A kind of thermoplastic polyurethane elastomer for keyboard film and preparation method thereof

A technology of thermoplastic polyurethane and polyurethane elastomer, which is applied in the field of polyurethane elastomer and its preparation, can solve the problems of rare polyurethane elastomer and achieve excellent yellowing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

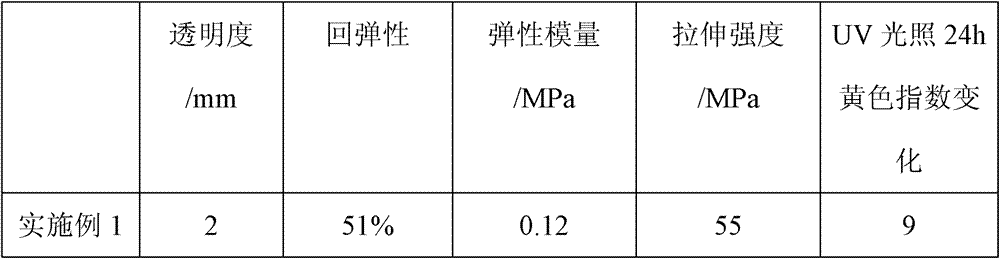

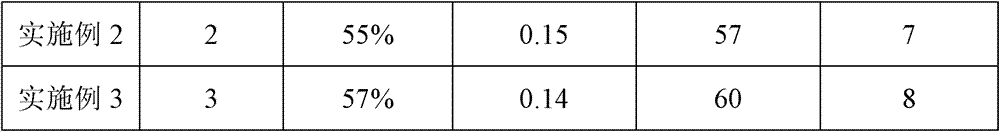

Examples

Embodiment 1

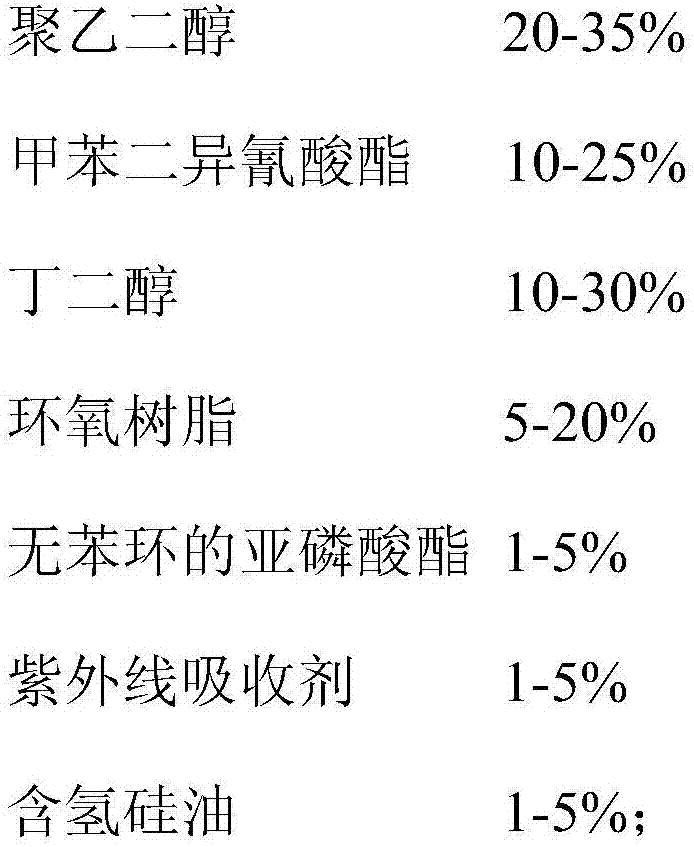

[0052] A thermoplastic polyurethane elastomer used for keyboard membranes, containing the following components by mass percentage:

[0053] Polyethylene Glycol 35%

[0054] Toluene diisocyanate 19%

[0055] Butanediol 30%

[0056] Epoxy 5%

[0057] Phosphite without benzene ring 1%

[0058] UV absorber 5%

[0059] Hydrogen silicone oil 5%; prepared as follows:

[0060] (1) Add phenolic resin to polyethylene glycol, vacuumize and dehydrate under 0.5kPa vacuum at 70°C;

[0061] (2) Dehydrate butanediol at 95°C under 0.2kPa vacuum; melt toluene diisocyanate at 68°C;

[0062] (3) Mix the mixture obtained in step (1) with the dehydrated butanediol in step (2) and heat at 90°C for 0.5h;

[0063] (4) Mix the toluene diisocyanate melted in step (2) with the mixture obtained in step (3) and other components, stir at 150°C for 3h, and then mature at 90°C for 12h;

[0064] (5) Granulating and injection molding the product obtained in step (4) to obtain the polyurethane elastomer. ...

Embodiment 2

[0066] A thermoplastic polyurethane elastomer used for keyboard membranes, containing the following components by mass percentage:

[0067] Polyethylene glycol 24%

[0068] Toluene diisocyanate 25%

[0069] Butanediol 20%

[0070] Epoxy 20%

[0071] Phosphite without benzene ring 5%

[0072] UV absorber 3%

[0073] Hydrogen silicone oil 3%; prepared as follows:

[0074] (1) Add phenolic resin to polyethylene glycol, vacuumize and dehydrate at 80°C under 0.2kPa vacuum;

[0075] (2) Dehydrate butanediol at 85°C under 0.5kPa vacuum; melt toluene diisocyanate at 57°C;

[0076] (3) Mix the mixture obtained in step (1) with the dehydrated butanediol in step (2) and heat at 80° C. for 1 hour;

[0077] (4) Mix the toluene diisocyanate melted in step (2) with the mixture obtained in step (3) and other components, stir at 155°C for 0.5h, and then mature at 85°C for 20h;

[0078] (5) Granulating and injection molding the product obtained in step (4) to obtain the polyurethane ela...

Embodiment 3

[0080] A thermoplastic polyurethane elastomer used for keyboard membranes, containing the following components by mass percentage:

[0081] Polyethylene Glycol 35%

[0082] Toluene diisocyanate 20%

[0083] Butanediol 10%

[0084] Epoxy 15%

[0085] Phosphite without benzene ring 3%

[0086] UV absorber 1%

[0087] Hydrogen silicone oil 2% and talc filler 14%; prepared by the following method:

[0088] (1) Add phenolic resin to polyethylene glycol, vacuumize and dehydrate at 75°C under 0.4kPa vacuum;

[0089] (2) dehydrating butanediol at 90°C under 0.3kPa vacuum; melting toluene diisocyanate at 60°C;

[0090] (3) Mix the mixture obtained in step (1) with the dehydrated butanediol in step (2) and heat at 85° C. for 2 hours;

[0091] (4) Mix the toluene diisocyanate melted in step (2) with the mixture obtained in step (3) and other components, stir at 145°C for 3h, and then mature at 95°C for 30h;

[0092] (5) Granulating and injection molding the product obtained in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com