Potassium nitrate crystallization system and process through double-decomposition method

A metathesis method and potassium nitrate technology, which is applied in the field of metathesis potassium nitrate crystallization system and crystallization process, to achieve the effects of stable vacuum control, reduced emissions, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

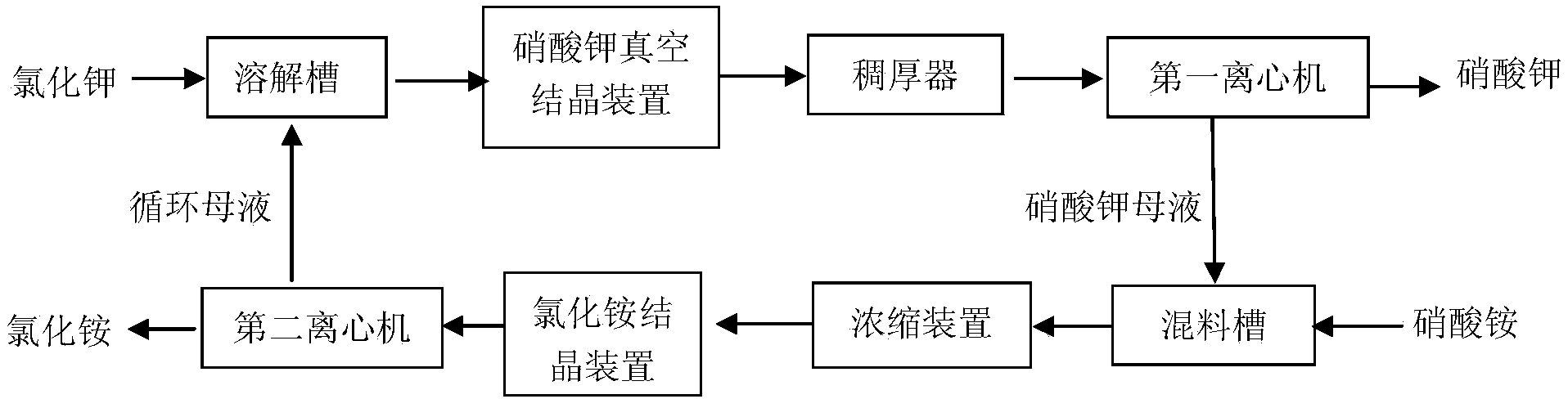

[0035] A double decomposition potassium nitrate crystallization system, the system includes a dissolution tank, a potassium nitrate vacuum crystallization device, a thickener, a first centrifuge, a mixing tank, a concentration device, a potassium chloride crystallization device and a second centrifuge, the The dissolving tank is provided with a first feed port and a second feed port, and the first centrifuge and the second centrifuge are provided with a first discharge port and a second discharge port, and the mixing tank A first feed port and a second feed port are provided;

[0036]The discharge port of described dissolving tank is connected with the feed port of potassium nitrate vacuum crystallization device, and the discharge port of described potassium nitrate vacuum crystallization device is connected with the feed port of thickener, and the feed port of described thickener The discharge port is connected with the feed port of the first centrifuge, the first discharge p...

Embodiment 2

[0040] A kind of crystallization technique of potassium nitrate utilizing the device double decomposition method described in embodiment 1, the steps are as follows:

[0041] Add circulating mother liquor, water and potassium chloride to the dissolving tank, the circulating mother liquor is ammonium chloride mother liquor, control the molar ratio of the added ammonium ions and chloride ions at 1:1, heat the dissolving tank with steam to 75°C and Stir to dissolve the material completely; the feed liquid enters the potassium nitrate vacuum crystallization device, the thickener and the first centrifuge in turn, and the water content of the thickener output is controlled at 45%;

[0042] The wet phase potassium nitrate crystals are separated from the second outlet of the first centrifuge, and the wet phase potassium nitrate crystals are dried and cooled to obtain the finished product of potassium nitrate; the potassium nitrate crystallization mother liquor is added to the mixing ma...

Embodiment 3

[0048] The metathesis potassium nitrate crystallization process as described in Example 2, the difference is: the ratio of ammonium ions to chloride ions is 1:1.1, the steam in the dissolution tank is heated to 80°C; the water content of the thickener discharge is controlled at 45 %; the mass fraction of the ammonium nitrate solution is 85%, and the quality of the ammonium nitrate solution and the quality ratio of the centrifuged mother liquor of potassium nitrate are 8:1; Ammonium crystallization temperature is controlled at 50°C.

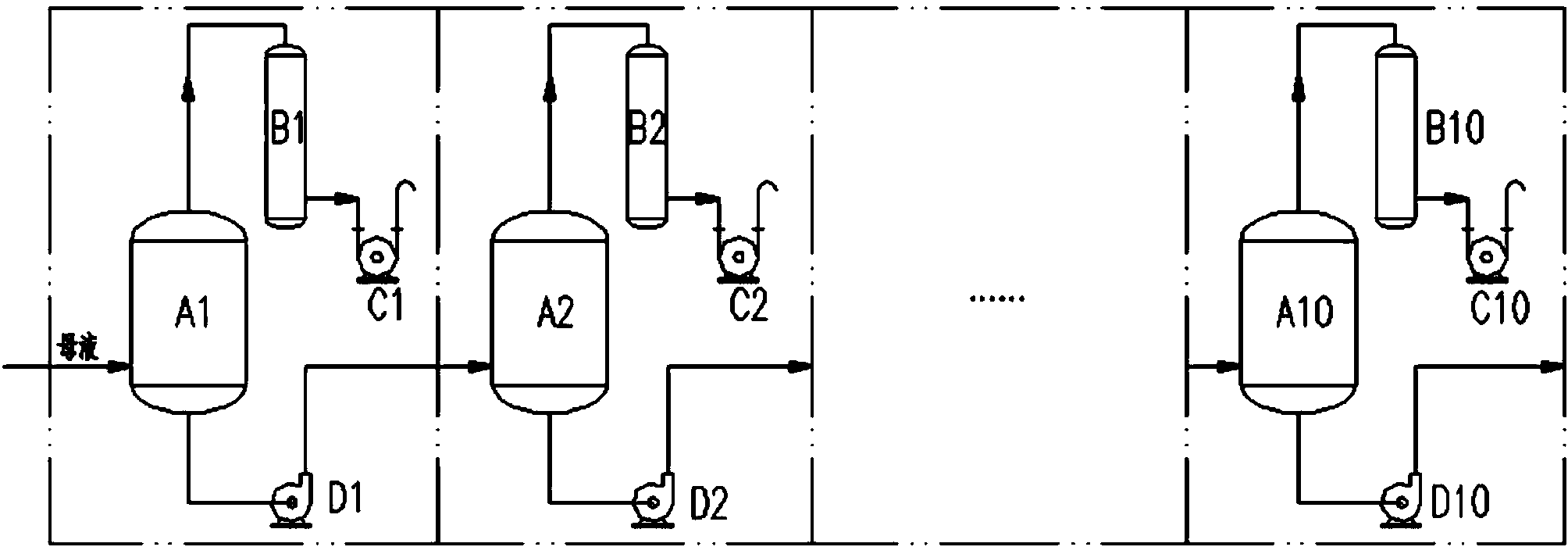

[0049] By controlling the pressure of the vacuum system at all levels, the temperature in the primary crystallizer A1 is controlled to be 75°C, the temperature in the secondary crystallizer A2 is 60°C, the temperature in the third stage crystallizer A3 is 45°C, and the temperature in the fourth stage crystallizer A4 is 38°C, the temperature in the fifth-stage crystallizer A5 is 30°C, and the temperature in the sixth-stage crystallizer A6 is 20°C. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com