Hydraulic bulging machine

A hydraulic bulging and hydraulic transmission technology, which is applied in the field of hydraulic bulging machines, can solve the problems of high processing cost, difficult forming, and long processing cycle, and achieve the effects of low maintenance and energy consumption costs, easy implementation, and simple and compact design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

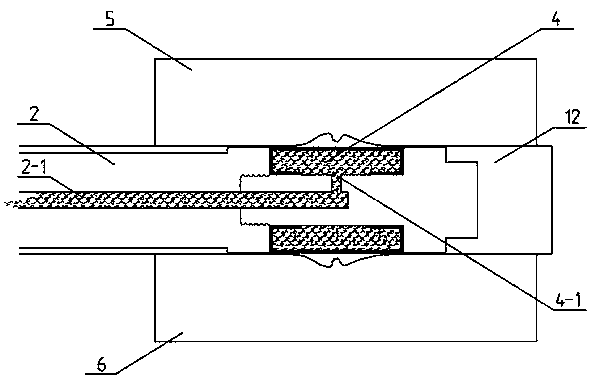

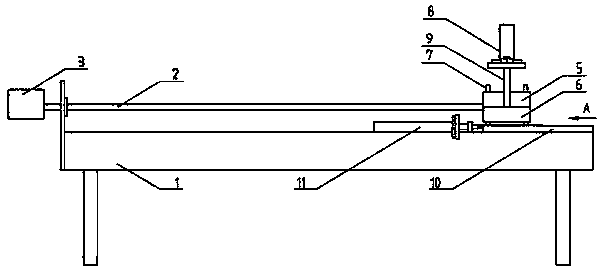

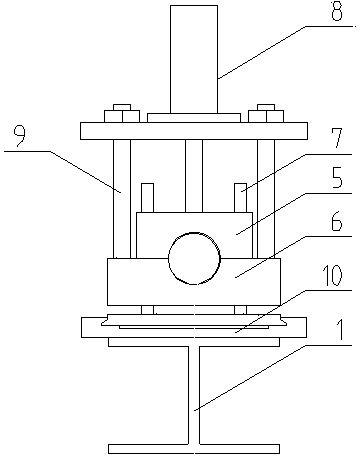

[0015] refer to Figure 2~3 , the composition of the embodiment includes a frame 1, a high-pressure pipe 2, a liquid channel 2-1, an ultra-high pressure pump 3, a rubber bag 4, a liquid filling port 4-1, an upper mold 5, a lower mold 6, a guide post 7, a mold opening Combine oil cylinder 8, oil cylinder support bar 9, track 10 and travel oil cylinder 11. Among them, the high-pressure pipe 2, the ultra-high-pressure pump 3 and the rubber bag 4 constitute a hydraulic transmission mechanism, which is used to transmit the pressure to the processing part of the metal imitation bamboo pipe; the upper mold 5, the lower mold 6, the guide post 7, and the mold opening and closing cylinder 8, oil cylinder support bar 9, track 10, walking oil cylinder 11 and slide block constitute forming mechanism, are used for processing the processing position of metal imitation bamboo pipe into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com