Method for granulating, molding and calcining ground phosphorite

A technology of phosphate rock powder and phosphate rock, applied in the field of phosphorus chemical industry, can solve the problems of cumbersome, difficult to control the chemical composition of finished products and wastes, and many raw materials to be added, so as to achieve the effect of efficient comprehensive utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

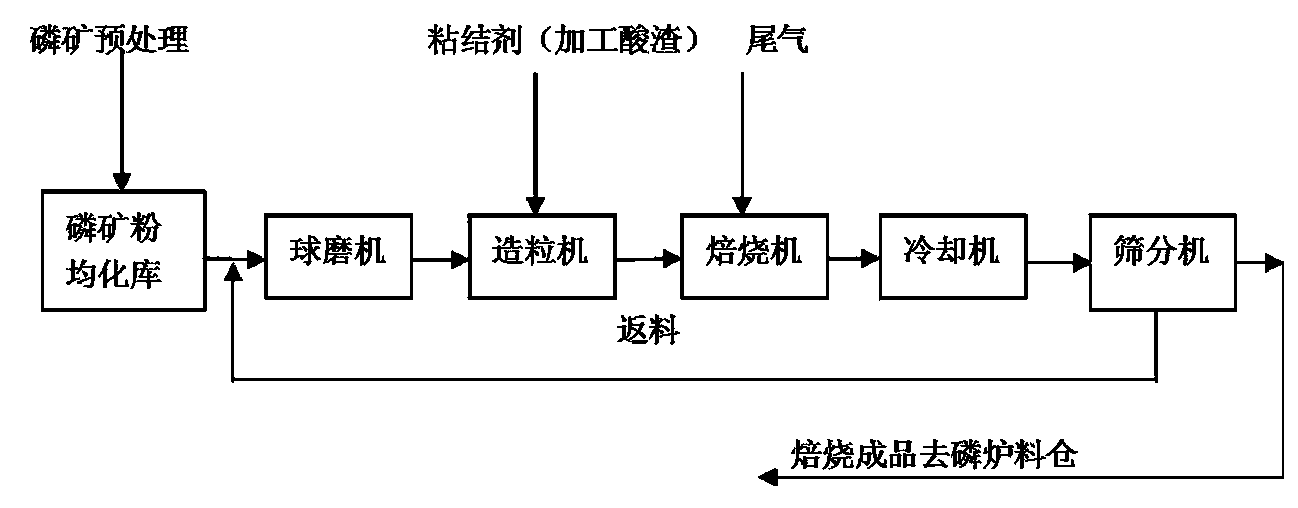

Embodiment 1

[0011] A method for granulating and roasting phosphate rock powder. After the phosphate rock is crushed, screened, dried and homogenized, it is made into phosphate rock powder with a water content of 5% by weight and a particle size of ≤10mm, and then sent to a ball mill. After the phosphate rock is ground to a particle size of ≤0.1mm, it is added to a disc granulator, and the acid slag, an intermediate product produced by the dihydrate method wet-process phosphoric acid, is evenly added. The weight percentage of solids is 15%, P 2 o 5 The weight percentage is 46% of the binder, and the weight ratio of the binder to the phosphate rock powder is 3:7, so that the phosphate rock powder is bonded to each other and made into phosphate rock pellets with a particle size of 20mm. The chain grate roaster is fed with the tail gas of the phosphorus furnace, roasted at 850°C for 20 minutes, and then enters the chain grate cooler, and the temperature is cooled to below 70°C by air cooling,...

Embodiment 2

[0013] A method for granulating and roasting phosphate rock powder. After crushing, sieving, drying and homogenizing pretreatment, the phosphate rock powder is made into phosphate rock powder with a water content of 7% by weight and a particle size of ≤10 mm, which is sent into a ball mill. After the phosphate rock is ground to a particle size of ≤0.1mm, it is added to a disc granulator, and the acid slag, an intermediate product produced by the dihydrate wet process phosphoric acid, is evenly added. The weight percentage of solids is 25%, P 2 o 5 The weight percentage is 42% of the binder, and the weight ratio of the binder to the phosphate rock powder is 3:7, so that the phosphate rock powder is bonded to each other, and the phosphate rock pellets with a particle size of 25mm are made into phosphate rock pellets. The chain grate roasting machine is fed with the exhaust gas of the phosphorus furnace, roasted at 900°C for 25 minutes, then enters the chain grate cooler, and is ...

Embodiment 3

[0015] A method for granulating and roasting phosphate rock powder. After crushing, sieving, drying and homogenizing pretreatment, the phosphate rock powder is made into phosphate rock powder with a water content of 8% by weight and a particle size of ≤10mm, and is sent into a ball mill. After the phosphate rock is ground to a particle size of ≤0.1mm, it is added to a disc granulator, and the acid slag, an intermediate product produced by the dihydrate wet-process phosphoric acid, is evenly added. The weight percentage of solids is 35%, P 2 o 5 The weight percentage is 36% of the binder, and the weight ratio of the binder to the phosphate rock powder is 3:7, so that the phosphate rock powder is bonded to each other and made into a phosphate rock pellet with a particle size of 30mm. Chain grate roasting machine, feed the exhaust gas of phosphorus furnace, roast at 950°C for 30 minutes, then enter the chain grate cooler, cool down to below 90°C through air cooling, and then make...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com