Multifunctional ultrasonic ion continuous zero-discharge dyeing machine and dyeing process thereof

An ultrasonic, zero-emission technology, applied in the continuous processing of textile materials, textile and papermaking, vibration processing, etc., can solve the problems of serious pollution COD value, large amount of water for washing, incomplete chromatography, etc., and achieve high dry and wet rubbing fastness. , Wide application, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will now be further described in conjunction with specific examples. The following examples are intended to illustrate the present invention but not to further limit the present invention.

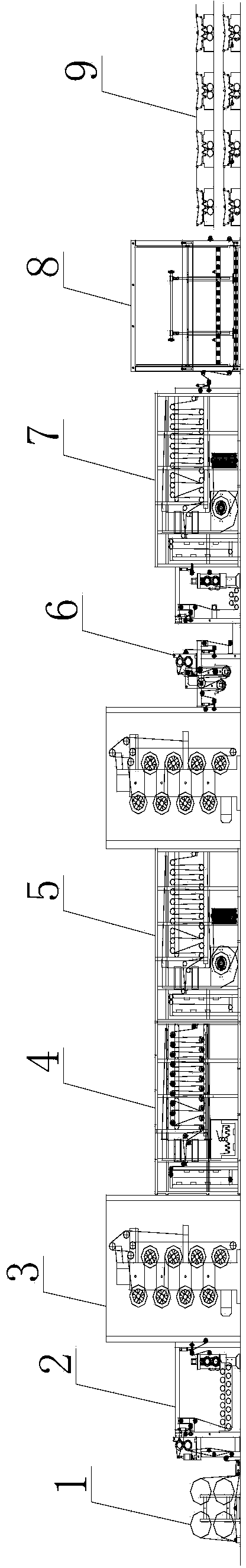

[0018] Such as figure 1 The shown multifunctional ultrasonic ion continuous zero-emission dyeing machine includes a constant tension unwinding system 1, an etherification treatment system 2, an ion reactive drying system 3, a vulcanization dyeing system 4, and the first infrared constant temperature wet short steaming system. 5. Indigo dyeing system 6, the second infrared constant temperature wet short steaming system 7, the constant tension yarn storage system 8 and the multi-unit constant tension winding system 9.

[0019] The constant tension unwinding system 1 includes a programmable logic controller, a tension sensor, a pressure sensor, an air cylinder, and a proportional valve. The output end of the tension sensor is electrically connected to the input end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com