Integrated treating and reusing device for heavy metal chemical leaching liquid waste and method for treating and reusing leaching liquid

A chemical leaching and waste liquid treatment technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as poor acid and alkali tolerance, easy pollution, complex components, etc. problems, to achieve the effect of small footprint, convenient and flexible transportation, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

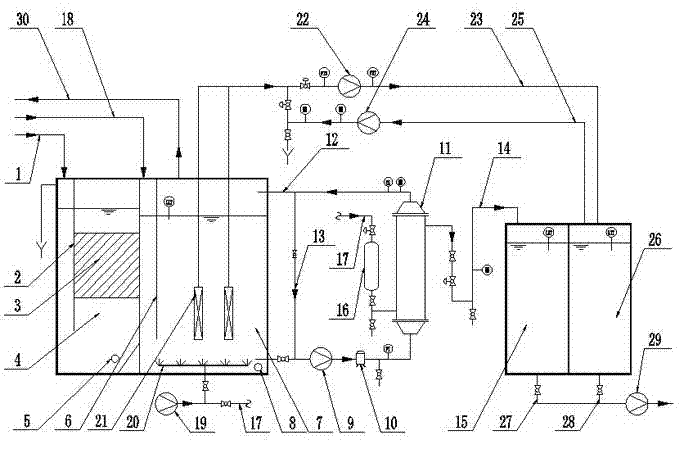

[0043] An integrated device for the treatment and reuse of heavy metal chemical leaching waste liquid, such as figure 1 As shown, it mainly includes the following parts: 1) inclined tube sedimentation tank 4; 2) rinsing waste liquid reaction tank 7; 3) inorganic ceramic membrane filter 11; 4) recovery liquid collection tank 15,26.

[0044] A deflector is set at the front end of the inclined tube sedimentation tank, and the chemical leaching waste liquid first enters the bottom of the inclined tube sedimentation tank from the diversion area, rises from the bottom and passes through the inclined tube packing, and under the action of the inclined tube packing, the waste liquid in the leaching The large particles of impurities and particles settle to the bottom of the tank, and the clear liquid rises and flows into the leaching waste liquid reaction tank; there are sludge discharge holes at the bottom of the inclined tube sedimentation tank, and the sludge at the bottom is regularl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com