Manufacturing method of SAPO-34 molecular sieve and application of SAPO-34 molecular sieve

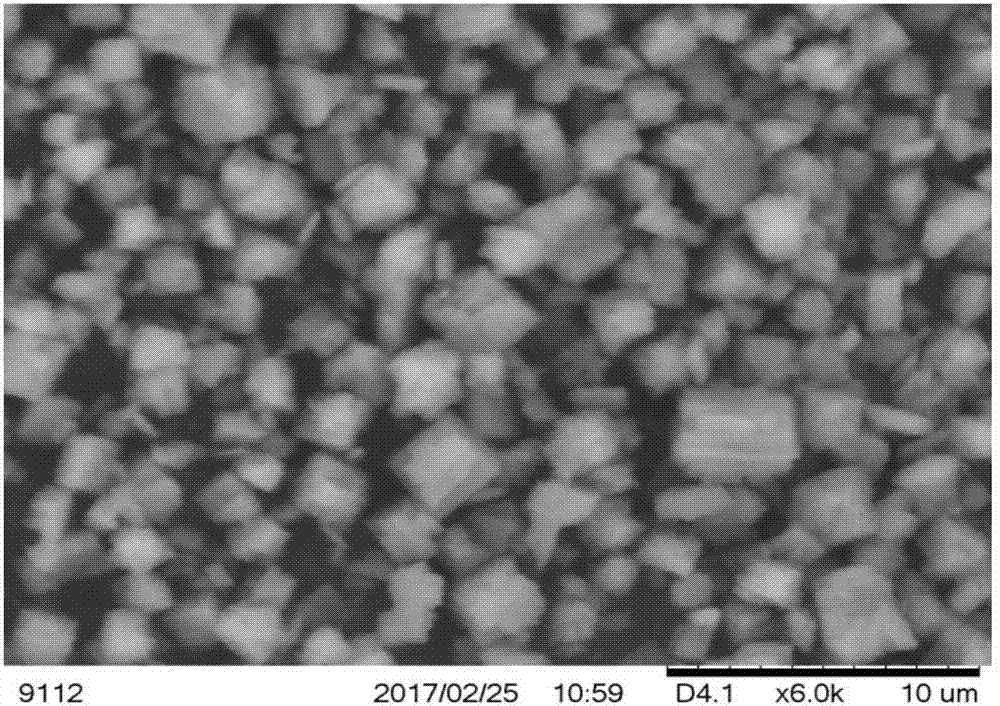

A technology of SAPO-34 and molecular sieve, which is applied in the direction of molecular sieve and alkali exchange phosphate, molecular sieve characteristic silicoaluminophosphate, and hydrocarbon production from oxygen-containing organic compounds, etc. It can solve the problems of increasing propane, accelerating catalyst deactivation, and unfavorable diene selection In order to achieve the effects of high selectivity, long catalyst life and small crystal grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

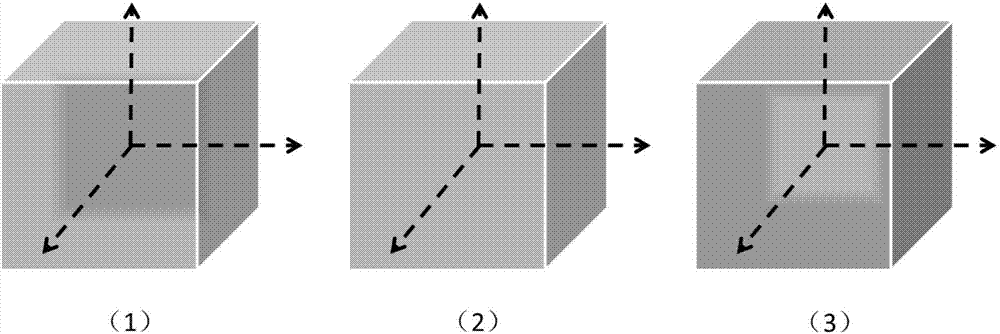

[0061] (1) Gel preparation: First, 209.52 kg of distilled water was added to a 1000L high-pressure reactor, the stirring speed was 100 rpm, and 101.25 kg of pseudo-boehmite with a solid content of 70wt.% was slowly added, and preheated at 40°C. Preheat the high-temperature oil and control the temperature, then slowly add 166.35 kg of phosphoric acid with a concentration of 85wt.%, stir evenly, then slowly add 10.52 kg of silica sol with a concentration of 40wt.%, stir evenly, and finally add 294.60 kg of phosphoric acid with a concentration of 25wt.%. Tetraethylammonium hydroxide aqueous solution, then add 21.3 kilograms of diethylamine templating agent, increase the stirring speed to 500 rev / min, stir for 18 hours, make the system become uniform gel; Cut at 5000 rpm for 40 minutes. Aging at room temperature (25°C) for 16 hours.

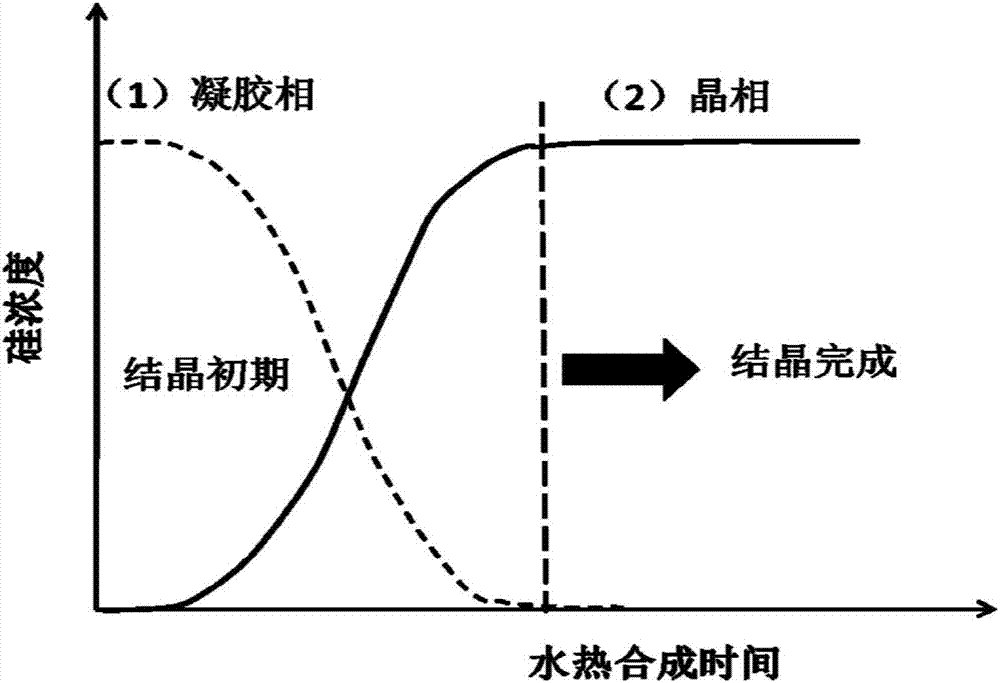

[0062] (2) Crystallization: the system was raised from room temperature to 170°C with a heating rate of 0.36°C / min. After stabilizing at 170°C for...

Embodiment 2

[0069] (1) Gel preparation: First, 254.42 kilograms of distilled water is added to a 1000L high-pressure reactor, the stirring speed is 100 rpm, and 122.94 kilograms of pseudo-boehmite with a solid content of 70wt.% is slowly added, and it is heat-resistant at 40 ° C. Oil is carried out preheating, temperature control, then slowly add 201.99 kilograms of concentration and be the phosphoric acid of 85wt.%, stir evenly, then slowly add 12.77 kilograms of concentration and be the silica sol (the neutral silica sol of Sigma Aldrich chemical company) of 40wt.% and stir Evenly, finally add 357.72 kilograms of tetraethylammonium hydroxide aqueous solution with a concentration of 25wt.%, then add 30.4 kilograms of triethylamine template agent and 21.3 kilograms of diethylamine template agent, increase the stirring speed to 500 rpm, stir for 18 hour, make the system a homogeneous gel; the homogeneous gel of the previous step was sheared for 60 minutes at 6000 rpm on a homogenizer. Aged...

Embodiment 3

[0077] (1) Gel preparation: First, 248.44 kg of distilled water is added to a 1000L high-pressure reactor, the stirring speed is 100 rpm, and 120.5 kg of pseudo-boehmite with a solid content of 70wt.% is slowly added, and it is heat-resistant at 40°C. The oil is preheated and temperature controlled, then slowly add 197.24 kg of phosphoric acid with a concentration of 85wt.%, stir evenly, then slowly add 12.47 kg of silica sol with a concentration of 40wt.%, stir evenly, and finally add 349.32 kg of phosphoric acid with a concentration of 25wt.%. Tetraethylammonium hydroxide aqueous solution, then add 30.4 kilograms of triethylamine templating agent, increase stirring speed to 320 rev / min, stir for 20 hours, make system become homogeneous gel; 5500 rpm shearing for 40 minutes. Aging at room temperature 40°C for 16 hours.

[0078] (2) Crystallization: The system was raised from room temperature to 160°C with a heating rate of 0.04°C / min. After stabilizing at 160°C for 2 hours,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com