Wireless power supply system and control method thereof of drive trolley type used for peripheral drive rake thickener

A technology of wireless power supply and peripheral transmission, applied in electromagnetic wave systems, circuit devices, electrical components, etc., can solve problems such as heavy maintenance workload, low economic benefits, and poor safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: The present invention includes a wireless power supply system and a control method for a transmission trolley for a peripheral transmission rake thickener. The specific scheme is as follows:

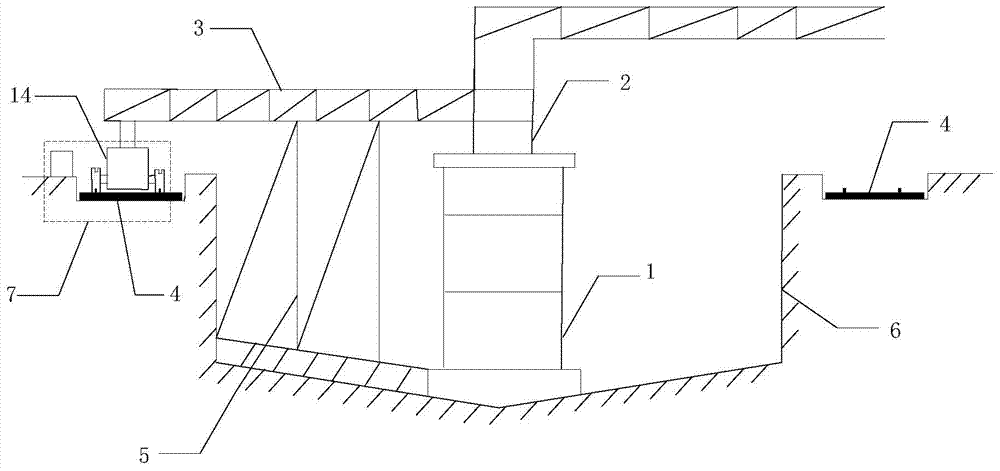

[0032] figure 1 It is a schematic diagram of the structure of the peripheral drive rake thickener. The overall structure of the rake thickener includes the central cylinder 1, the central column 2, the transmission frame 3, the track 4, the rake frame 5, the thickening tank 6, the wireless power supply system 7, etc., in which the track 4 is laid Extend the thickening tank 6 and go around the thickening tank 6 once.

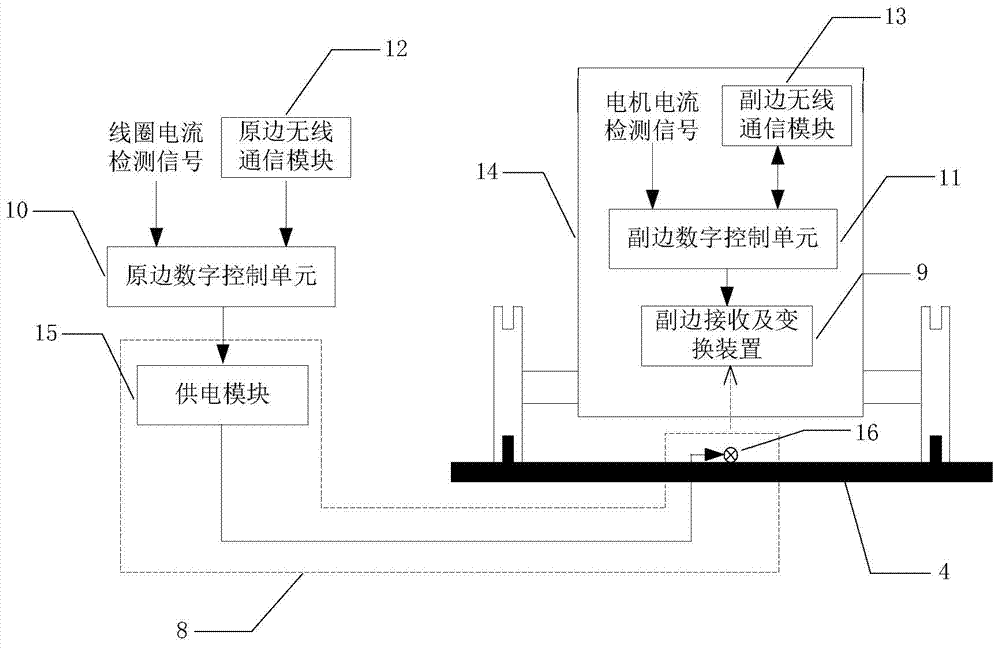

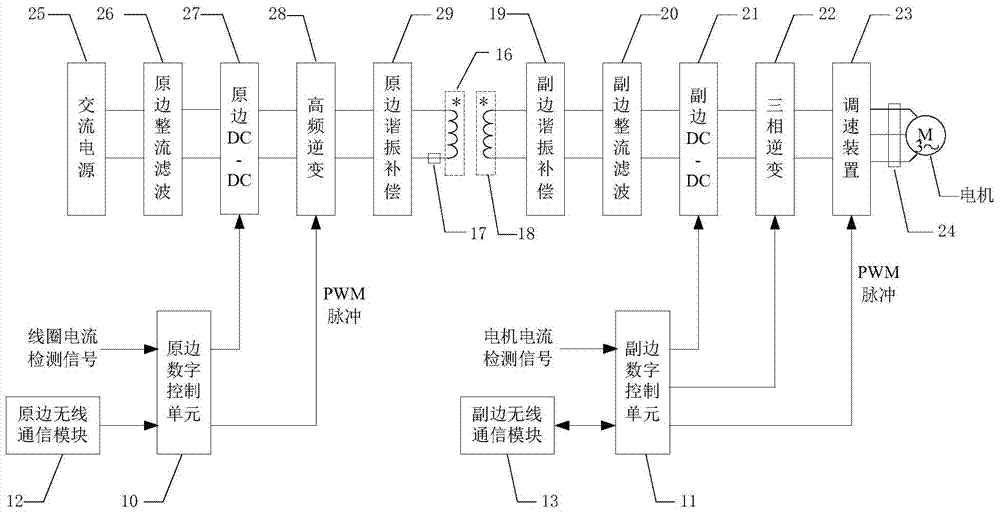

[0033] figure 2 The middle wireless power supply system 7 consists of a primary side power supply device 8, a secondary side receiving and converting device 9, a primary side digital control unit 10, a secondary side digital control unit 11, a primary side wireless communication module 12, a secondary side wireless communication module 13, and a transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com