Production method for preparing acetic acid through carbonylation of methanol

A technology of methanol carbonylation and production method, which is applied to the preparation of carboxylic acid by carbon monoxide reaction, chemical instruments and methods, separation/purification of carboxylic acid compounds, etc., can solve the problems of complex production process, multiple equipment and operation control points of the whole set of equipment , to achieve the effect of reducing the number and cost of equipment, reducing equipment and control units, and simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] This embodiment is used to illustrate the production method of methanol carbonylation to produce acetic acid provided by the present invention.

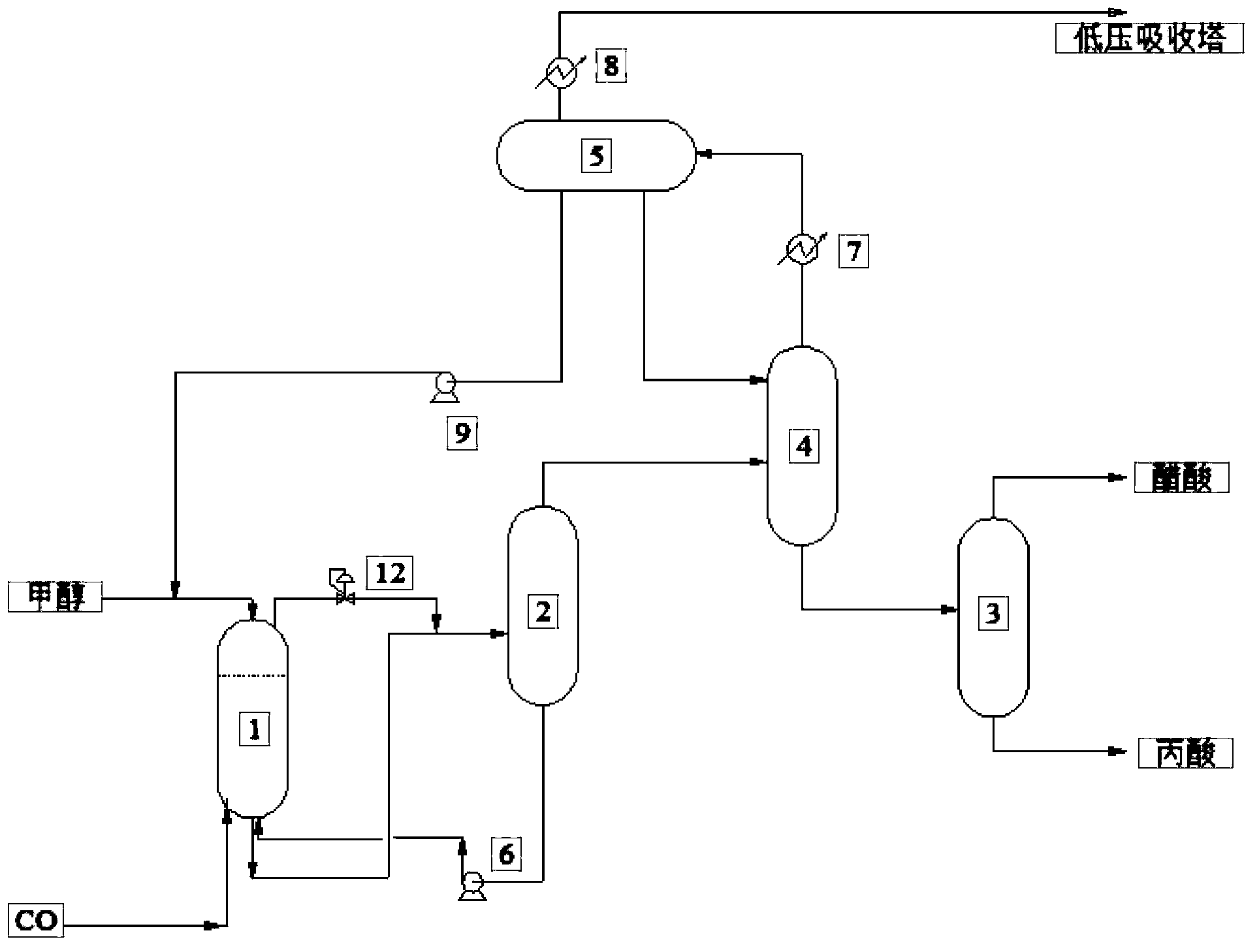

[0064] according to figure 1 The process flow shown carries out the production of methanol carbonylation to acetic acid.

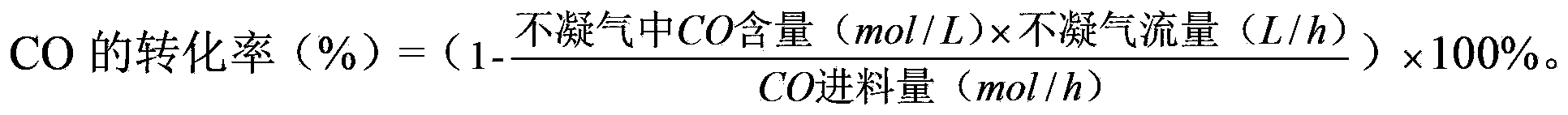

[0065] (1) Carbonylation reaction. In reactor 1 (zirconium material), put the reaction solution that catalyst and solvent are mixed into, wherein based on the total weight of catalyst and solvent, Rh containing 200 wtppm, Ir of 1500 wtppm, Ru of 2000 wtppm, 8% by weight of methyl iodide, 5% by weight of water, 12% by weight of methyl acetate, and the remainder being acetic acid. The materials methanol and CO are continuously fed into the reaction kettle 1 (zirconium material) according to the molar ratio of 1:1.05-1.15, contact with the reaction liquid in the reaction kettle 1, and carry out the carbonylation reaction under the carbonylation reaction conditions, the reaction The temperature is 190°C, an...

Embodiment 2

[0071] This embodiment is used to illustrate the production method of methanol carbonylation to produce acetic acid provided by the present invention.

[0072] according to figure 1 The process flow shown carries out the production of methanol carbonylation to acetic acid.

[0073] (1) Carbonylation reaction. In reactor 1 (zirconium material), put the reaction solution that catalyst and solvent are mixed into, wherein based on the total weight of catalyst and solvent, Rh containing 150 wtppm, Ir of 2000 wtppm, Ru of 1500 wtppm, 10% by weight of methyl iodide, 6% by weight of water, 13% by weight of methyl acetate, and the remainder being acetic acid. The materials methanol and CO are continuously fed into the reaction kettle 1 (zirconium material) according to the molar ratio of 1:1.05-1.10, contact with the reaction liquid in the reaction kettle 1, and carry out the carbonylation reaction under the carbonylation reaction conditions, the reaction The temperature is 188°C, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com