Adhesive tape

A tape and adhesive layer technology, applied in the direction of adhesives, non-polymer adhesive additives, film/sheet adhesives, etc. problems, to achieve the effect of improving shear strength, simple manufacturing steps, and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

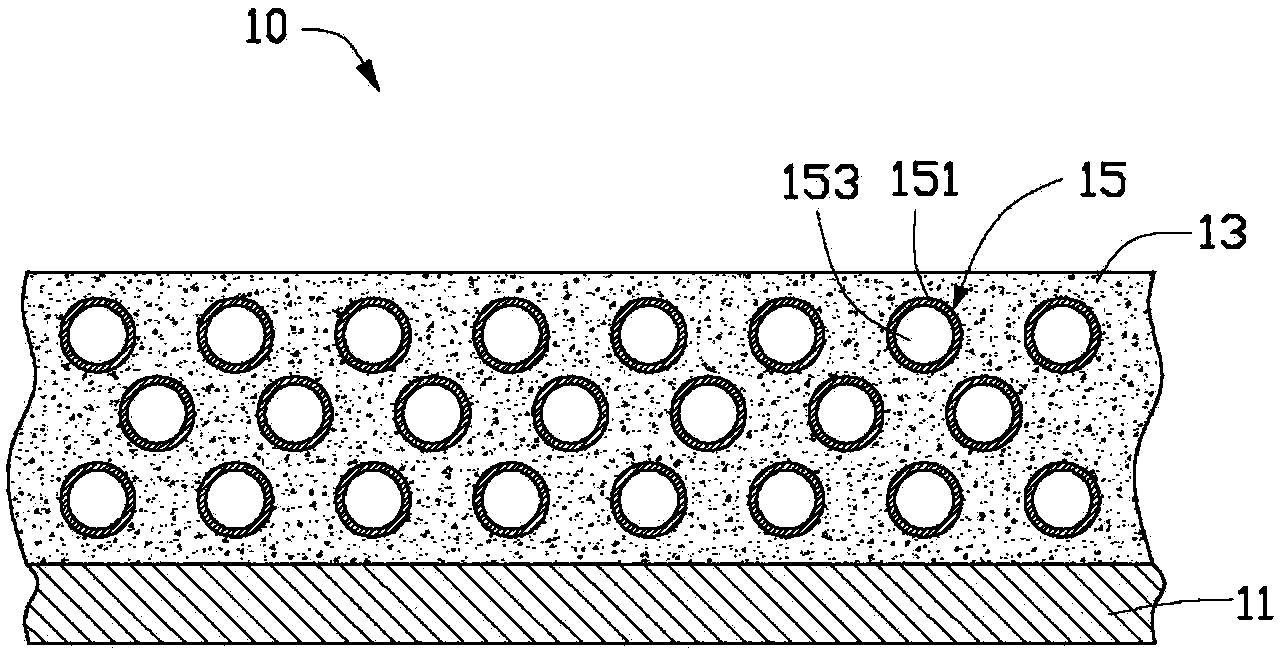

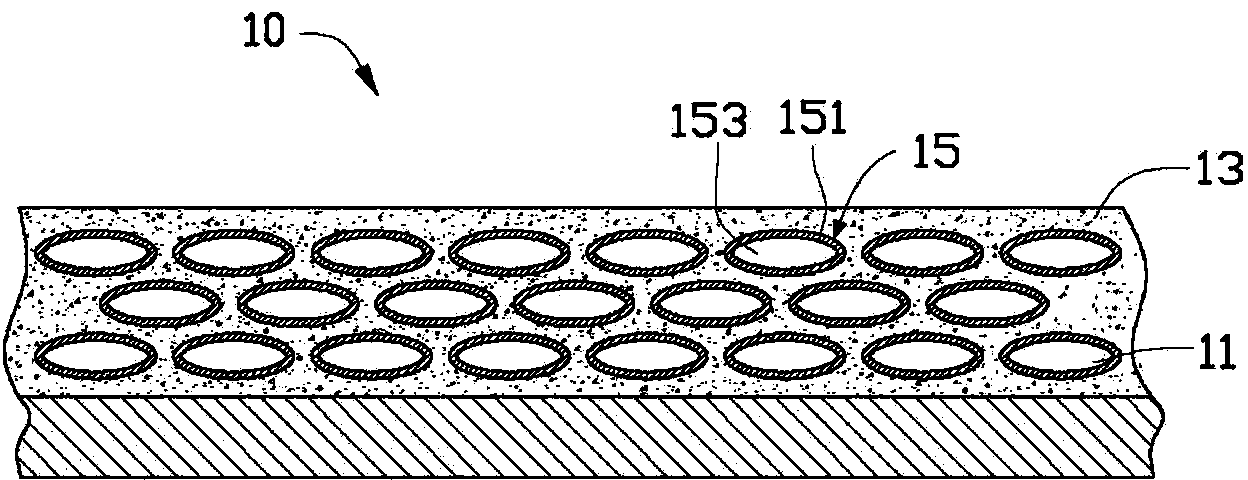

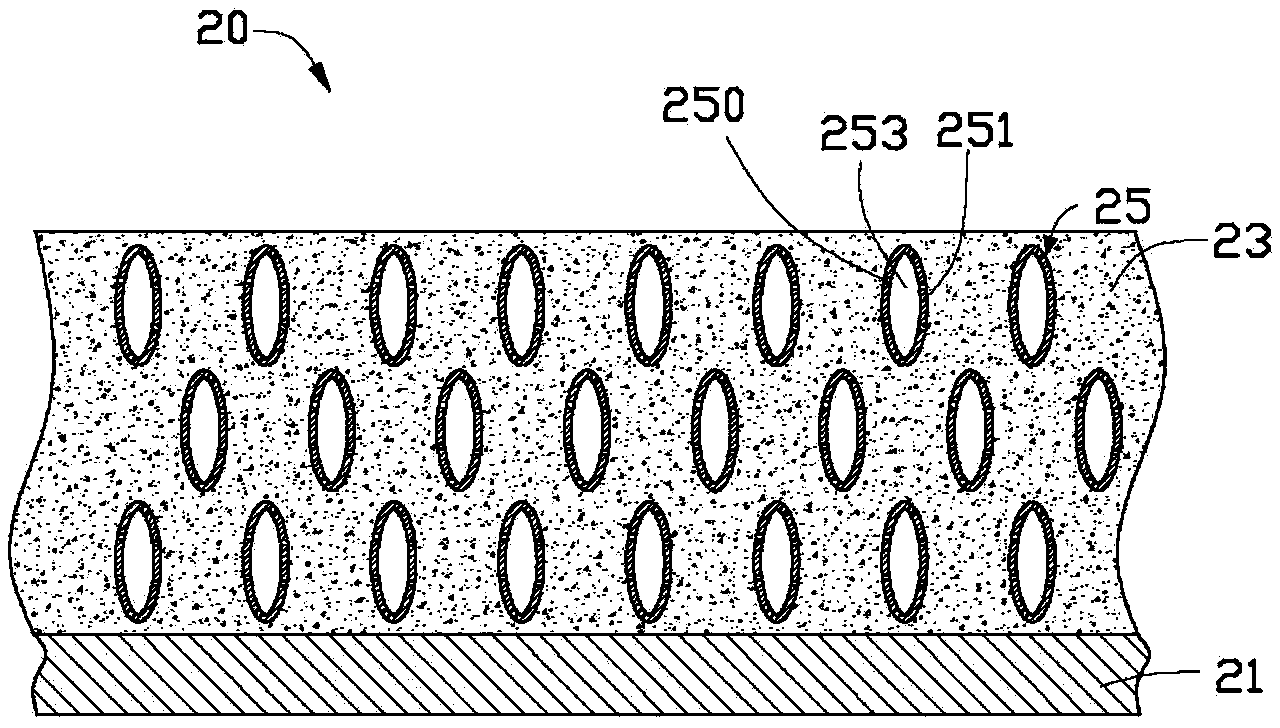

[0013] see figure 1 and figure 2 , The adhesive tape 10 according to the first embodiment of the present invention includes a release protection layer 11 , an adhesive layer 13 provided on the release protection layer 11 , and a plurality of carrier particles 15 dispersed in the adhesive layer 13 . The peeling protective layer 11 is a release paper. The adhesive layer 13 is made of adhesive and is used for bonding objects (not shown). The carrying particle 15 is a hollow sphere, which includes an elastic closed shell 151 , and the shell 151 forms a buffer space 153 . The material of the shell 151 includes at least one of organic polymer materials, metals and ceramic materials, wherein, when organic polymer materials are used, the carrier particles 15 can be prepared from at least one of the following materials: vinylidene chloride-acrylonitrile Copolymer, polyvinyl alcohol, polyvinyl butyral, polymethyl methacrylate, polyacrylonitrile copolymer, polyvinylidene chloride and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com