Mineralized collagen material, preparation method and application

A collagen material and collagen technology, applied in medical science, prosthesis and other directions, can solve the problems of high industrialization cost, poor mineralization uniformity, complicated preparation steps, etc., and achieve the effect of excellent flexibility and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

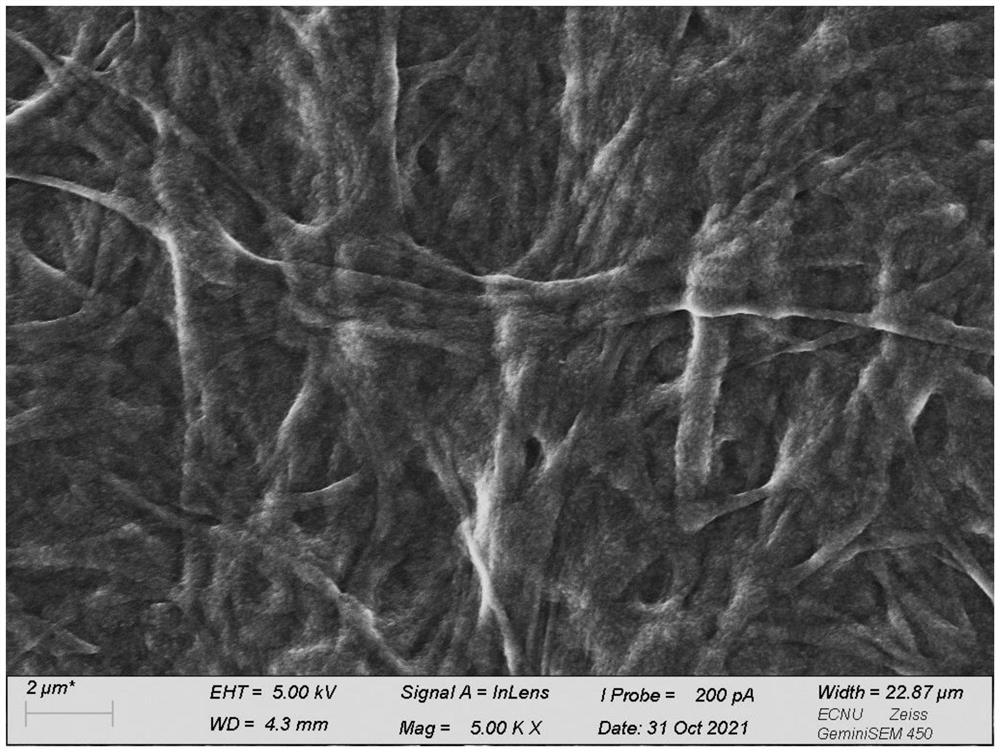

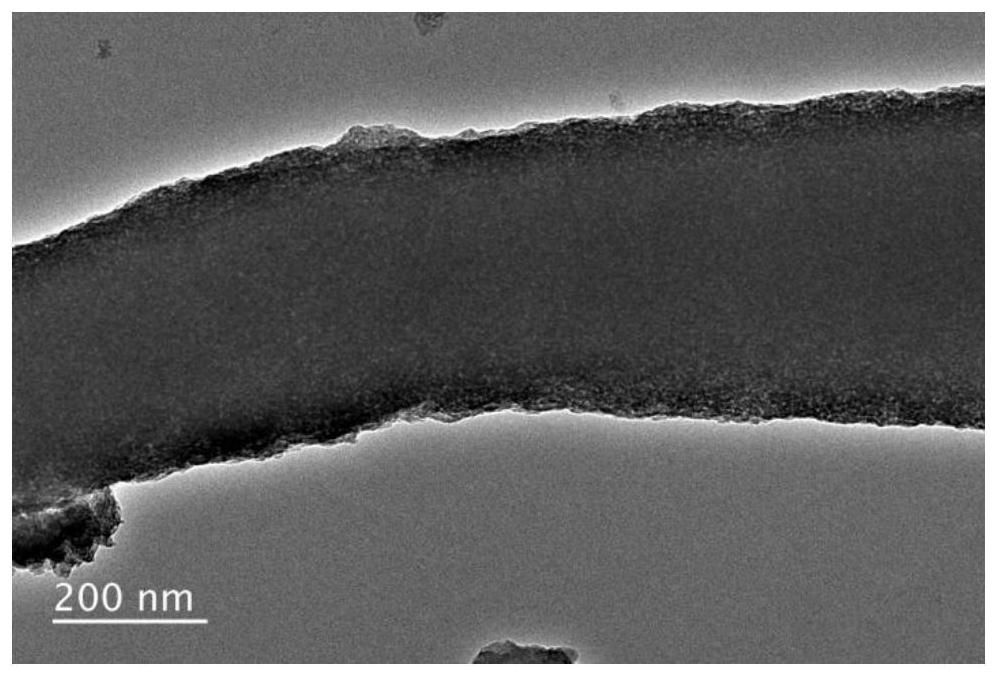

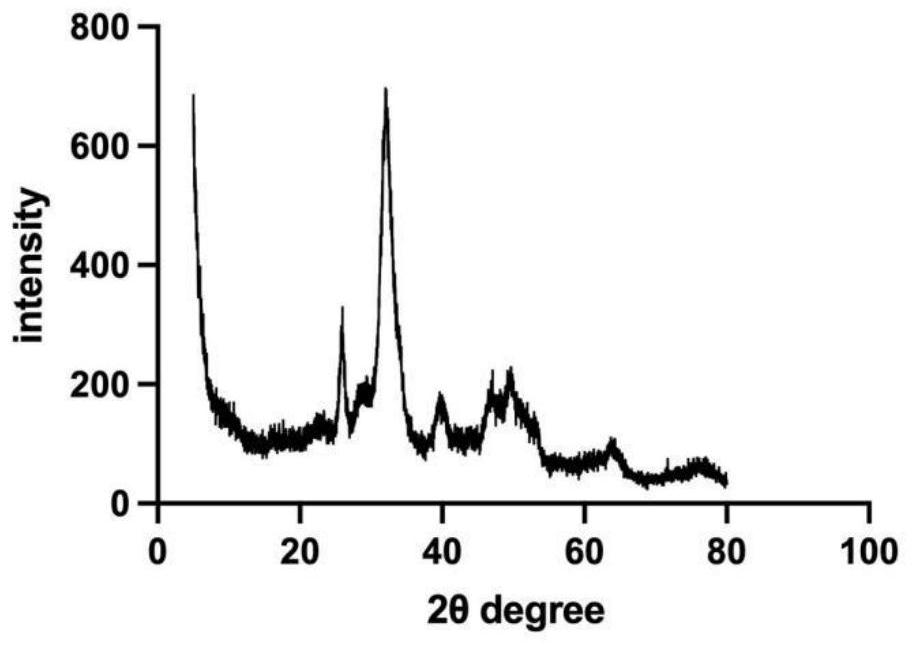

[0068] The present embodiment is an exemplary embodiment of the present invention, and relates to a mineralized collagen material, a preparation method and an application thereof.

[0069] A preparation method of a mineralized collagen material, comprising:

[0070] Step S102, dissolving type I collagen, calcium source and acid in a first solvent to obtain a first solution, wherein the first solvent is glycerol or a mixed solvent of glycerol and water;

[0071] Step S104, dissolving the alkali and the phosphorus source in a second solvent to obtain a second solution, wherein the second solvent is glycerol or water or a mixed solvent of glycerol and water;

[0072] Step S106, when the temperature is less than or equal to 45°C, adding the second solution to the first solution and mixing to obtain a third solution, wherein the pH of the third solution is greater than or equal to 7;

[0073] Step S108, soaking the third solution in a deionized water solvent or an ethanol solvent ...

Embodiment 2

[0131] This embodiment is a specific embodiment of the present invention.

[0132] Add calcium chloride, porcine-derived collagen and acetic acid to the glycerol / water mixture (the mass ratio of glycerol and water is 2:3) at room temperature under stirring with a magnetic stirring bar (rotation speed is 500-600 rpm / min) to prepare A first solution containing 0.06 M calcium chloride, 0.1 M acetic acid and 15 mg / mL collagen was prepared.

[0133] Trisodium phosphate and sodium hydroxide were dissolved in glycerol to prepare a second solution containing 0.05M trisodium phosphate and 0.5M sodium hydroxide.

[0134] 3.2 mL of the second solution was slowly dropped into 4.6 mL of the first solution at 10° C. under stirring with a magnetic stirring bar (800-1000 rpm), and mixed thoroughly to obtain the third solution.

[0135] The third solution was placed at room temperature, and the contents were taken out after 1 day, immersed in deionized water repeatedly, and freeze-dried to pr...

Embodiment 3

[0137] This embodiment is a specific embodiment of the present invention.

[0138] Add calcium chloride, mouse-derived collagen and acetic acid into deionized water at room temperature under stirring with a magnetic stirring bar (rotation speed 500-600 rpm) to prepare a mixture containing 0.1M calcium chloride, 0.1M acetic acid and 5mg / mL The first solution of collagen.

[0139] Trisodium phosphate and sodium hydroxide were dissolved in glycerol to prepare a second solution containing 0.05M trisodium phosphate and 0.5M sodium hydroxide.

[0140] 3.2 mL of the second solution was slowly dropped into 5.0 mL of the first solution at 10° C. under stirring with a magnetic stirring bar (800-1000 rpm), and mixed thoroughly to obtain the third solution.

[0141] The third solution was placed at room temperature, and the contents were taken out after 2 days, immersed in deionized water repeatedly, and freeze-dried to prepare a mineralized collagen scaffold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com