Preparation method of silicon oxide nanoparticles with uniform particle sizes

A nano-silica, silicon dioxide technology, applied in the direction of silicon oxide, silicon dioxide, nanotechnology, etc., can solve the problem of poor batch repeatability, huge influence of particle size, difficulty in controlling the uniformity and shape of nanoparticles, etc. problems, to achieve the effect of achieving scale and uniformity, reducing the concentration of metal impurities, and achieving batch stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

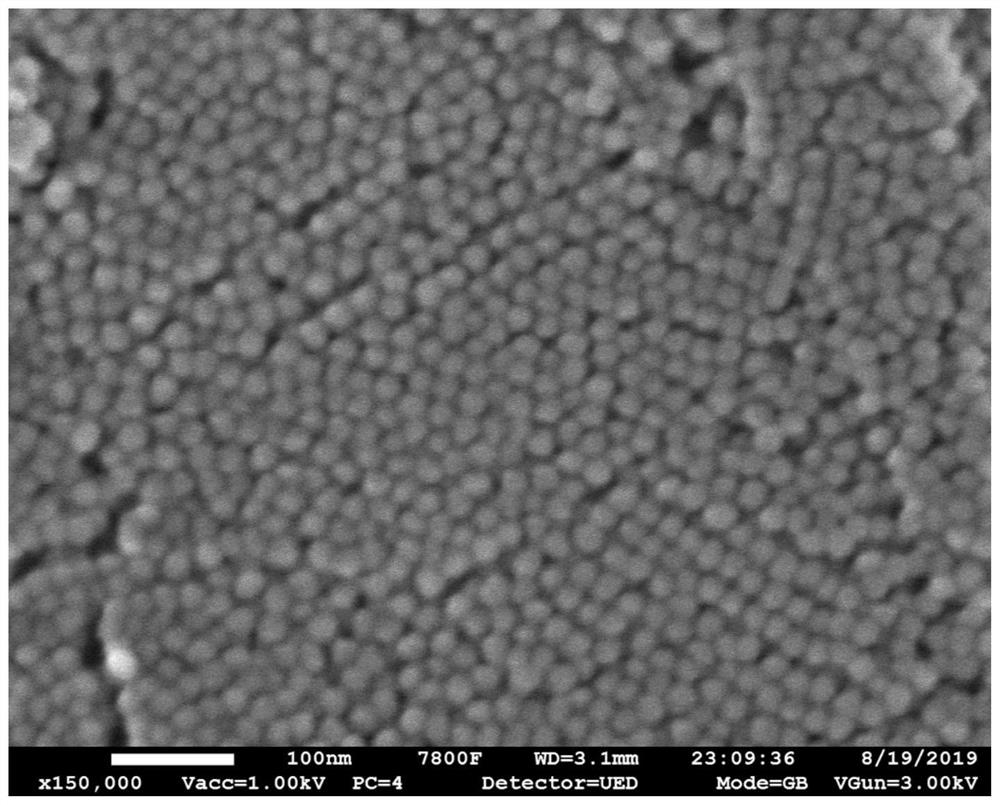

Embodiment 1

[0080] Step 1, weigh the water glass sodium silicate raw material of 50g, wherein the silicon dioxide concentration of sodium silicate is 21wt%, the modulus SiO of sodium silicate 2 :Na 2 O=3.3:1; 160g of deionized water was added to the above sodium silicate solution, and stirred evenly to obtain a diluted inorganic sodium silicate solution.

[0081] The obtained cation exchange resin, model 731, will be purchased. Put the cation exchange resin into water and wash it until the solution does not contain impurities. Then use 4wt% hydrochloric acid to wash, and then use deionized water to wash until the washing water is neutral. Then the above diluted inorganic sodium silicate solution was added to obtain the required 5 wt.% concentration of orthosilicic acid solution.

[0082] Step 2. Mix 27 g of tetramethoxysilane and 5.6 g of methanol, then add to the orthosilicic acid solution obtained in step 1 and mix and stir to obtain an organic-inorganic hybrid solution of silicon so...

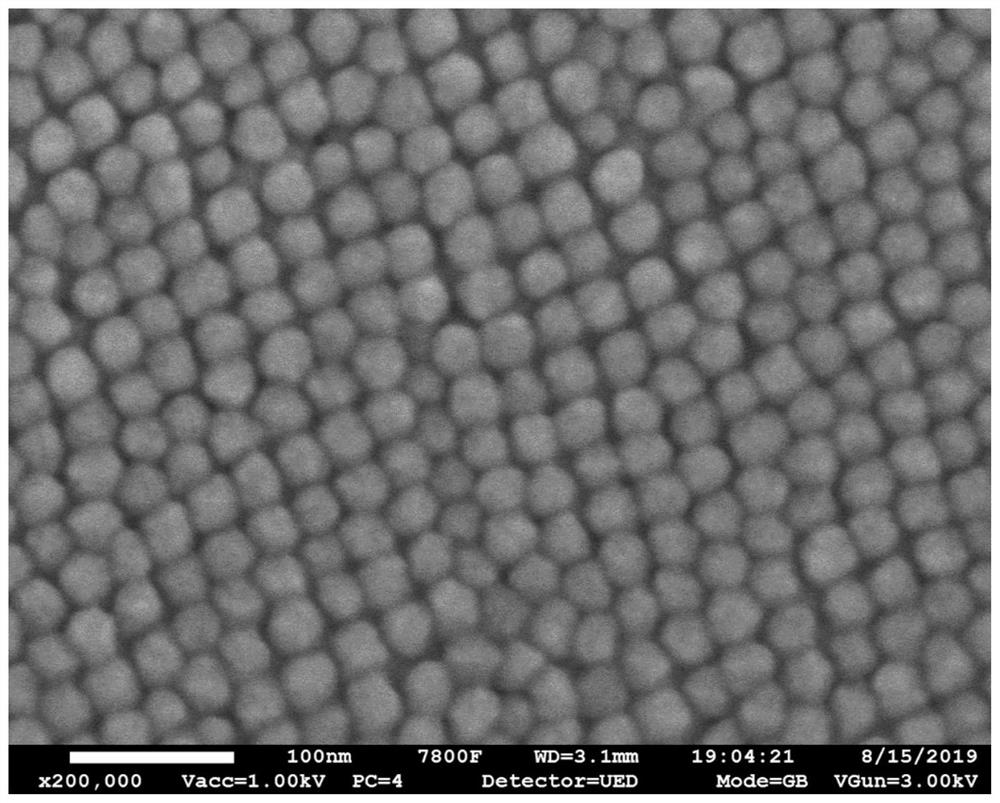

Embodiment 2

[0085] Step 1, weigh the water glass sodium silicate raw material of 50g, wherein the silicon dioxide concentration of sodium silicate is 21%, the modulus SiO of sodium silicate 2 :Na 2 O=3.3:1; 160g of deionized water was added to the above sodium silicate solution, and stirred evenly to obtain a diluted inorganic sodium silicate solution.

[0086] The obtained cation exchange resin, model 731, will be purchased. Put the cation exchange resin into water and wash it until the solution does not contain impurities. Then use 4wt% hydrochloric acid to wash, and then use deionized water to wash until the washing water is neutral. The above-mentioned inorganic sodium silicate solution was added to obtain a 5 wt.% concentration of orthosilicic acid solution.

[0087] Step 2. Mix 27 g of tetramethoxysilane and 5.6 g of methanol, then add to the orthosilicic acid solution obtained in step 1 and mix and stir to obtain an organic-inorganic hybrid solution of silicon source;

[0088] ...

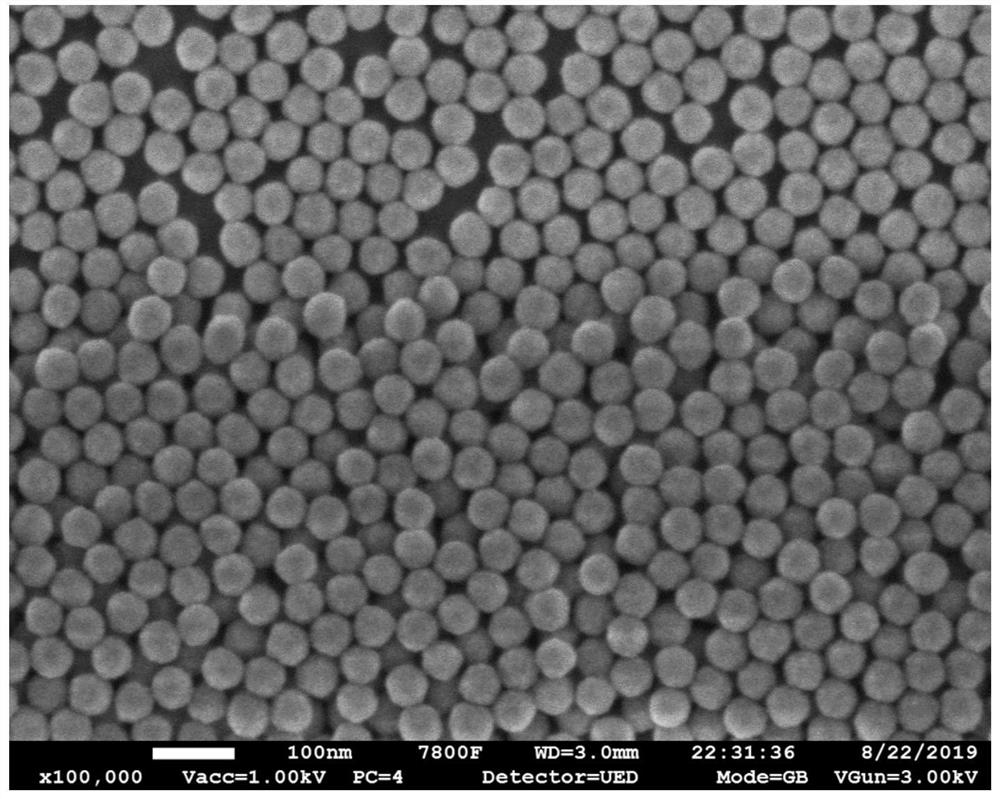

Embodiment 3

[0090] The difference between sample 3# and sample 2# is: the primer crystal seed in the step 3 in the embodiment 2 is changed into sample 2#, and others are all identical operating steps, and the nano silicon dioxide mark that obtains is sample 3#.

[0091] The difference between sample 4# and sample 2# is: the base material seed crystal in step 3 in the embodiment 2 is changed into sample 3#, and others are all the same operation steps, and the nano silicon dioxide mark that obtains is sample 4#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com