Booster-flyback convertor of built-in switch coupling inductance

A technology of flyback converters and coupled inductors, applied in electrical components, output power conversion devices, etc., can solve the voltage peak of the transformer winding power switch tube, increase the current stress of the switch tube and diode, and turn on and off the switch tube Large loss and other problems, to achieve the effect of less power loss, reduced turn-on and turn-off losses, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

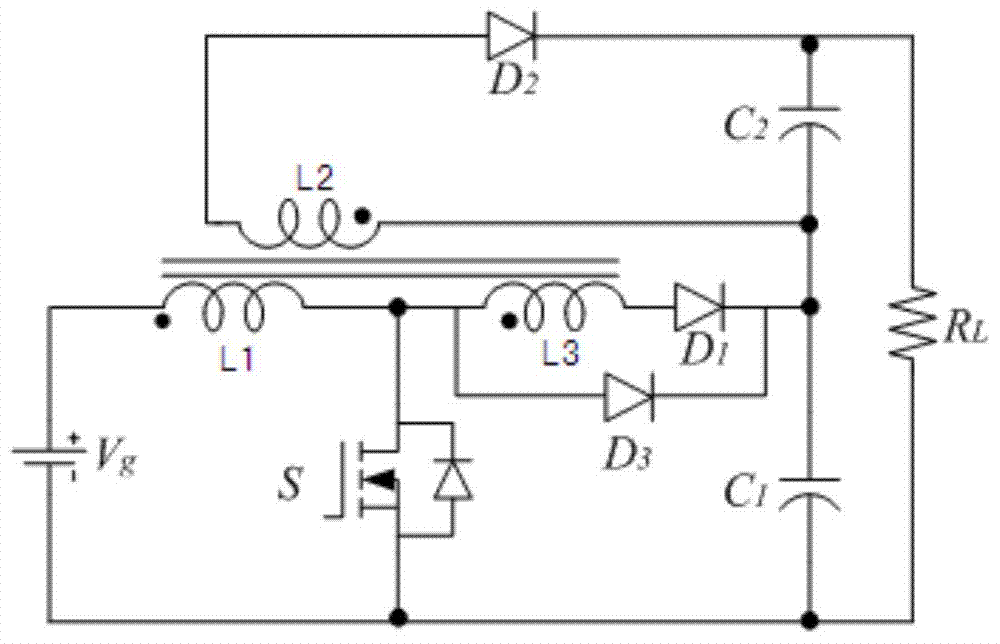

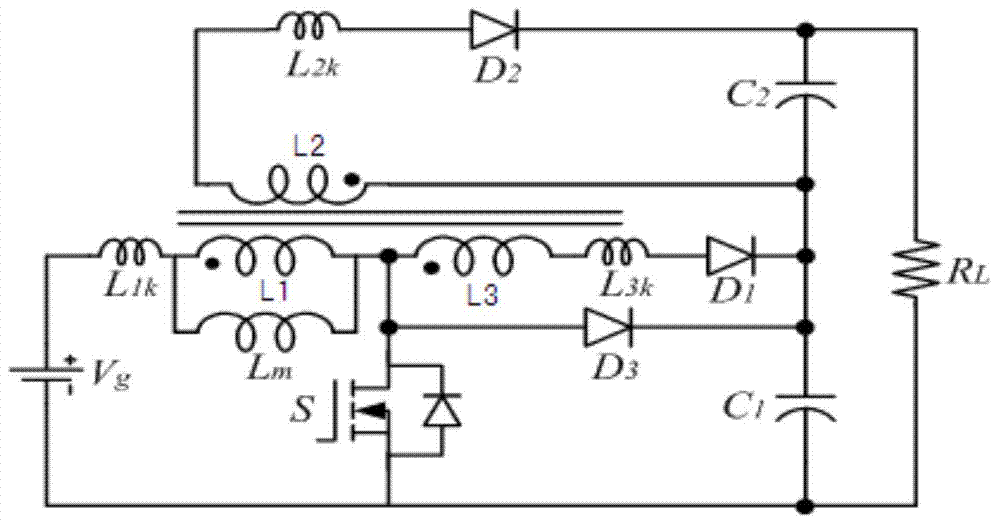

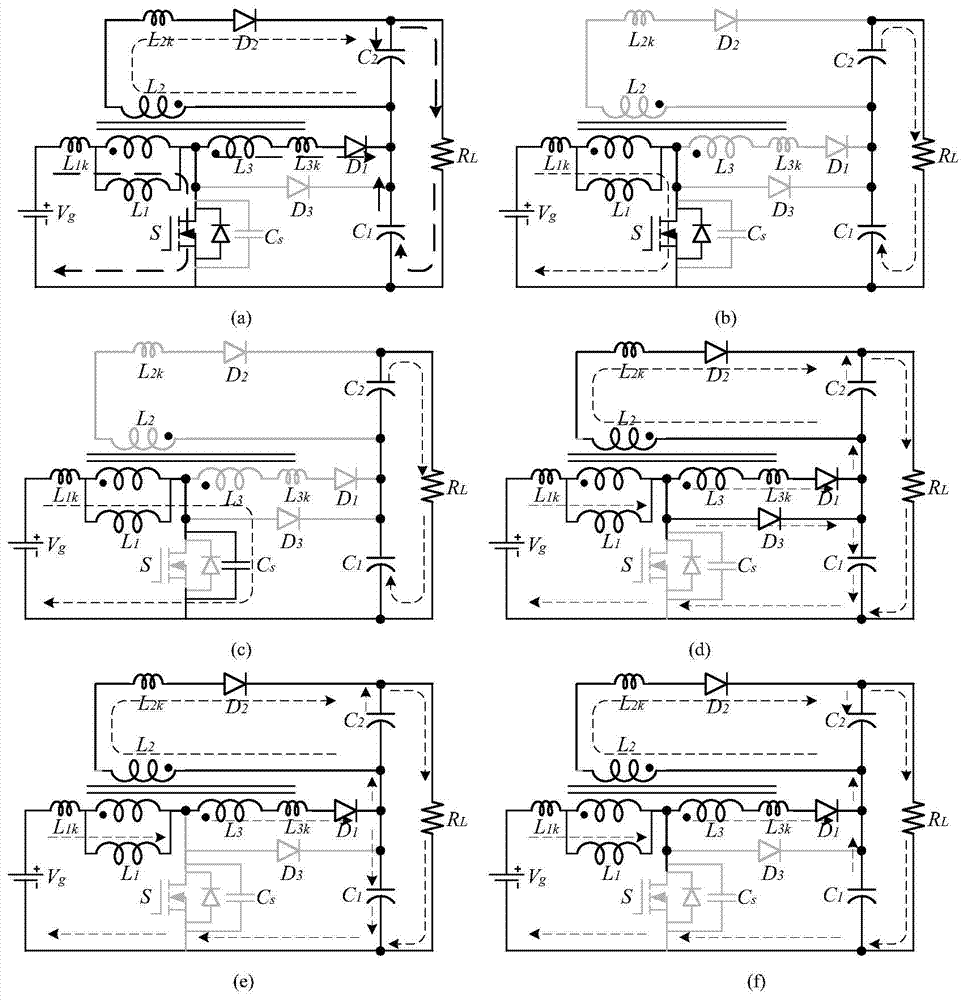

[0011] The schematic diagram of the electrical principle of this embodiment is as figure 1 As shown, the boost-flyback converter with built-in switch coupling inductor consists of a boost module and a flyback module; the boost module includes a DC power supply V g , the first winding L 1 , the third winding L 3 , power switch tube S, freewheeling diode D 1 , clamping diode D 3 and the first output capacitor C 1 ; DC power supply V g The positive terminal and the first winding L 1 The terminal of the same name is connected, the DC power supply V g The negative terminal is connected to the source of the power switch tube S, and the first output capacitor C 1 of the negative terminal and the load R L One end is connected; the first winding L 1 The opposite terminal of the power switch tube S and the drain of the clamping diode D 3 anode and tertiary winding L 3 One end is connected; the third winding L 3 The other end of the freewheeling diode D 1 The anode is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com