Double-screw extruder for physical foaming of carbon dioxide EPE

A twin-screw extruder, carbon dioxide technology, applied in the field of foamed pearl cotton processing, can solve the problems of difficulty in supplying and increasing pressure of manufacturers, and achieve the effects of reducing inventory pressure, shortening supply cycle, and shortening supply cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A carbon dioxide foamed pearl cotton includes a cotton body, and a plurality of mutually isolated air bubbles are distributed in the cotton body, and its innovation lies in that carbon dioxide gas is enclosed in the air bubbles.

[0016] A foaming agent for pearl cotton, the innovation of which is that the foaming agent for pearl cotton is liquid carbon dioxide.

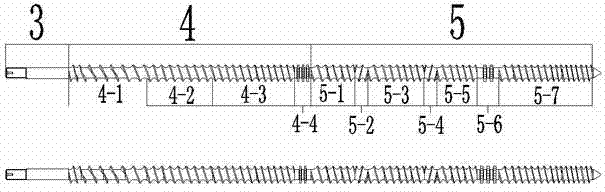

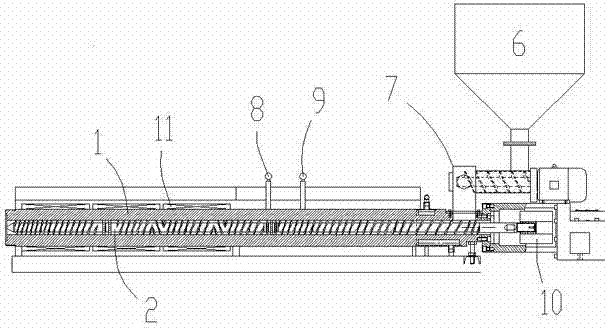

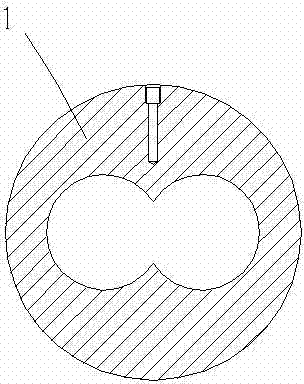

[0017] A carbon dioxide EPE physical foaming twin-screw extruder, the twin-screw extruder includes a screw barrel and two screws 2; the two screws 2 are arranged in parallel and mesh with each other, and the screw barrel 1 is provided with a The installation hole, two screw rods 2 are socketed in the installation hole; the axial direction of the screw rod 2 forms the transmission section 3, the compression homogenization section 4 and the mixing cooling section 5 in turn, and its innovation lies in: the mixing cooling section 5 In the axial direction, the first mixing section 5-1, the first reverse flow sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com