Laser centering measure system and centering measure method thereof

A laser centering and measurement system technology, applied in the field of measurement, can solve problems such as low efficiency, irreversibility, and image instability, and achieve the effects of improving work efficiency, reducing environmental requirements, and avoiding human errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

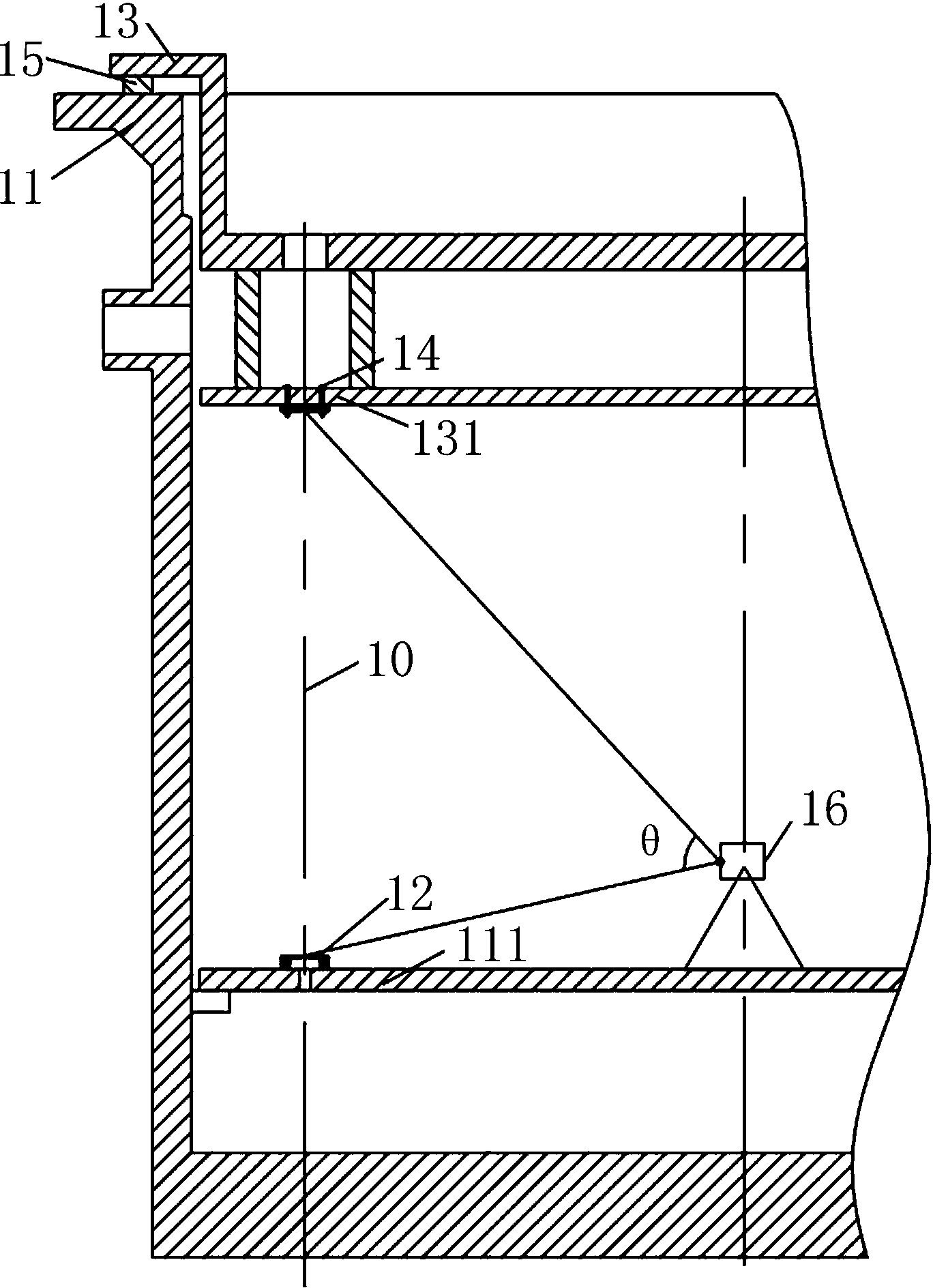

[0018] The invention is a novel space coordinate measuring system based on laser technology and automatic control technology. The laser emitted by the tracking head of the laser tracker tracks the target reflector; the space of the target reflector in the spherical coordinate system is determined by the dual-axis angle measurement system and the laser interference ranging system (or infrared absolute ranging) of the laser tracker Coordinates; the internal system error and atmospheric environment error are compensated by the calibration parameters of the laser tracker itself and the meteorological sensor, so as to obtain more accurate spatial coordinates; the laser tracker has the characteristics of thermal symmetry, high stability and large measurement range, based on Infrared light pulse reflection beat frequency counting is used for absolute distance measurement, and the accuracy is as high as 0.03mm within 10m, so it can meet the final alignment accuracy requirement of 0.25m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com