Integrated treatment device and method for livestock slaughtering and domestic sewage and cooked food processing wastewater

A technology for domestic sewage and treatment devices, which is applied in the fields of food industry wastewater treatment, animal processing wastewater treatment, water/sewage multi-stage treatment, etc. The effect of high oil and protein content and large water quality fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

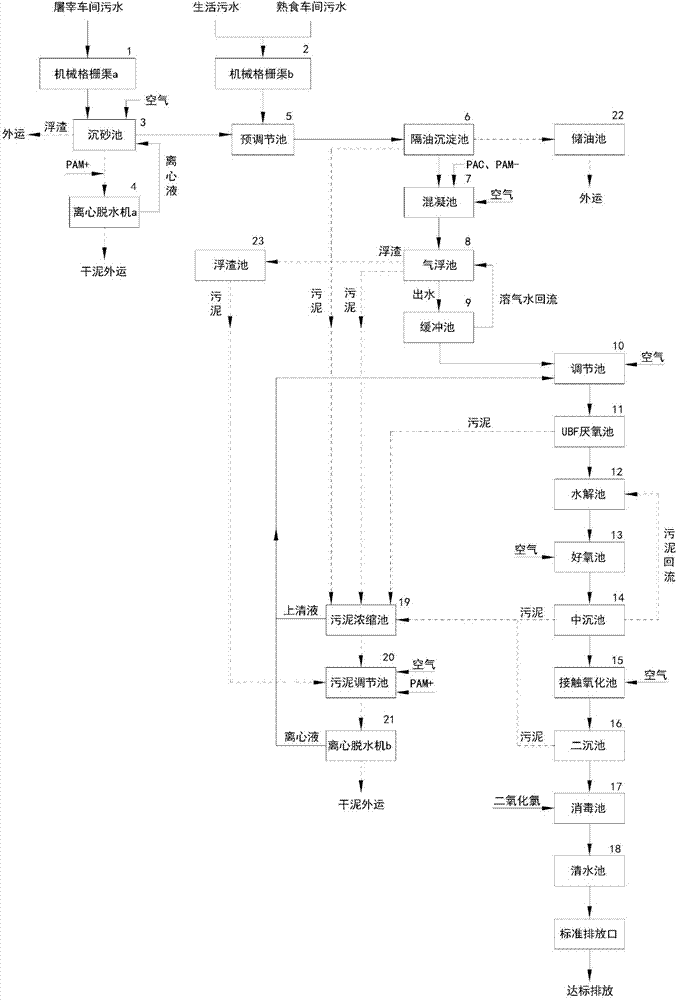

[0015] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0016] refer to figure 1 , a treatment device for livestock and poultry slaughtering, domestic sewage and cooked food processing wastewater. The sewage treated by the device comes from three parts, namely slaughter workshop sewage, domestic sewage, and cooked food workshop sewage. The treatment process of slaughter workshop sewage includes mechanical grilles connected in sequence Canal (a) 1, grit chamber 3, preconditioning pond 5, oil separation sedimentation pond 6, coagulation pond 7, air flotation pond 8, buffer pond 9, regulating pond 10, UBF anaerobic pond 11, hydrolysis pond 12, well Oxygen tank 13, medium sedimentation tank 14, contact oxidation tank 15, secondary sedimentation tank 16, disinfection tank 17, clear water tank 18. The domestic sewage and the cooked food workshop sewage are collected together and then pass through the mechanical gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com