Process for purifying nosiheptide by passing through column

A Nosiheptide and column-passing technology, which is applied in the fields of peptide, organic chemistry, and peptide preparation methods, can solve problems such as difficult to achieve content, difficult to remove Nosiheptide impurities, and Nosiheptide decomposition, so as to achieve less decomposition and avoid Long purification time and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

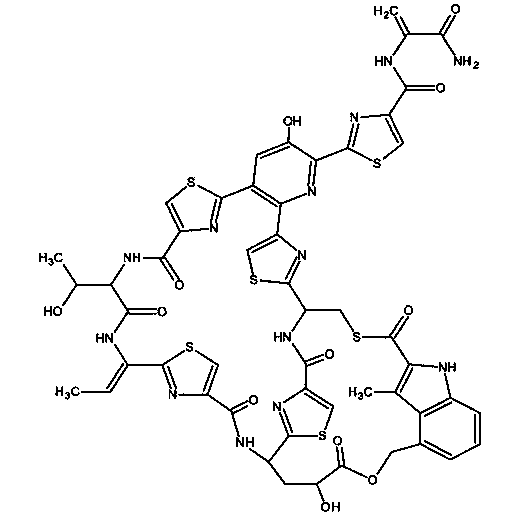

Image

Examples

Embodiment 1

[0025] The process of column purification of nosiheptide, its concrete steps are as follows:

[0026] (1) Add 2 g of nosiheptide crude product (content 70%) into 30 ml of mixed solvent (acetone:methanol 80% volume ratio 1:1), add acid to adjust the pH value to completely dissolve nosiheptide;

[0027] (2) After the macroporous adsorption resins HPD-100 and HPD-500 were pretreated with acetone and methanol in sequence, they were mixed according to the ratio of 1:2 and then wet-loaded into a chromatography column with a column diameter ratio of 15:1;

[0028] (3) Pass the previously configured nosiheptide solution through the mixed resin column, control the flow rate to 5ml / min, and collect the column liquid;

[0029] (4) Neutralize to neutral with alkali, concentrate under reduced pressure to one-tenth of the original volume, a large amount of solids precipitate out, filter, wash the filter cake with water, and dry under reduced pressure to obtain 1.11g of purified Nosiheptide ...

Embodiment 2

[0031] The process of column purification of nosiheptide, its concrete steps are as follows:

[0032] (1) Add 2 g of nosiheptide crude product (content 70%) into 40 ml of mixed solvent (acetone:methanol 80% volume ratio 1:1), add acid to adjust the pH value to completely dissolve nosiheptide;

[0033] (2) After the macroporous adsorption resins HPD-100 and HPD-500 were pretreated with acetone and methanol respectively, they were mixed according to the ratio of 3:5 and then wet-loaded into a chromatography column with a column diameter ratio of 15:1;

[0034] (3) Pass the previously configured nosiheptide solution through the mixed resin column, control the flow rate to 4ml / min, and collect the column liquid;

[0035] (4) Neutralize to neutral with alkali, concentrate under reduced pressure to one-tenth of the original volume, a large amount of solids precipitate out, filter, wash the filter cake with water, and dry under reduced pressure to obtain 1.14g of purified Nosiheptide...

Embodiment 3

[0037] (1) Add 2 g of nosiheptide crude product (content 70%) into 40 ml of mixed solvent (acetone:methanol 80% volume ratio 1:2), add acid to adjust the pH value to completely dissolve nosiheptide;

[0038] (2) After the macroporous adsorption resins HPD-100 and HPD-500 were pretreated with acetone and methanol in sequence, they were mixed according to the ratio of 3:4 and then wet-loaded into a chromatography column with a column diameter ratio of 15:1;

[0039] (2) Pass the previously configured nosiheptide solution through the mixed resin column, control the flow rate to 2ml / min, and collect the column liquid;

[0040] (3) Neutralize to neutral with alkali, concentrate under reduced pressure to one-tenth of the original volume, a large amount of solids precipitate out, filter, wash the filter cake with water, dry under reduced pressure to obtain 1.15g of purified nosiheptide, content 95.1% , The total recovery rate was 78.11%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com