Hydrothermal method for preparing creamy white attapulgite

A technology of attapulgite and attapulgite clay, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of protein denaturation, vascular toxicity, liver and kidney toxicity, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

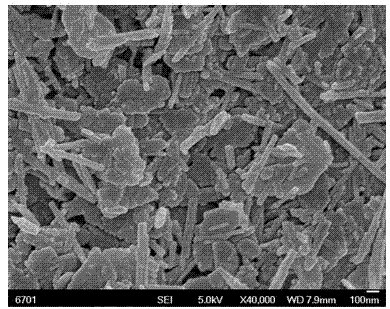

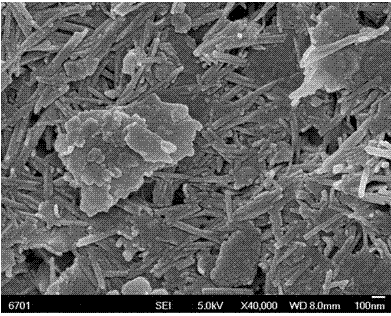

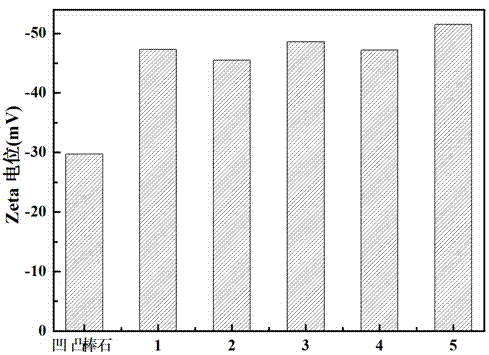

[0021] Under the stirring conditions, scattered 0.6g sulfuric acid and 0.3g sodium sodium in 600 mL of water, add 8G brick red bumps and stones to stir for 1h dispersing, and place it in 1 L high -pressure reactor.48 h, naturally cool down to room temperature. After the centrifugal and tap water was washed, it was dry, crushed, and over 200 measuring sieves to get a small red bump.The adsorption capacity of heavy metal copper ions is 105mg / g.

Embodiment 2

[0023] Under the stirring conditions, the 1.5g aminitic acid and 0.5g zinc sulfide are scattered in 600 mL water, and the 10g brick red band -rod stones are stirred and stirred for 1h.The reaction is 48 h, naturally cooling to room temperature, centrifugal, washed, dry, and crushed with tap water.After 200 mesh screens, get rice white bump sticks.The adsorption capacity of heavy metal copper ions is 108mg / g.

Embodiment 3

[0025] Under the stirring conditions, the 1.5g acetic acid and 0.8g ammonium sulfide are scattered in 600 ml of water, add 15G brick red bumps and stones to stir for 1h dispersing, and place it in 1 L high -pressure reactor.72 h, naturally cooling to room temperature, centrifugal, and washed with tap water, dry, crushed, and over 200 measuring sieves, that is, the rice white bumps are obtained.The adsorption capacity of heavy metal copper ions is 112mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com