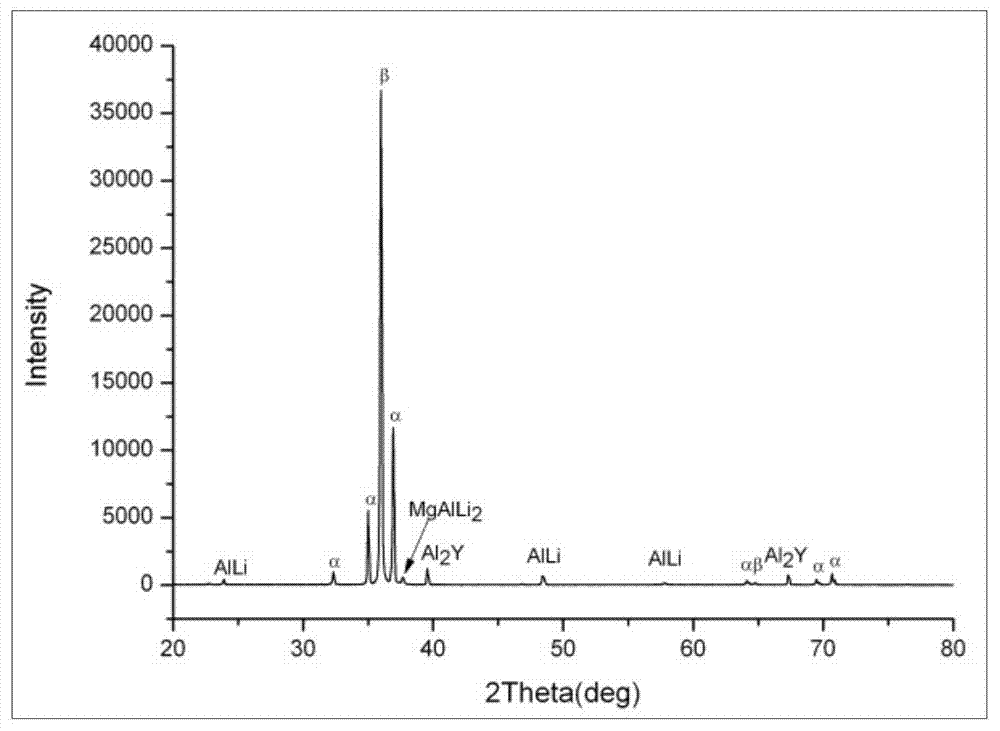

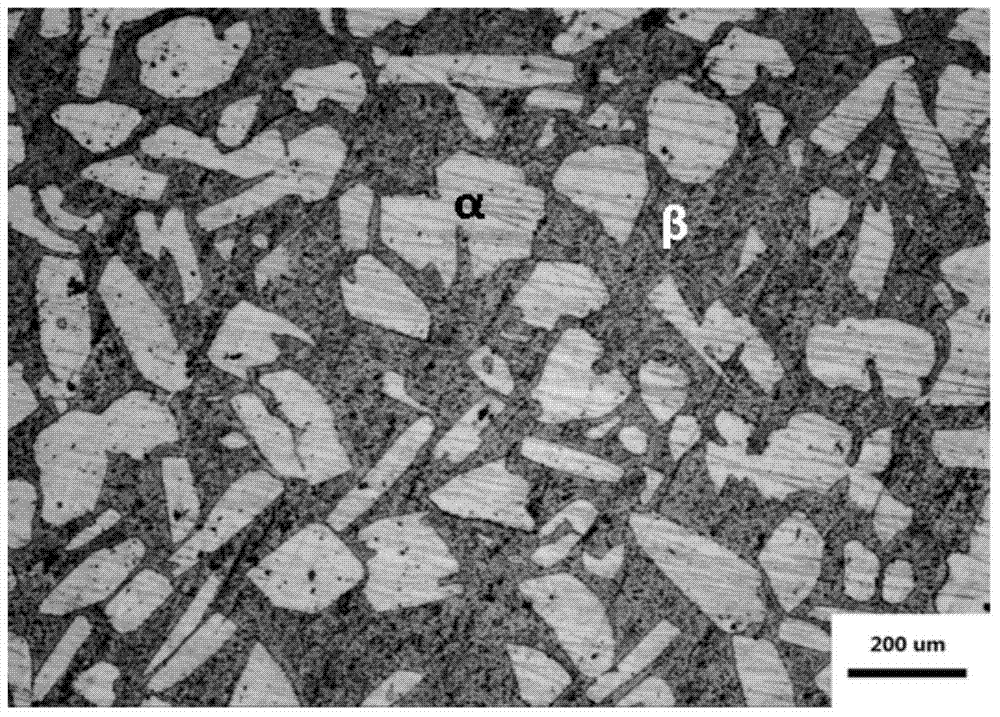

High-strength two-phase ultralight magnesium lithium alloy and preparation method thereof

A magnesium-lithium alloy, high-strength technology, applied in the field of light metal material preparation, can solve the problems of poor alloy structure and performance stability, low industrialization promotion value, increase alloy density, etc., to improve mechanical properties, facilitate commercial application, Strength-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The alloy consists of the following components by mass percentage:

[0058] Li: 7.91%

[0059] Al: 2.83%

[0060] Y:0.31%

[0061] Ca: 0.22%

[0062] Unavoidable impurities ≤0.3%

[0063] The remainder is Mg.

[0064] Its preparation process is as follows:

[0065] Step 1 Ingredients

[0066] According to the designed alloy composition, prepare pure Mg, pure Li, pure Al, pure Ca and MgY master alloy respectively; and according to the total mass of the prepared pure Mg, pure Li, pure Al, pure Ca and MgY master alloy 10% of the covering agent is prepared; the covering agent is composed of anhydrous lithium chloride and anhydrous lithium fluoride in a mass ratio of 1:1; the purity of the pure Mg is ≥99.9%, the purity of the pure Li is ≥99.9%, The purity of pure Al is ≥99.9%, the purity of pure Ca is ≥99.9%; the MgY master alloy is composed of 72.4% Mg and 27.6% Y in terms of mass percentage;

[0067] Step two casting

Embodiment 2

[0071] The alloy consists of the following components by mass percentage:

[0072] Li: 7.82%

[0073] Al: 2.93%

[0074] Y:0.45%

[0075] Ca: 0.36%

[0076] Unavoidable impurities ≤0.3%

[0077] The remainder is Mg.

[0078] Its preparation process is as follows:

[0079] Step 1 Ingredients

[0080] According to the designed alloy composition, prepare pure Mg, pure Li, pure Al, pure Ca and MgY master alloy respectively; and according to the total mass of the prepared pure Mg, pure Li, pure Al, pure Ca and MgY master alloy 10% of the covering agent is prepared; the covering agent is composed of anhydrous lithium chloride and anhydrous lithium fluoride in a mass ratio of 5:1; the purity of the pure Mg is ≥99.9%, the purity of the pure Li is ≥99.9%, The purity of pure Al is ≥99.9%, the purity of pure Ca is ≥99.9%; the MgY master alloy is composed of 76.6% Mg and 23.4% Y in terms of mass percentage;

[0081] Step two casting

Embodiment 3

[0085] The alloy consists of the following components by mass percentage:

[0086] Li: 7.66%

[0087] Al: 3.11%

[0088] Y:0.52%

[0089] Ca: 0.44%

[0090] Unavoidable impurities ≤0.3%

[0091] The remainder is Mg.

[0092] Its preparation process is as follows:

[0093] Step 1 Ingredients

[0094] According to the designed alloy composition, prepare pure Mg, pure Li, pure Al, pure Ca and MgY master alloy respectively; and according to the total mass of the prepared pure Mg, pure Li, pure Al, pure Ca and MgY master alloy 10% of the covering agent is equipped with a covering agent; the covering agent is composed of anhydrous lithium chloride and anhydrous lithium fluoride in a mass ratio of 3:1; the purity of the pure Mg is ≥99.9%, the purity of the pure Li is ≥99.9%, The purity of pure Al is ≥99.9%, and the purity of pure Ca is ≥99.9%; the MgY master alloy is composed of 75% Mg and 25% Y in terms of mass percentage;

[0095] Step 2 Casting

[0096] The gas mixed with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com