prepare a crystallization device with a double jacket;

[0032] (2) Weigh 250g of anhydrous milk fat, raise the temperature to 60℃ with stirring, keep the temperature at constant temperature for 40 minutes, and put it into a crystallization tank with a double-jacketed crystallization device (the volume of the crystallization tank is 500ML), and control the outer layer The temperature of the circulating water in the jacket is 42°C, and the temperature of the inner jacket is reduced to 34°C within 45 minutes and maintained for 30 minutes;

[0033] (3) Decrease the temperature of the inner jacket to 26°C within 90 minutes, and maintain it at 26°C for 120 minutes, so that the outer surface of the inner jacket will grow a crystal layer, and the mother liquor will be discharged from the mother liquor outlet. The temperature of the jacket is increased to 37...

Embodiment 2

[0035] A method for separating milk fat based on melting layer crystallization technology, including the following steps:

[0036] (1) Prepare a crystallization device with a double jacket;

[0037] (2) Weigh 250g of anhydrous milk fat, raise the temperature to 60°C under stirring, keep it at constant temperature for 60 minutes, and put it into a crystallization tank with a double-jacketed crystallization device (the volume of the crystallization tank is 500ML), and control the outer layer The temperature of the circulating water in the jacket is 40°C, and the temperature of the inner jacket is reduced to 33°C within 30 minutes and maintained for 30 minutes;

[0038] (3) Reduce the temperature of the inner jacket to 24°C within 60 minutes, and maintain it at 24°C for 120 minutes, so that the outer surface of the inner jacket will grow a crystal layer, and the mother liquor will be discharged from the mother liquor outlet. The temperature of the jacket is raised to 35℃, the crystalli...

Embodiment 3

[0040] A method for separating milk fat based on melting layer crystallization technology, including the following steps:

[0041] (1) Prepare a crystallization device with a double jacket;

[0042] (2) Weigh 250g of anhydrous milk fat, raise the temperature to 63℃ under stirring, keep the temperature at constant temperature for 30 minutes, and put it into a crystallization tank with a double-jacketed crystallization device (the volume of the crystallization tank is 500ML), and control the outer layer The temperature of the circulating water in the jacket is 45°C, and the temperature of the inner jacket is reduced to 35°C within 60 minutes and maintained for 35 minutes;

[0043] (3) Decrease the temperature of the inner jacket to 27°C within 120 minutes, and maintain it at 27°C for 150 minutes, so that the outer surface of the inner jacket will grow a crystal layer, and the mother liquor will be discharged from the mother liquor outlet. The temperature of the jacket is increased to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com