Waste heat recycling system and method for sintered brick tunnel kiln

A technology of waste heat recovery and tunnel kiln, which is applied in the direction of steam generation method using heat carrier, waste heat treatment, charging treatment type, etc., can solve the problems of poor cooling conditions, high energy consumption of tunnel kiln, high exhaust temperature, etc., to reduce smoke Reduced gas emissions, reduced production costs, and stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

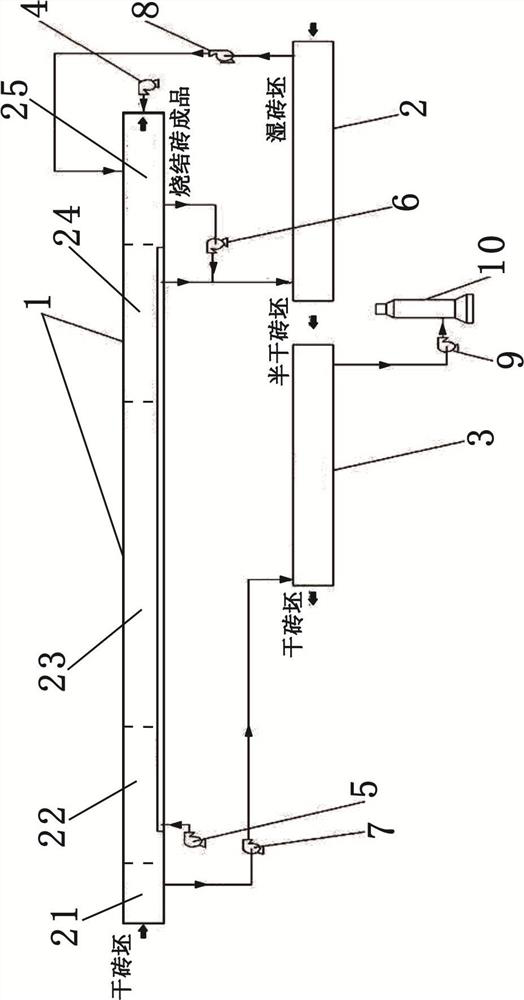

[0033] Such as figure 1 As shown, a sintered brick tunnel kiln waste heat recovery system and method, including a roasting kiln 1, the roasting kiln 1 is arranged sequentially from the front end to the rear end with a roasting kiln front end 21, a roasting kiln heating zone 22, and a roasting kiln high-temperature firing zone 23. The high-temperature quenching zone 24 of the roasting kiln and the rear end 25 of the roasting kiln. The present invention also includes a low-temperature drying kiln 2 and a high-temperature drying kiln 3 corresponding to the low-temperature drying kiln 2. A pipeline A is connected between the brick entrance end of the low-temperature drying kiln 2 and the rear end 25 of the roasting kiln, and a moisture exhaust fan is installed on the pipeline A. 8. A pipe B is connected between the brick exit end of the low-temperature drying kiln 2 and the high-temperature quenching zone 24 of the roasting kiln, and a pipe C is connected between the pipe B and th...

Embodiment 2

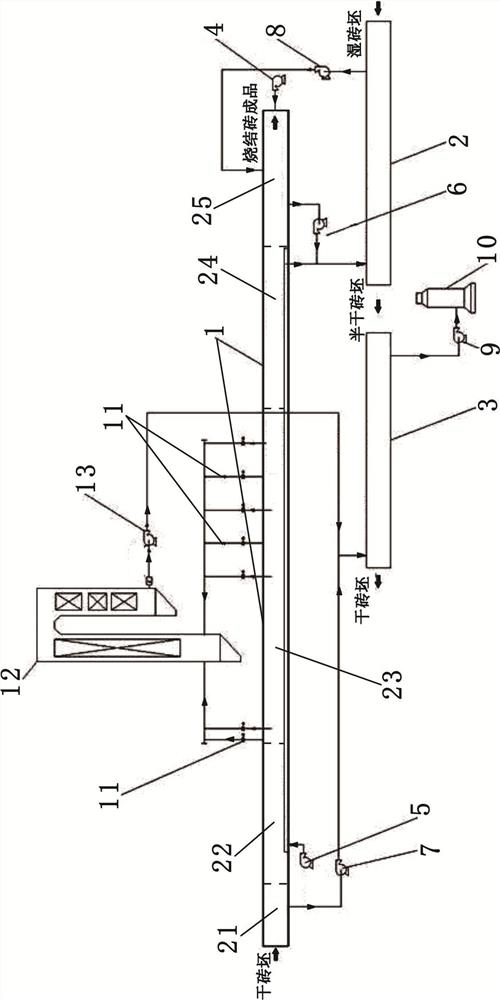

[0036] Such as Figure 2 ~ Figure 3 As shown, a sintered brick tunnel kiln waste heat recovery system and method, including a roasting kiln 1, the roasting kiln 1 is arranged sequentially from the front end to the rear end with a roasting kiln front end 21, a roasting kiln heating zone 22, and a roasting kiln high-temperature firing zone 23. The high-temperature quenching zone 24 of the roasting kiln and the rear end 25 of the roasting kiln. The present invention also includes a low-temperature drying kiln 2 and a high-temperature drying kiln 3 corresponding to the low-temperature drying kiln 2. A pipeline A is connected between the brick entrance end of the low-temperature drying kiln 2 and the rear end 25 of the roasting kiln, and a moisture exhaust fan is installed on the pipeline A. 8. A pipe B is connected between the brick exit end of the low-temperature drying kiln 2 and the high-temperature quenching zone 24 of the roasting kiln, and a pipe C is connected between the p...

Embodiment 3

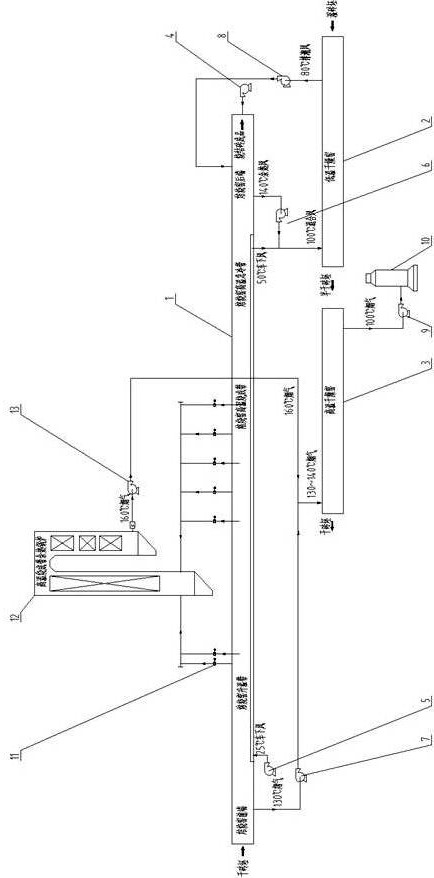

[0048] Such as Figure 1 ~ Figure 3 As shown, a smoke and wind energy-saving system of a sintered brick tunnel kiln (which is applied to the tunnel kiln production line for making bricks from low calorific value raw materials), includes a roasting kiln 1, a low-temperature drying kiln 2 for drying bricks in conjunction with the roasting kiln 1 and The high-temperature drying kiln 3, and the air blower 4 that sends normal temperature air to the rear end of the roasting kiln 1, and the undercar cooling fan 5 that sends normal temperature air to the front end of the roasting kiln 1 to cool the kiln car rollers, and extracts hot air from the rear end of the roasting kiln 1 The waste heat blower 6 to the low-temperature drying kiln 2, the roasting kiln induced draft fan 7 that extracts low-temperature flue gas from the front end of the roasting kiln 1, and the exhaust fan 8 that extracts low-temperature wind from the tidal outlet of the low-temperature drying kiln 2, and the exhaust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com