Technology for processing fried broad beans

A processing technology and broad bean technology, applied in the field of processing technology of fried broad bean, can solve the problems of inferior product quality, low production efficiency, poor sanitation conditions, etc., and achieve the effects of delaying oil rancidity, improving production efficiency and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Take the broad beans after removing impurities and cleaning, cook them at 80°C for 2 minutes, and then remove them;

[0038] (2) The obtained broad beans are dehydrated by centrifugation at 940 rpm, so that the water content is reduced to no more than 45%;

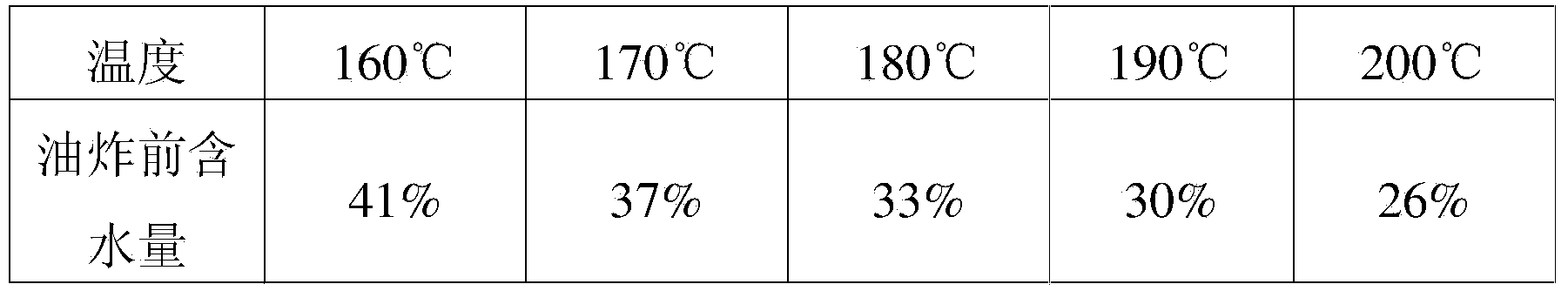

[0039] (3) Pre-fried and dewatered: spray high-temperature oil (vegetable palm oil) on broad beans, control the oil temperature 190 ℃ of spraying, time 3 minutes, make its water content be reduced to 30%;

[0040] (4) Fried the broad beans obtained, controlling the oil temperature to 176° C. for 7 minutes (using vegetable soybean oil);

[0041] (5) The broad beans obtained are centrifugally deoiled, and the centrifugal speed is controlled to be 60 rpm for 45 seconds;

[0042] (6) Add seasoning (thirteen spices, 5% of the weight of the broad beans) to the obtained broad beans and stir evenly; specifically, put the broad beans into a blender and stir, and put the powdery seasoning into the blender through a high-...

Embodiment 2

[0045] (1) Take broad beans after removing impurities and cleaning them, cook them in water at 75°C for 3 minutes, and then fish them out;

[0046] (2) The obtained broad beans are dehydrated by centrifugation at 940 rpm, so that the water content is reduced to no more than 45%;

[0047] (3) pre-fried water removal: spray high-temperature oil (vegetable palm oil) on broad beans, control the oil temperature 180 ℃ of spraying, time 3.5 minutes, make its water content be reduced to 33%;

[0048] (4) Fried the broad beans obtained, controlling the oil temperature to 175° C. for 9 minutes (using vegetable soybean oil);

[0049] (5) The obtained broad beans are centrifugally deoiled, and the control centrifugal speed is 60 rpm for 40 seconds;

[0050] (6) Add seasoning to the broad beans obtained (the amount of thirteen spices is 4% of the weight of the broad beans) and stir evenly; specifically, put the broad beans into a blender and stir, and put the powdery seasoning into the bl...

Embodiment 3

[0053] (1) After removing impurities and washing, the broad beans are steamed and boiled for 1.5 minutes at a water temperature of 80° C., and then fished out;

[0054] (2) The obtained broad beans are dehydrated by centrifugation at 940 rpm, so that the water content is reduced to no more than 45%;

[0055] (3) Pre-fried and dewatered: spray high-temperature oil (vegetable palm oil) on broad beans, control the oil temperature 190 ℃ of spraying, time 3 minutes, make its water content be reduced to 30%;

[0056] (4) Fried the broad beans obtained, controlling the oil temperature to 176° C. for 7 minutes (using vegetable soybean oil);

[0057] (5) The obtained broad beans are centrifugally deoiled, and the centrifugal speed is controlled to be 60 rpm for 35 seconds;

[0058] (6) Add seasoning (thirteen fragrances, such as Wang Shouyi Thirteen Fragrances, the dosage is 3% of the weight of the broad beans) to the obtained broad beans and stir evenly; specifically, put the broad b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com