Preparation method of Mn3O4 self-assembly structure

A technology of self-assembly and flower-like structure, applied in nanotechnology, nanotechnology, manganese oxide/manganese hydroxide, etc. for materials and surface science, can solve the problem of incomplete theoretical foundation and preparation technology, difficult to obtain three-dimensional structure, Complicated preparation process and other issues, to achieve the effect of strong shape controllability, low production cost, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1.1 Add 0.495 g of manganese chloride tetrahydrate and 1.457 g of sodium acetate to 12.5 mL of glycerol and 12.5 mL of water and stir until clear;

[0033] 1.2 Transfer the above solution to the reactor and react at 180 °C for 16 h;

[0034] 1.3 After the reaction, the product was obtained after centrifugation and washing.

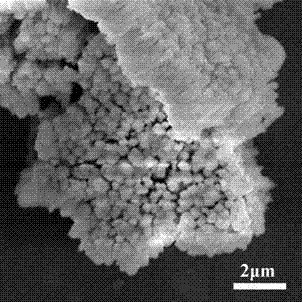

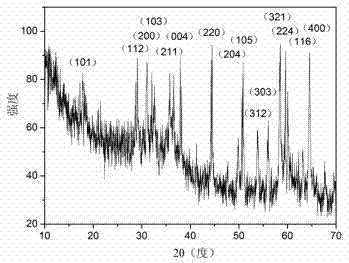

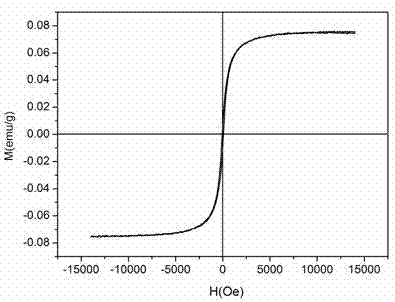

[0035] The SEM picture of the product is as follows figure 1 As shown, it can be seen from the figure that the resulting product is composed of multiple Mn with similar diameter and length 3 o 4 The rods are closely arranged in the same orientation and self-assembled into an array structure, the array surface is flat, and a single Mn 3 o 4 The diameter of the rods is 0.2-0.6 μm, the length is 1.9-3.2 μm, and the area of the self-assembled array structure is 40-80 μm 2 . The XRD pattern of the product is as follows figure 2 As shown, the XRD results are consistent with the standard XRD card (24-0734), proving that the crystal phase of the obt...

Embodiment 2

[0037] 2.1 Add 0.628 g of manganese nitrate tetrahydrate and 1.180 g of sodium acetate to 7 mL of butanetriol and 10 mL of water and stir until clear;

[0038] 2.2 Transfer the above solution to the reactor and react at 210 °C for 20 h;

[0039] 2.3 After the reaction, after centrifugation and washing, Mn with a diameter of 0.6-1.1 μm and a length of 9-15 μm was obtained. 3 o 4 Rod-like self-assembled array structure formed by closely connected rods, the area of the self-assembled array structure is 100-150 μm 2 .

Embodiment 3

[0041] 3.1 Add 0.628 g of manganese nitrate tetrahydrate and 0.620 g of sodium acetate to 11 mL of glycerol and 15 mL of water and stir until clear;

[0042] 3.2 Transfer the above solution to the reactor and react at 170 °C for 8 h;

[0043] 3.3 After the reaction, after centrifugation and washing, Mn with a diameter of 0.09-0.22 μm and a length of 0.8-2.1 μm was obtained. 3 o 4 Rod-like self-assembled array structure formed by closely connected rods, the area of the self-assembled array structure is 15-30 μm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Magnetic saturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com