A method for improving rotary kiln and producing cement by-product yellow phosphorus or phosphoric acid

A kiln cylinder and kiln head technology, applied in the field of phosphorus chemical industry and building materials production, can solve the problems of reduced power consumption and single product, and achieve the effect of saving energy consumption, low cost and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

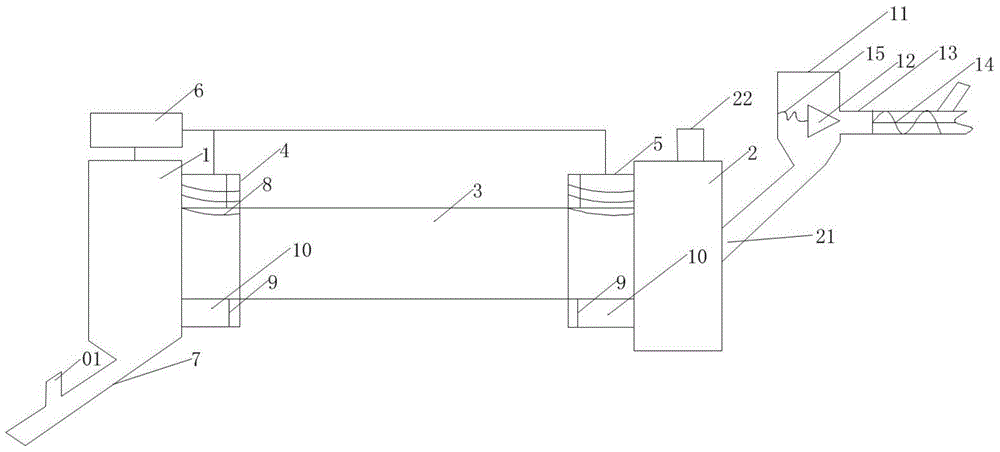

[0036] An improved rotary kiln, comprising a kiln head cover shell 1 and a kiln tail cover shell 2 arranged at both ends, a rotary kiln cylinder 3 arranged between the kiln head cover shell 1 and the kiln tail cover shell 2, setting The kiln head gas sealing device 4 between the kiln head cover shell 1 and the rotary kiln shell 3, and the kiln tail gas sealing device 5 arranged between the kiln tail cover shell 2 and the rotary kiln shell 3;

[0037] The upper part of the kiln head cover shell 1 is connected with an air supply device 6, and the air supply device 6 is connected with the kiln head air seal device 4 and the kiln tail gas seal device 5 to provide positive pressure without oxygen for the kiln head air seal chamber 10 and the kiln tail gas seal. body; the lower end of the kiln head cover shell 1 is provided with a blanking pipe gas sealing device 7, and the blanking tube gas sealing device 7 is provided with an oxygen-free gas inlet 01 for the oxygen-free gas to ente...

Embodiment 2

[0042] Similar to Example 1, the difference is that the kiln head gas sealing device 4 includes a sealing body 8 and a gas sealing retaining ring 9, the sealing body 8 is arranged on the kiln head cover shell 1, and the gas sealing retaining ring 9 is fixed on the rotary kiln The cylinder body 3 can rotate with the rotary kiln cylinder body 3, and the sealing body 8 is in sliding contact with the outer edge of the gas seal retaining ring 9 to form the gas seal chamber 10 in the kiln head gas seal device 4. The kiln head gas seal device 4 and the kiln head gas seal device 4 Tail gas sealing device 5 has the same structure, that is, kiln tail gas sealing device 5 also includes sealing body 8 and gas sealing retaining ring 9, sealing body 8 is arranged on kiln tail cover shell 2, and gas sealing retaining ring 9 is fixed on rotary kiln cylinder body 3 The top can rotate with the rotary kiln cylinder 3, and the sealing body 8 is in sliding contact with the outer edge of the gas sea...

Embodiment 3

[0049] P in phosphate rock 2 0 5 content 6-31%, calcium oxide content 36-48%, Si0 in silica 2 content of 75-99%, anthracite, and C content of 75-82%.

[0050] The method of simultaneously producing yellow phosphorus or phosphoric acid by-product of the cement produced by the aforementioned device, by weight, 60 parts of phosphorus-containing ore, 3 parts of silica, and 10 parts of anthracite are mixed according to the requirements of the cement production process and then evenly fed into the mill After being ground in the machine, it is sent to the rotary kiln for calcination. During calcination, carbon dioxide gas is introduced into the gas seal device 7 of the feed pipe, and then the carbon dioxide gas is delivered to the gas seal chamber 10 of the kiln head gas seal device 4 by the gas supply device 6. In the gas seal cavity 10 of the kiln tail gas seal device 5, carbon dioxide gas above atmospheric pressure is formed to prevent air from entering the rotary kiln to create...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com