Energy-saving chemical gypsum drying and calcining system

A chemical gypsum and energy-saving technology, which is applied in the field of energy-saving chemical gypsum drying and calcining systems, can solve the problems of unstable gypsum product quality, affecting the quality of downstream products, and difficulty in improving the quality, so as to delay the kiln discharge time and prolong the retention time. time, the effect of reducing the temperature of the kiln

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

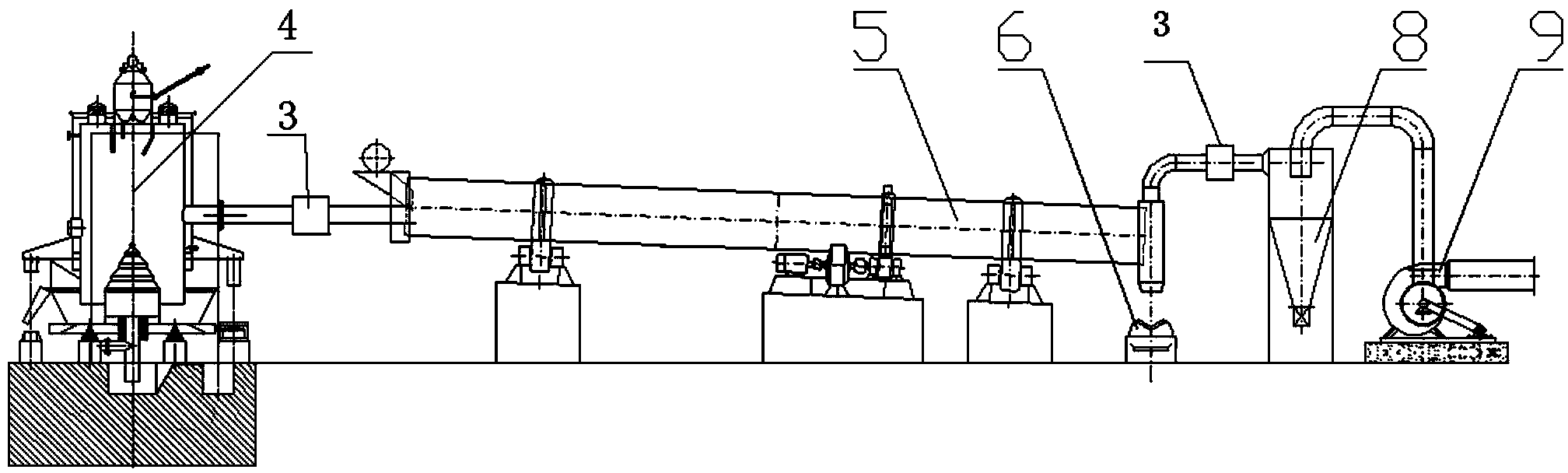

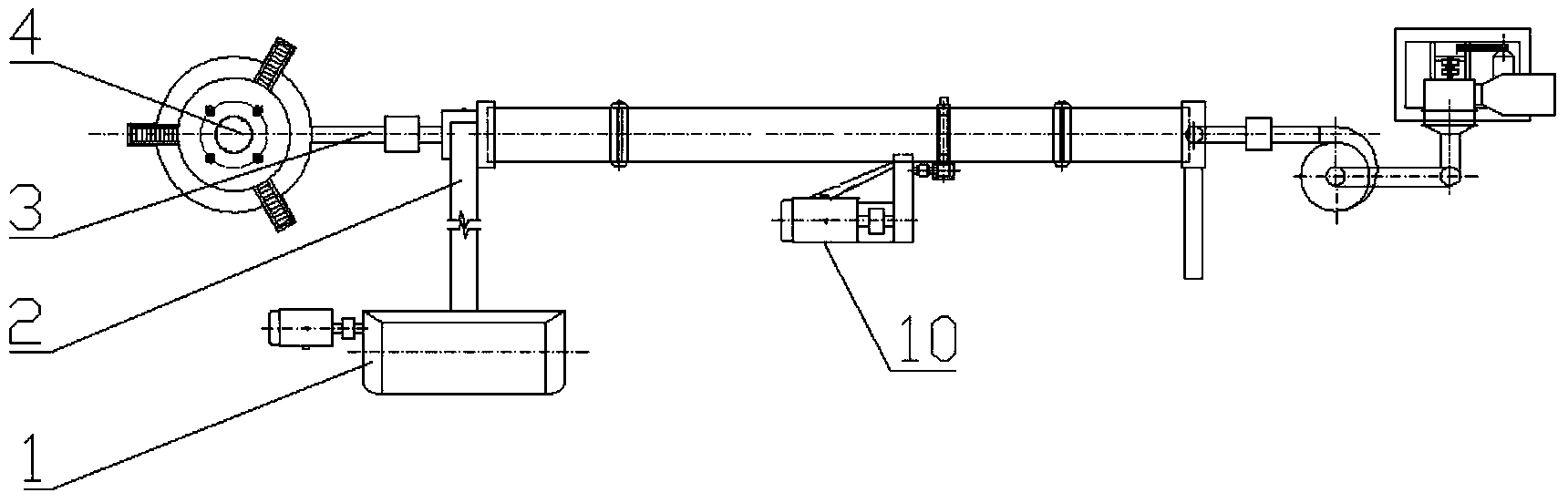

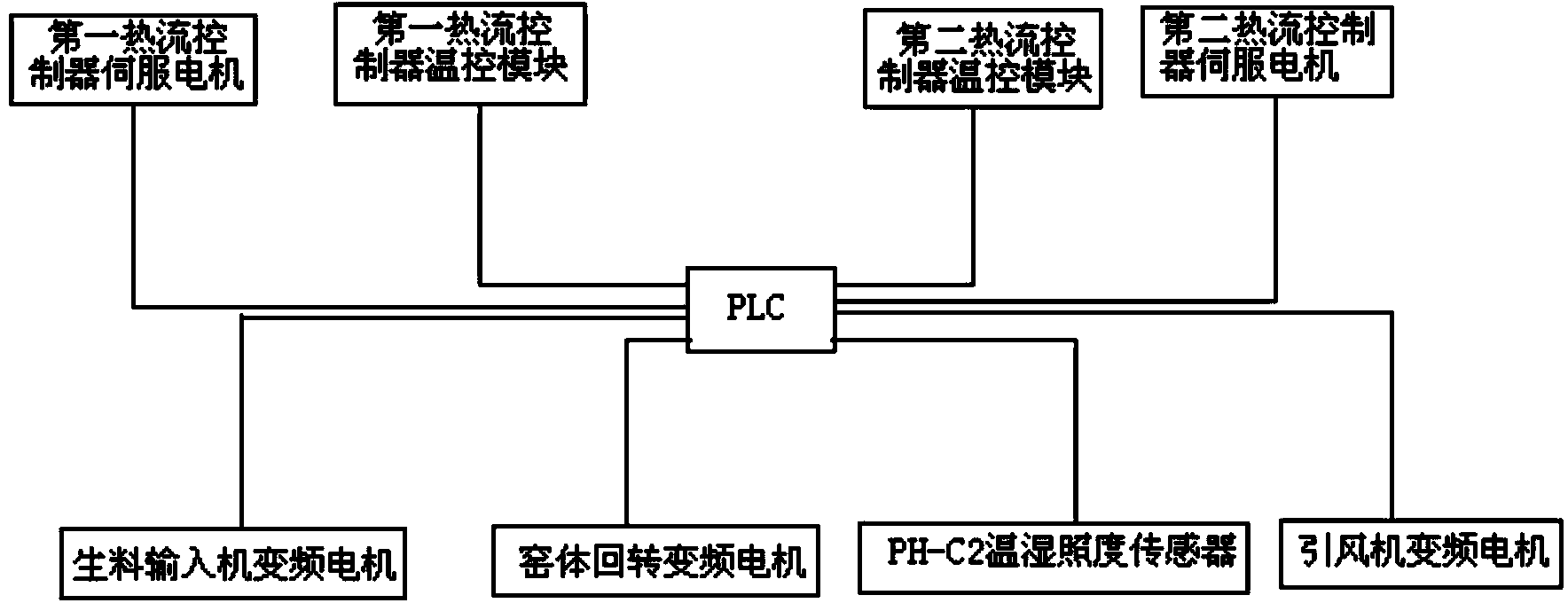

[0014] Such as Figure 1-2 As shown, an energy-saving chemical gypsum drying and calcining system includes a hot blast furnace 4, a drum drying and calcining kiln 5 connected to the hot blast furnace, and the drum drying and calcining kiln is supported on a rolling support device through a tyre. And driven by the kiln body rotary frequency conversion motor 10, the raw meal input machine 2 installed at the front end of the drum drying and calcining kiln and the raw material processing machine 1 connected to the upper end of the raw material input machine (the raw material processing machine is equipped with material scattering And homogenization device), the discharge conveyor 6, the dust collector 8, and the induced draft fan 9 are arranged in sequence at the rear end of the drum drying and calcining kiln. The first and second heat flow controllers 3 are provided between the drying and calcining kiln 5 and the hot air furnace 4 and between the drum drying and calcining kiln 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com