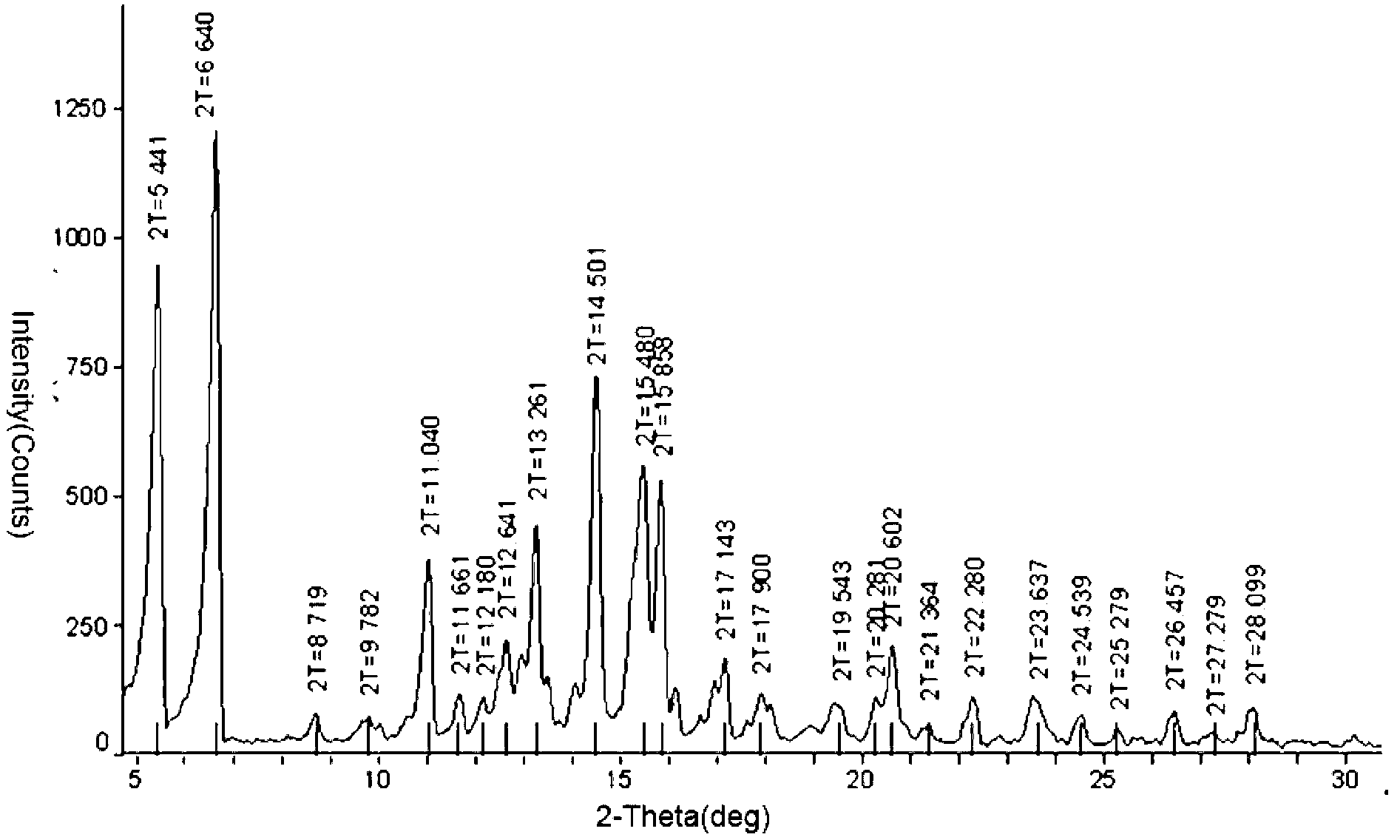

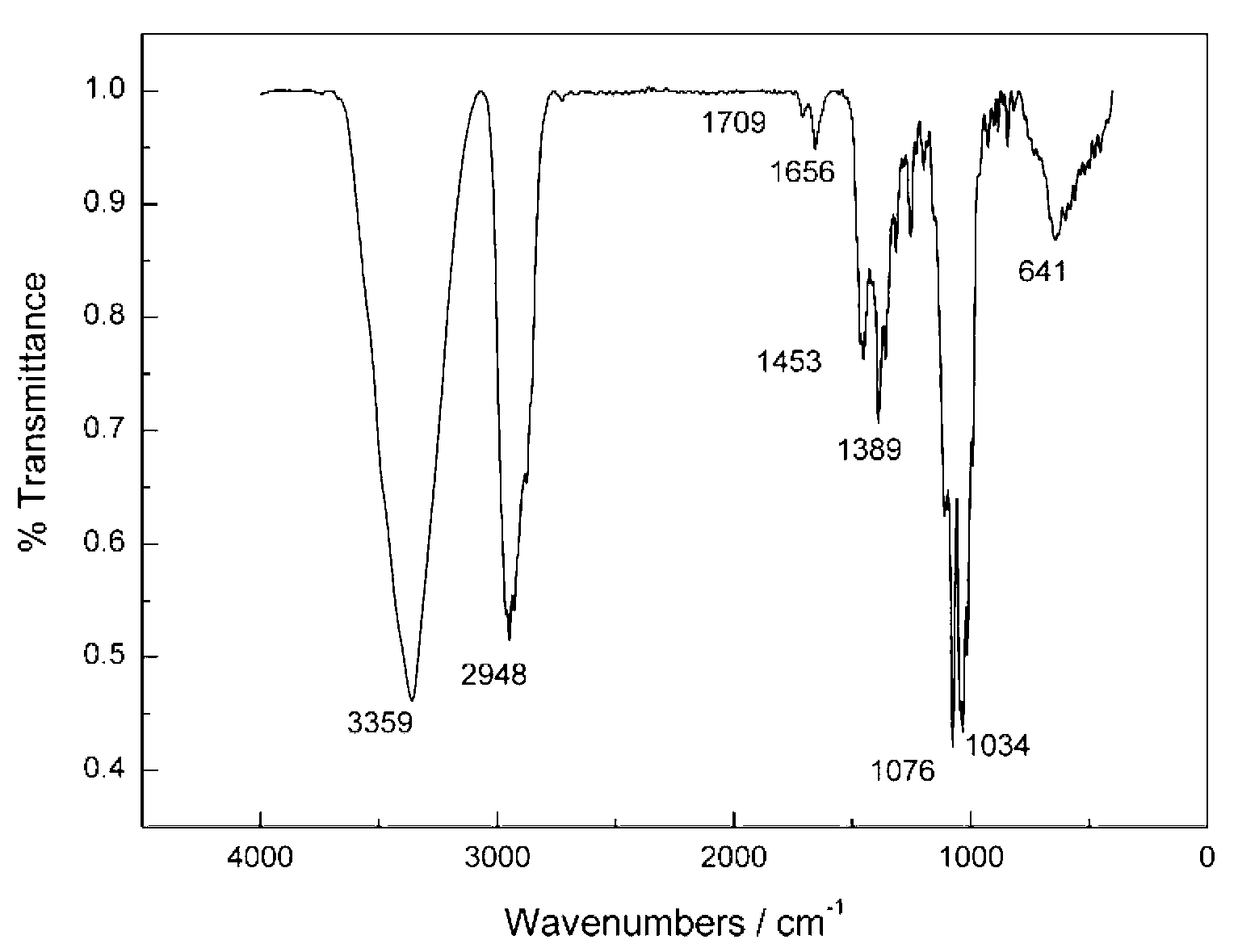

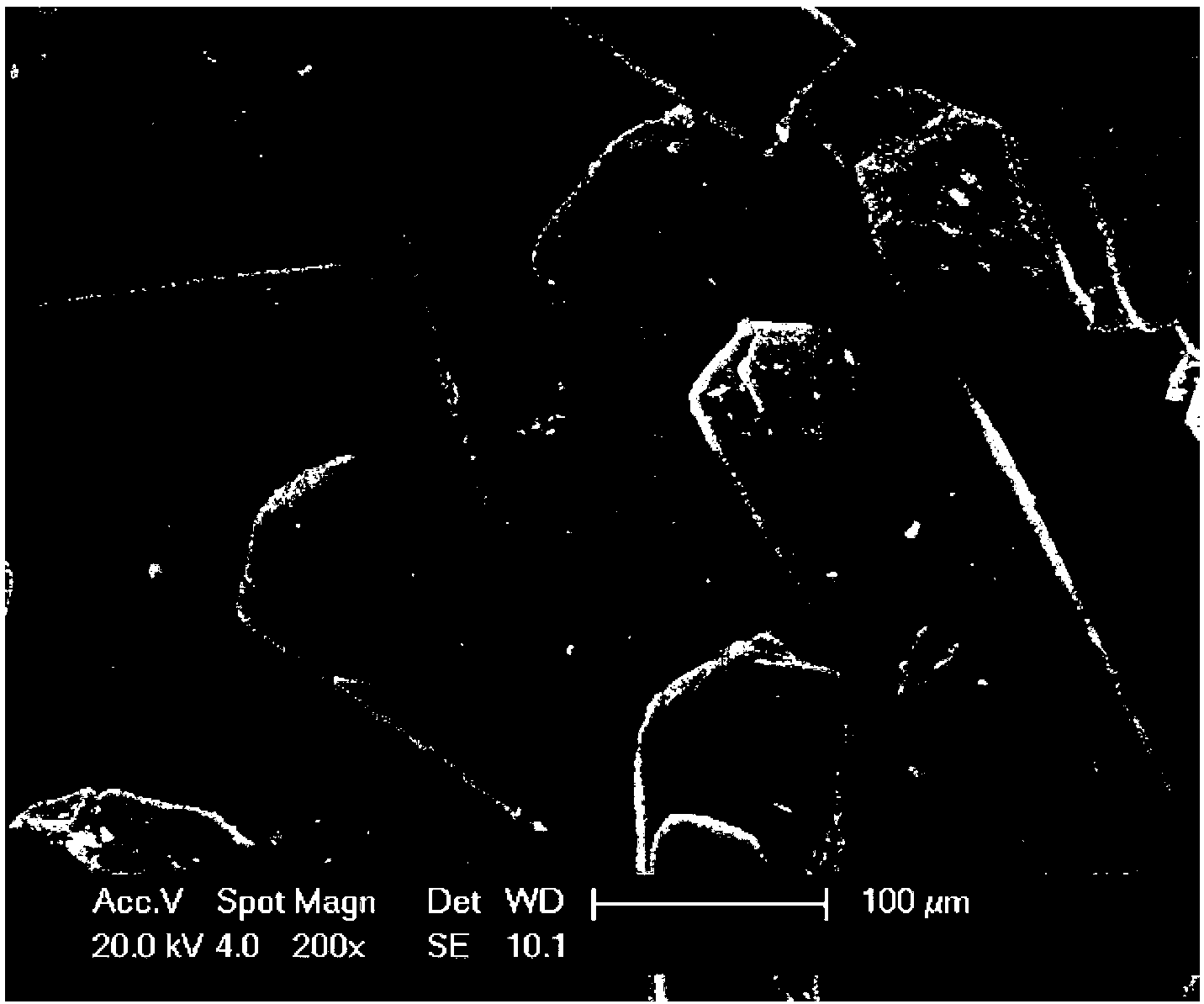

Ginsenoside C-K semihydrate crystal and preparation method thereof

A technology of ginsenoside and hemihydrate, applied in the direction of steroids, organic chemistry, etc., to achieve the effect of controlling crystal nucleation, uniform particle size distribution, and improving crystallization yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The method that this example produces ginsenoside C-K hemihydrate crystal specifically comprises the following steps:

[0030] 1) Add 22.3950g of crude ginsenoside C-K to 290ml of acetone and water mixed solvent with a mass ratio of 4:1, dissolve it completely at 50°C, then raise the temperature to 53°C to ensure that ginsenoside C-K is completely dissolved, and add Condensation reflux device to avoid solvent volatilization;

[0031] 2) Cool down the saturated solution obtained above at a rate of 0.1°C / min, add 1% seed crystals when the temperature drops to 40°C, and maintain the seeding temperature for 60 minutes to consume the supersaturation in the solution;

[0032] 3) After constant temperature stirring, continue to drop the temperature to 4°C at a cooling rate of 0.2°C / min, grow crystals at 4°C for 1 hour, filter and wash, and dry at 50°C for 1 hour under a vacuum of 0.08Mp-0.1Mp to obtain the product Ginsenoside C-K hemihydrate, the yield is more than 92%.

[0...

Embodiment 2

[0037] The method that this example produces ginsenoside C-K hemihydrate crystal specifically comprises the following steps:

[0038] 1) Add 15.0205g of crude ginsenoside C-K to 320ml of acetone and water mixed solvent with a mass ratio of 10:1, dissolve it completely at 50°C, then raise the temperature to 53°C to ensure that ginsenoside C-K is completely dissolved, and add Condensation reflux device to avoid solvent volatilization;

[0039] 2) Cool down the saturated solution obtained above at a rate of 0.05°C / min, add 0.5% seed crystals when the temperature drops to 42°C, and maintain the seeding temperature for 60 minutes to consume the supersaturation in the solution;

[0040] 3) After constant temperature stirring, continue to drop the temperature to 4°C at a cooling rate of 0.1°C / min, grow crystals at 4°C for 1 hour, filter and wash, and dry at 45°C for 1 hour under a vacuum of 0.08Mp-0.1Mp to obtain the product Ginsenoside C-K hemihydrate, the yield is greater than 91%...

Embodiment 3

[0045] The method that this example produces ginsenoside C-K hemihydrate crystal specifically comprises the following steps:

[0046] 1) Add 18.1238g of crude ginsenoside C-K to 300ml of acetone and water mixed solvent with a mass ratio of 8:1, dissolve it completely at 50°C, then raise the temperature to 53°C to ensure that ginsenoside C-K is completely dissolved, and add Condensation reflux device to avoid solvent volatilization;

[0047] 2) Cool down the saturated solution obtained above at a rate of 0.2°C / min, add 3% seed crystals when the temperature drops to 38°C, and maintain the seeding temperature for 60 minutes to consume the supersaturation in the solution;

[0048] 3) After constant temperature stirring, continue to drop the temperature to 4°C at a cooling rate of 0.3°C / min, grow crystals at 4°C for 1 hour, filter and wash, and dry at 60°C for 1 hour under a vacuum of 0.08Mp-0.1Mp to obtain the product Ginsenoside C-K hemihydrate, the yield is more than 90%.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com